Hexagon Socket Head Cap Screw

1.DIN 6912 Hexagon Socket Thin Head Cap Screws with Pilot Recess

2.Source bolt manufacturer, own factory: with price advantage, eliminating the price difference of middlemen.

3.Adopt the industry's top high-quality thickened steel, high stability and long-lasting durability.

4.Support customer customization.

5.Professional sales and after-sales service, welcome to inquire at any time.

6.Delivery on time.

Hexagon Socket Head Cap Screw: High-Strength Fasteners for Precision Applications

The hexagon socket head cap screw is a versatile, high-performance fastener commonly used in industries that require strong, secure, and precise connections. Featuring a cylindrical head with an internal hexagonal drive, the hexagon socket head cap screw is designed to withstand high torque and provide a flush, clean finish when installed. This makes it a preferred choice in mechanical, industrial, and construction applications, where reliability and strength are crucial.

What is a Hexagon Socket Head Cap Screw?

A hexagon socket head cap screw is a type of bolt that has the following key features:

A cylindrical head with a hexagonal recess designed for use with an Allen wrench or hex key.

A fully threaded shaft, which offers a strong and secure hold, ensuring maximum clamping force.

Made from high-strength materials like carbon steel, stainless steel, or alloy steel, depending on the application requirements.

These fasteners are engineered to provide a clean, professional appearance while delivering the strength needed for demanding tasks. Hexagon socket head cap screws are essential in a wide variety of sectors, from automotive to aerospace, and are known for their ability to maintain tight, secure connections even in high-vibration environments.

Key Features of Hexagon Socket Head Cap Screws

High Strength and Durability

The hexagon socket head cap screw is engineered to handle high torque applications. Made from robust materials such as carbon steel or stainless steel, these fasteners offer excellent tensile strength and resistance to wear, ensuring that the connection remains intact under stress.Flush-Mounted Design

The hexagon socket head allows the screw to sit flush with the surface, making it ideal for applications where protruding fasteners may be undesirable, such as machinery and electrical panels.Easy Installation

The internal hexagonal drive of the hexagon socket head cap screw allows for precise torque application with an Allen key or hex wrench, making installation quick and easy. This also reduces the risk of damage to the fastener or surrounding material during installation.Corrosion Resistance

For applications in harsh environments, hexagon socket head cap screws can be made from corrosion-resistant materials such as stainless steel or coated with finishes like zinc plating or black oxide. This ensures the fastener remains durable even in exposure to moisture, chemicals, and extreme temperatures.Versatility Across Industries

Hexagon socket head cap screws are widely used in various industries, including automotive, aerospace, manufacturing, and electronics. Their versatility makes them a staple for both precision and heavy-duty applications.

Common Applications of Hexagon Socket Head Cap Screws

Automotive Industry: Used in engines, chassis, and components where strong, secure connections are required.

Aerospace: Essential for assembling parts that are subject to high-stress conditions, such as aircraft and spacecraft components.

Industrial Machinery: Used for securing mechanical parts, motors, and other heavy machinery components.

Electronics: Ideal for assembly of electrical enclosures, circuit boards, and other electronic components.

Furniture Manufacturing: Often used in the assembly of metal or wooden furniture where a flush appearance is desired.

How to Install Hexagon Socket Head Cap Screws

Prepare the Hole

Ensure that the hole is appropriately sized for the hexagon socket head cap screw, with the correct diameter and depth to allow for proper engagement of the screw threads.Align the Screw

Insert the hexagon socket head cap screw into the hole, ensuring that it is aligned with the surface of the material for a tight fit.Use an Allen Key

Insert an Allen key or hex wrench into the internal hexagonal drive of the screw. Tighten the screw by applying consistent torque, ensuring that the screw is securely fastened without over-tightening.Check the Tightness

After installation, check the tightness of the screw to ensure that it has been properly secured and that there is no movement or play in the connection.

How to Choose the Right Hexagon Socket Head Cap Screw

When selecting the appropriate hexagon socket head cap screw, consider the following factors:

Material: Choose materials like carbon steel for strength, stainless steel for corrosion resistance, or alloy steel for high-performance applications.

Size and Thread Type: Ensure the screw's size and thread pitch match the requirements of the application.

Finish: Choose from various finishes such as zinc plating, black oxide, or plain for corrosion resistance or aesthetic preferences.

Length and Thread Pitch: Select the appropriate length and thread pitch to ensure a secure fit for your specific application.

Conclusion

The hexagon socket head cap screw is an essential fastener that offers high strength, ease of use, and a sleek, flush-mounted appearance. Its ability to handle high torque and provide secure, precise connections makes it indispensable in a wide range of applications. Whether you're working in automotive, aerospace, or industrial machinery, hexagon socket head cap screws provide the reliability and performance needed for long-lasting results. Their versatility, durability, and ease of installation ensure that they remain a top choice for engineers and builders around the world.

Pictures

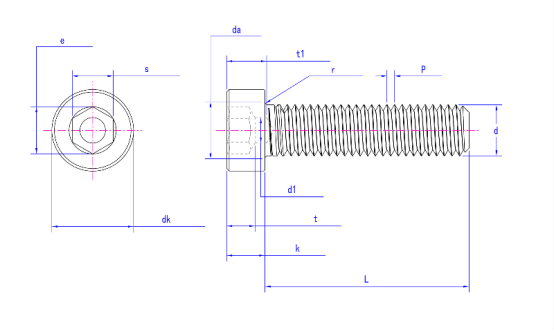

Product drawing

Product Specification

Size | M4 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | M33 | M36 | |

P | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | |

dk | max | 7 | 8.5 | 10 | 13 | 16 | 18 | 21 | 24 | 27 | 30 | 33 | 36 | 40 | 45 | 50 | 54 |

min | 6.78 | 8.28 | 9.78 | 12.73 | 15.73 | 17.73 | 20.67 | 23.67 | 26.67 | 29.67 | 32.61 | 35.61 | 39.61 | 44.61 | 49.61 | 53.54 | |

da max | 4.7 | 5.7 | 6.8 | 9.2 | 11.2 | 13.7 | 15.7 | 17.7 | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | |

d1 | min | 2 | 2.5 | 3 | 4.00 | 5.00 | 6.00 | 7.00 | 8.00 | 8 | 10 | 10 | 12 | 12 | 15 | 16.5 | 18 |

max | 2.06 | 2.56 | 3.06 | 4.075 | 5.075 | 6.075 | 7.09 | 8.09 | 8.09 | 10.09 | 10.09 | 12.11 | 12.11 | 15.11 | 16.61 | 18.11 | |

e min | 3.44 | 4.58 | 5.72 | 6.86 | 9.15 | 11.43 | 13.72 | 16.0 | 16 | 19.44 | 19.44 | 21.73 | 21.73 | 25.15 | 27.43 | 30.85 | |

k | max | 2.8 | 3.5 | 4 | 5.00 | 6.5 | 7.5 | 8.5 | 10 | 11 | 12 | 13 | 14 | 16 | 17.5 | 19.5 | 21.5 |

min | 2.66 | 3.32 | 3.82 | 4.82 | 6.28 | 7.28 | 8.28 | 9.78 | 10.73 | 11.73 | 12.73 | 13.73 | 15.73 | 17.23 | 19.17 | 21.17 | |

r min | 0.2 | 0.2 | 0.25 | 0.4 | 0.4 | 0.6 | 0.60 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | |

s | max | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 12.032 | 14.032 | 14.032 | 17.05 | 17.05 | 19.065 | 19.065 | 22.065 | 24.0625 | 27.065 |

min | 3.1 | 4.12 | 5.14 | 6.14 | 8.175 | 10.175 | 12.212 | 14.212 | 14.212 | 17.23 | 17.23 | 19.275 | 19.275 | 22.275 | 24.275 | 27.275 | |

t | min | 1.48 | 1.88 | 2.38 | 2.88 | 3.35 | 3.85 | 4.35 | 5.53 | 5.85 | 6.32 | 6.82 | 6.82 | 8.32 | 8.82 | 9.82 | 11.28 |

max | 1.72 | 2.12 | 2.62 | 3.12 | 3.65 | 4.15 | 4.65 | 5.65 | 6.15 | 6.68 | 7.18 | 7.18 | 8.68 | 9.18 | 10.18 | 11.72 | |

t1 | min | 3.3 | 4 | 5.00 | 6.5 | 7.5 | 9.00 | 10 | 11.50 | 12.5 | 14 | 15 | 16 | 17 | 19 | 20 | 24 |

max | 3.6 | 4.3 | 5.3 | 6.86 | 7.86 | 9.36 | 10.36 | 11.93 | 12.93 | 14.43 | 15.43 | 16.43 | 17.43 | 19.52 | 20.52 | 24.52 | |

Support customer customization | |||||||||||||||||