Hexagon Bolt With Flange

1.IFI 536 Hex Head Flange Bolts

2.Source bolt manufacturer, own factory: with price advantage, eliminating the price difference of middlemen.

3.Adopt the industry's top high-quality thickened steel, high stability and long-lasting durability.

4.Support customer customization.

5.Professional sales and after-sales service, welcome to inquire at any time.

6.Delivery on time.

Comprehensive Guide to Hexagon Bolt With Flange

When it comes to securing components in industrial, automotive, and structural applications, the Hexagon Bolt With Flange stands out as a versatile and high-performance fastener. This specialized bolt design combines strength, efficiency, and convenience—making it a top choice in demanding environments. In this guide, we’ll dive deep into the features, benefits, materials, applications, and industry advantages of the Hexagon Bolt With Flange.

What Is a Hexagon Bolt With Flange?

A Hexagon Bolt With Flange is a type of bolt that features a hexagonal head and an integrated washer-like flange beneath it. This flange increases the bearing surface, evenly distributing load pressure and eliminating the need for a separate washer. As a result, the Hexagon Bolt With Flange reduces part count and speeds up the installation process while ensuring enhanced fastening reliability.

Key Features of Hexagon Bolt With Flange

Hex Head Design: Offers easy installation with standard tools.

Built-In Flange: Acts as a washer to distribute load and reduce surface damage.

Threaded Shank: Provides strong grip and secure tightening.

Optional Serrations: Some variants include serrated flanges to prevent loosening under vibration.

Advantages of Using Hexagon Bolt With Flange

1. Improved Load Distribution

Thanks to its integrated flange, the Hexagon Bolt With Flange spreads pressure over a broader area, reducing localized stress and minimizing material deformation.

2. Vibration Resistance

The flange not only supports the bolt's grip but also reduces the risk of loosening due to movement, especially in dynamic applications such as engines or heavy machinery.

3. Fast and Efficient Installation

With no need for separate washers, assembly time is reduced significantly, making the Hexagon Bolt With Flange ideal for automated production lines or time-sensitive repairs.

4. Cost-Effective

By reducing the total number of components and installation steps, this bolt contributes to lower labor and maintenance costs over time.

Common Applications of Hexagon Bolt With Flange

Due to its strength and convenience, the Hexagon Bolt With Flange is widely used in industries such as:

Automotive: Used in engines, suspensions, and chassis systems.

Construction: Ideal for steel structures and building joints.

Machinery: Secures moving parts in industrial equipment.

Railway: Ensures tight and reliable connections in high-stress applications.

Wind and Solar Energy: Used in towers and panel mounting brackets.

Materials and Finishes

To meet a wide range of environmental and mechanical demands, the Hexagon Bolt With Flange is available in multiple materials and finishes:

Carbon Steel (Grades 8.8 / 10.9 / 12.9): Offers superior tensile strength.

Stainless Steel (304 / 316): Corrosion-resistant for outdoor or marine environments.

Alloy Steel: Combines strength and toughness for critical applications.

Common surface finishes include:

Zinc Plating: Provides basic corrosion resistance.

Black Oxide: Enhances appearance and reduces glare.

Galvanized Coating: Ideal for long-term outdoor exposure.

Phosphated Finish: Improves lubricity and wear resistance.

Technical Standards

Hexagon Bolt With Flange products typically comply with international standards, including:

These standards ensure uniformity in dimensions, strength, and performance across different industries.

How to Select the Right Hexagon Bolt With Flange

When choosing a Hexagon Bolt With Flange, consider the following factors:

Tensile Load Requirements: Choose the right grade based on stress levels.

Corrosion Environment: Use stainless or galvanized variants for outdoor use.

Bolt Size and Length: Match with the material thickness and assembly depth.

Thread Type: Coarse vs. fine threading depends on the application.

Maintenance and Safety Tips

To ensure optimal performance and safety of the Hexagon Bolt With Flange:

Always use a torque wrench for consistent clamping force.

Inspect bolts regularly for signs of wear or corrosion.

Replace bolts after repeated removal to maintain thread integrity.

Why Choose a Hexagon Bolt With Flange?

Whether you're building high-performance machinery or securing steel beams in a commercial building, the Hexagon Bolt With Flange provides unmatched value. It eliminates the need for washers, accelerates installation, and offers superior joint stability even under harsh conditions.

With its unique combination of strength, convenience, and versatility, the Hexagon Bolt With Flange is an essential fastener for professionals who demand both reliability and efficiency.

Conclusion

The Hexagon Bolt With Flange is more than just a fastener—it's a solution engineered for high-stress, high-performance applications. From automotive assembly lines to infrastructure megaprojects, this bolt type ensures that critical components stay securely in place.

Make the Hexagon Bolt With Flange your go-to fastener for demanding applications where strength and speed matter most.

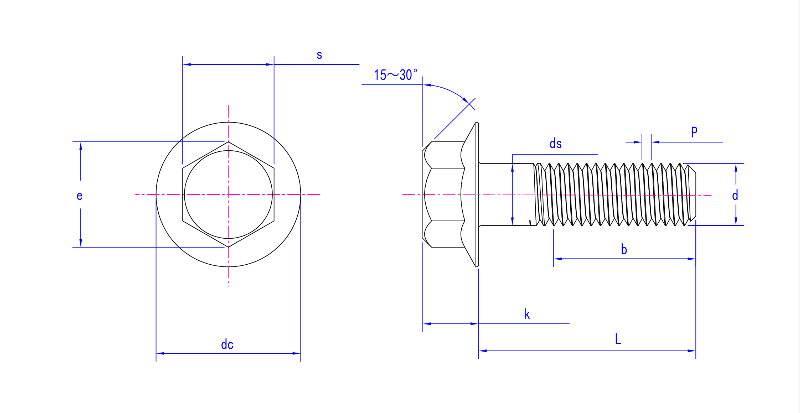

Product drawing