Hexagonal Flange Bolts

1.GB-T 16674.1 Hex Flange Bolts-Small Series

2.Source bolt manufacturer, own factory: with price advantage, eliminating the price difference of middlemen.

3.Adopt the industry's top high-quality thickened steel, high stability and long-lasting durability.

4.Support customer customization.

5.Professional sales and after-sales service, welcome to inquire at any time.

6.Delivery on time.

A Complete Guide to Hexagonal Flange Bolts: Strength, Stability, and Performance

When it comes to fastening solutions that combine structural strength with design efficiency, Hexagonal Flange Bolts stand out as an industry favorite. These bolts are widely recognized for their ability to enhance clamping power and simplify assembly, making them ideal for automotive, industrial, and mechanical applications. In this guide, we’ll break down everything you need to know about Hexagonal Flange Bolts—from their structure and benefits to their real-world applications.

What Are Hexagonal Flange Bolts?

Hexagonal Flange Bolts are fasteners with a hex-shaped head and an integrated circular flange beneath the head. This flange functions like a built-in washer, spreading the load and reducing the need for separate washers during installation. The design ensures that the bolt remains stable and provides a more secure grip over a larger area.

Key Features of Hexagonal Flange Bolts

Built-in Flange Washer

One of the defining features of Hexagonal Flange Bolts is the built-in washer that increases the bearing surface and minimizes surface damage.Time-Saving Installation

With no need for separate washers, Hexagonal Flange Bolts reduce part counts and streamline the assembly process, making them perfect for automated manufacturing lines.Superior Load Distribution

The wide flange offers even pressure distribution, which helps prevent loosening in high-vibration environments and ensures a more durable connection.Serrated vs. Smooth Flanges

Some Hexagonal Flange Bolts come with serrated flanges to grip the surface and prevent back-off during operation, while others feature smooth flanges to protect delicate surfaces.

Why Choose Hexagonal Flange Bolts?

The advantages of using Hexagonal Flange Bolts go beyond convenience:

Stronger Clamping Force: The larger surface area of the flange improves grip and stability.

Cost Efficiency: Eliminates the need for washers, reducing both material and labor costs.

Enhanced Safety: Prevents bolt loosening under dynamic loads and high torque.

Versatility: Suitable for metal-to-metal, metal-to-plastic, and even wood applications.

Applications of Hexagonal Flange Bolts

Hexagonal Flange Bolts are used across a wide range of industries due to their versatility and performance:

Automotive Sector: Engine brackets, frame joints, transmission systems, suspension components.

Heavy Machinery: Mining equipment, agricultural implements, hydraulic systems.

Construction Projects: Steel structures, HVAC systems, scaffolding, and roofing.

Home DIY and Furniture: Ideal for shelving units, mounting systems, and garage assemblies.

Materials and Finishes

To suit different environmental and performance requirements, Hexagonal Flange Bolts come in a variety of materials:

Carbon Steel: Strong and economical for general-purpose use.

Stainless Steel (304/316): Offers excellent corrosion resistance for marine and outdoor applications.

Alloy Steel (Grade 8): Ideal for high-torque, high-stress connections.

Zinc-Plated or Black Oxide Coatings: Adds rust resistance and improves visual appearance.

Choosing the Right Hexagonal Flange Bolt

When selecting Hexagonal Flange Bolts, consider these factors:

Size & Thread Pitch: Ensure compatibility with the application’s hole diameter and thread specifications.

Flange Type: Use serrated flanges for vibration-prone settings, smooth flanges for soft surfaces.

Material Compatibility: Choose a finish that complements the environment (indoor, outdoor, corrosive, etc.).

Torque Requirements: Select bolts rated to handle the torque levels of your application without stripping.

Installation Tips for Hexagonal Flange Bolts

Always clean mating surfaces before installation.

Use a torque wrench to apply correct clamping force.

For added resistance in high-vibration environments, consider thread-locking compounds.

Avoid overtightening, which may deform soft flanges or base materials.

Conclusion

Whether you're assembling an automotive engine or constructing steel structures, Hexagonal Flange Bolts offer a reliable, cost-effective, and high-performance solution. Their built-in washer design not only simplifies installation but also enhances joint integrity. When chosen and applied correctly, Hexagonal Flange Bolts can dramatically improve both the safety and longevity of any mechanical assembly.

Make Hexagonal Flange Bolts your go-to fastener for any job that demands strength, speed, and security.

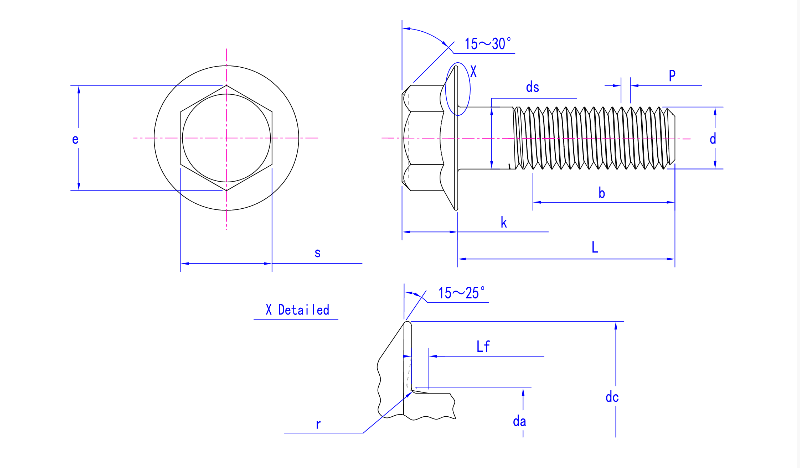

Product drawing