Socket Head Cap Screws

1.ASME/ANSI B18.3.1M-1 Socket Head Cap Screws

2.Source bolt manufacturer, own factory: with price advantage, eliminating the price difference of middlemen.

3.Adopt the industry's top high-quality thickened steel, high stability and long-lasting durability.

4.Support customer customization.

5.Professional sales and after-sales service, welcome to inquire at any time.

6.Delivery on time.

Socket Head Cap Screws: High-Strength Fasteners for Precision and Durability

Socket head cap screws are widely regarded as one of the most reliable and versatile fasteners for heavy-duty applications. Featuring a cylindrical head with an internal hexagonal drive, socket head cap screws provide a compact yet strong solution for securing components that require high torque and precise tightening. From aerospace engineering to automotive applications, socket head cap screws are essential for both strength and ease of use.

Designed for demanding environments, socket head cap screws combine high mechanical strength, ease of installation, and a sleek appearance, making them ideal for use in industrial machinery, electronics, and structural assemblies.

What Are Socket Head Cap Screws?

Socket head cap screws are fasteners characterized by:

A cylindrical head with a hexagonal socket drive (also known as an Allen drive), which requires an Allen key or hex wrench for installation.

Fully threaded shafts, providing maximum grip and clamping force in various materials.

A standardized design that adheres to industrial specifications like ISO 4762 and DIN 912, ensuring compatibility and consistency.

Typically made from high-strength steel, stainless steel, or alloy materials, socket head cap screws are used where precision, reliability, and durability are crucial.

Key Features of Socket Head Cap Screws

High Strength and Torque Resistance

Due to their robust design, socket head cap screws are ideal for applications that require high torque resistance and clamping force, such as machinery and automotive assemblies.Compact and Space-Saving Design

The socket head cap screw features a low-profile head that reduces the risk of interference in tight spaces, providing a clean, professional finish.Easy Installation and Removal

With their hexagonal drive, socket head cap screws are easy to install and remove, especially in hard-to-reach areas where traditional wrenches might be ineffective.Corrosion Resistance

Available in a variety of finishes, including zinc plating, black oxide, and stainless steel, socket head cap screws offer corrosion resistance, making them suitable for outdoor or industrial environments.Versatility Across Industries

Socket head cap screws are used in various industries, from aerospace to construction, due to their adaptability and secure performance in both high and low-pressure applications.

Common Applications of Socket Head Cap Screws

Automotive and Aerospace: Used in critical applications like engine parts, assemblies, and structural components.

Industrial Machinery: Essential for securing mechanical parts, motors, and moving components where precision is key.

Electronics and Electrical Devices: Perfect for assembling electrical panels, housings, and control units.

Construction and Infrastructure: Used in high-strength applications requiring a secure, flush-mounted finish.

How to Install Socket Head Cap Screws

Pre-drill the appropriate hole size to match the diameter of the socket head cap screw.

Align the screw with the hole and insert it into the desired position.

Tighten using an Allen key or hex wrench, applying consistent torque to ensure a secure fit.

Optionally, apply a thread-locking adhesive to ensure the screw remains tight under vibration or stress.

Proper installation of socket head cap screws ensures they remain firmly in place and contribute to the longevity and reliability of the assembly.

Selecting the Right Socket Head Cap Screws

When selecting socket head cap screws, consider the following:

Material: Stainless steel for corrosion resistance, carbon steel for strength, or alloy materials for specialized requirements.

Size and Thread Type: Available in a range of sizes from M3 to M20 or imperial equivalents.

Finish: Choose finishes like zinc plating or black oxide for corrosion protection in various environments.

Length and Thread Pitch: Ensure the screw’s length and thread pitch are suitable for the specific application.

Conclusion

Socket head cap screws are indispensable fasteners for projects that require high torque, reliability, and ease of use in confined spaces. Whether you're working on complex machinery, electronic devices, or construction projects, socket head cap screws provide the necessary strength, corrosion resistance, and precision to ensure a long-lasting and secure assembly. Their versatile design makes them the go-to fastener for demanding applications across various industries.

Pictures

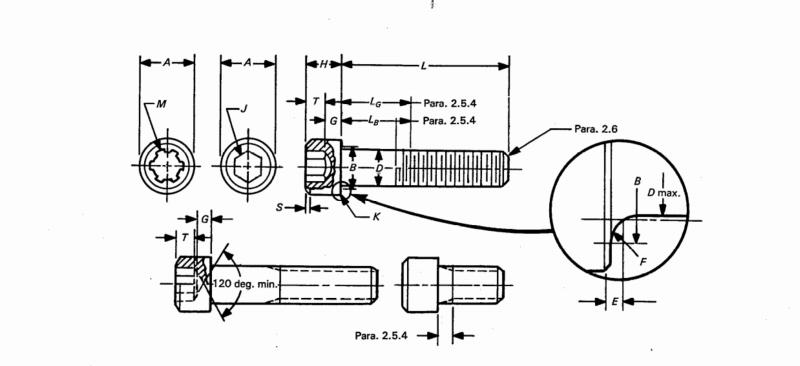

Product drawing