AS 1111.2 Fully Threaded Hexagon Head Bolts

Product: AS 1111.2 Fully Threaded Hexagon Head Bolts

Property Class:4.6,4.8,5.6,5.8,8.8,10.9,12.9,

A2-70, A4-70,A4-80

Finish:Zinc Plating(Yellow Zinc, Zinc Blue, Rinse Color), Black, Phosphate & Oil, Zinc Phosphate, Hot-dip Galvanized(HDG),Dacromet, Geomet

Material:Steel,Stainless

Export country: USA, Japan, Australia, Europe and so on

Support customer customization

AS 1111.2 fully threaded hexagon head bolt is a fastener that adheres to a specific standard (AS 1111.2). The fully threaded design means that the entire length of the bolt is threaded, unlike semi-threaded bolts (only part of the length is threaded) . This design allows the bolt to mate more effectively with nuts or other connections, providing stronger tightening force. The head of the bolt is hexagonal, making it easier to rotate and tighten the bolt. The fully threaded design allows the threads to be firmly locked on the part and not easy to loosen, which is especially important in applications where long-term tightening force is required.

Pictures

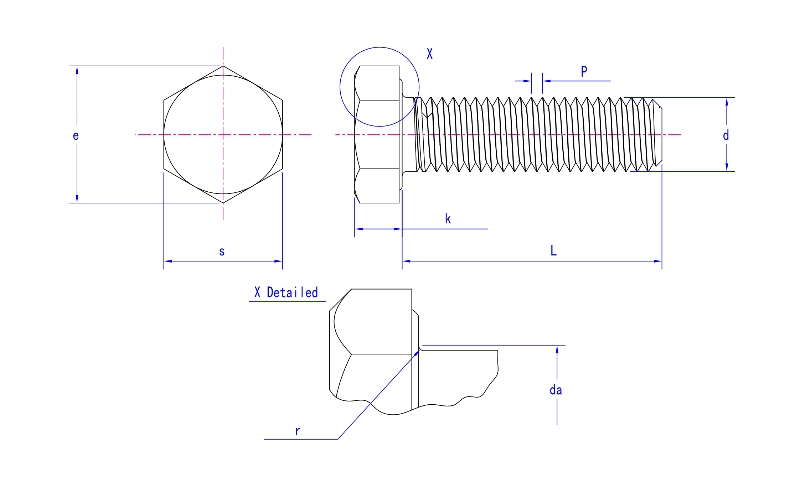

Product drawing

Product Specification

Size | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | M33 | M36 | M39 | M42 | M45 | M48 | M52 | M56 | M60 | M64 | |

P | 0.8 | 1.0 | 1.25 | 1.5 | 1.75 | 2.0 | 2.0 | 2.5 | 2.5 | 2.5 | 3.0 | 3.0 | 3.5 | 3.5 | 4.0 | 4.0 | 4.5 | 4.5 | 5.0 | 5.0 | 5.5 | 5.5 | 6.0 | |

da max | 6.0 | 7.2 | 10.2 | 12.2 | 14.7 | 16.7 | 18.7 | 21.2 | 24.4 | 26.4 | 28.4 | 32.4 | 35.4 | 38.4 | 42.4 | 45.4 | 48.6 | 52.6 | 56.6 | 62.6 | 67.0 | 71.0 | 75.0 | |

e min | 8.63 | 10.89 | 14.2 | 17.59 | 19.85 | 22.78 | 26.17 | 29.56 | 32.95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | 76.95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 | |

k | max | 3.875 | 4.375 | 5.675 | 6.85 | 7.95 | 9.25 | 10.75 | 12.4 | 13.4 | 14.9 | 15.9 | 17.9 | 19.75 | 22.05 | 23.55 | 26.05 | 27.05 | 29.05 | 31.05 | 34.25 | 36.25 | 39.25 | 41.25 |

min | 3.125 | 3.625 | 4.925 | 5.95 | 7.05 | 8.35 | 9.25 | 10.6 | 11.6 | 13.1 | 14.1 | 16.1 | 17.65 | 19.95 | 21.45 | 23.95 | 24.95 | 26.95 | 28.95 | 31.75 | 33.75 | 36.75 | 38.75 | |

r min | 0.2 | 0.25 | 0.4 | 0.4 | 0.5 | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.2 | 1.2 | 1.6 | 1.6 | 2.0 | 2.0 | 2.0 | |

s | max | 8.0 | 10.0 | 13.0 | 16.0 | 18.0 | 21.0 | 24.0 | 27.0 | 30.0 | 34.0 | 36.0 | 41.0 | 46.0 | 50.0 | 55.0 | 60.0 | 65.0 | 70.0 | 75.0 | 80.0 | 85.0 | 90.0 | 95.0 |

min | 7.64 | 9.64 | 12.57 | 15.57 | 17.57 | 20.16 | 23.16 | 26.16 | 29.16 | 33.0 | 35.0 | 40.0 | 45.0 | 49.0 | 53.8 | 58.8 | 63.1 | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 | |

Support customer customization | ||||||||||||||||||||||||

Some introduction about our company

Application

Our products are widely used in mechanical, electrical, automotive, building construction, railways, bridges, steamships, fire protection and communication system, etc.

Workshop

Certification

Through scientific management, Jinan Star Fastener Co., Ltd. has obtained the 2015 version of ISO9001 quality management system certification. In 2017, the laboratory passed the national CNAS certification. In 2018, the company passed the European CE certification.

Testing Equipment

Our company has a specialized laboratory with digital hardness testers, microscopes, universal testing machines, axial force meters, hydrogen embrittlement detection devices, magnetic particle flaw detectors, metallographic analyzers, carbon and sulfur analyzers and salt spray testing machines, etc. Experimental testing equipment is used to conduct comprehensive testing of the chemical composition of raw materials, product hardness, mechanical properties, coating thickness and corrosion resistance to ensure that all products meet standard requirements and satisfy customers.

Production equipment

Our company has more than 300 production equipment.The product production process includes: Annealing, shot blasting, cold heading, thread rolling, heat treatment, galvanizing, finished product testing, packaging, etc. are all completed in the company.

Packing

Service

1. Inventory management and order tracking. Manufacturers can provide inventory management services to ensure the timely supply of bolts required by customers.

Provide order tracking services so that customers can understand the order processing progress and logistics information in real time.

2. Manufacturers can provide professional product consultation and selection suggestions based on customers' specific needs and application scenarios to help customers choose suitable AS 1111.2 fully threaded hexagon head bolts.

3. Provide customized production.

4. Quality assurance and testing. The manufacturer will ensure that the bolts produced meet the requirements of the AS 1111.2 standard and provide corresponding quality certification documents. Bolts undergo strict quality inspection and testing before leaving the factory to ensure that their quality and performance meet specified requirements.

5. If customers encounter any problems or require technical support during use, the manufacturer will respond promptly and provide solutions.

FAQ

1. What exactly is the AS 1111.2 standard?

Answer: AS 1111.2 is an Australian standard that specifies specific dimensions, tolerances, materials and performance requirements for fully threaded hex head bolts. The bolts we produce comply with this standard, ensuring quality and reliability.

2. Why choose full thread design?

Answer: A fully threaded design means that the entire length of the bolt is threaded, which increases the contact area with the nut or other connecting parts, thereby improving the stability and load-bearing capacity of the connection. Additionally, the fully threaded design reduces the risk of loosening due to thread play.

3. What is the anti-corrosion performance of bolts?

Answer: The bolts we produce usually have good anti-corrosion properties, and their corrosion resistance can be improved through surface treatments such as galvanizing and painting. For special environments, we can also provide stainless steel bolts to meet higher anti-corrosion requirements.

4. How to install and use bolts correctly?

Answer: When installing and using bolts, make sure the bolts and nuts or connectors match, and follow correct installation steps and torque requirements. We can provide installation guides and technical support to ensure customers can install and use bolts correctly.

5. What to do if there is a problem with the bolt?

Answer: If customers find problems with the bolts during use, we will provide timely after-sales service. Customers can contact our customer service team, and we will provide solutions based on specific circumstances, including returns, repairs, or reshipments.