ASME B18.2.1-3 Heavy Hexagon Head Bolts

Product: ASME B18.2.1-3 Heavy Hexagon Head Bolts

Property Class:4.6,4.8,5.6,5.8,8.8,10.9,12.9,

A2-70, A4-70,A4-80

Finish:Zinc Plating(Yellow Zinc, Zinc Blue, Rinse Color), Black, Phosphate & Oil, Zinc Phosphate, Hot-dip Galvanized(HDG),Dacromet, Geomet

Material:Steel,Stainless Steel

Export country: USA, Japan, Australia, Europe and so on

Support customer customization

The main difference between ASME B18.2.1-3 heavy-duty hex head bolts and regular hex head bolts is their design and purpose. ASME B18.2.1-3 is a heavy-duty hex head bolt standard established by the American Society of Mechanical Engineers (ASME). Designed to withstand greater tension and shear forces, this type of bolt typically has higher strength and thicker threads. The dimensions of its head and shaft have been carefully calculated to ensure that it maintains its structural and functional integrity when subjected to heavy loads. Heavy-duty hexagonal head bolts are mainly used in heavy machinery, building structures and bridges where large loads and vibrations are required. Due to its high strength and durability, it ensures the stability and safety of these structures.

Pictures

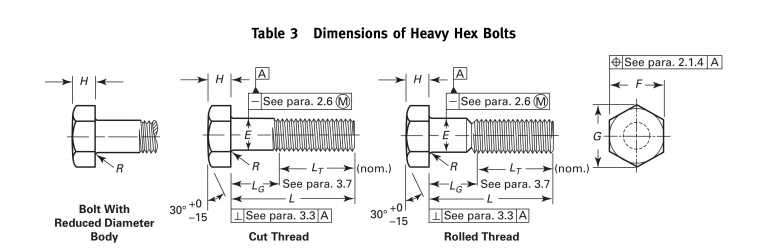

Product drawing

Product Specification

Size | 3/8 | 1/2 | 5/8 | 3/4 | 7/8 | 1 | 1-1/8 | 1-1/4 | 1-3/8 | 1-1/2 | 1-5/8 | 1-3/4 | 1-7/8 | 2 | 2-1/4 | 2-1/2 | 2-3/4 | 3 | |

E | max | 0.388 | 0.515 | 0.642 | 0.768 | 0.895 | 1.022 | 1.149 | 1.277 | 1.404 | 1.531 | 1.658 | 1.785 | 1.912 | 2.039 | 2.305 | 2.559 | 2.827 | 3.081 |

min | 0.360 | 0.482 | 0.605 | 0.729 | 0.852 | 0.976 | 1.098 | 1.223 | 1.345 | 1.470 | 1.591 | 1.716 | 1.839 | 1.964 | 2.214 | 2.461 | 2.711 | 2.961 | |

F | Basic | 11/16 | 7/8 | 1-1/16 | 1-1/4 | 1-7/16 | 1-5/8 | 1-13/16 | 2 | 2-3/16 | 2-3/8 | 2-9/16 | 2-3/4 | 2-15/16 | 3-1/8 | 3-1/2 | 3-7/8 | 4-1/4 | 4-5/8 |

max | 0.688 | 0.875 | 1.062 | 1.250 | 1.438 | 1.625 | 1.812 | 2.000 | 2.188 | 2.375 | 2.562 | 2.750 | 2.938 | 3.125 | 3.500 | 3.875 | 4.250 | 4.625 | |

min | 0.669 | 0.850 | 1.031 | 1.212 | 1.394 | 1.575 | 1.756 | 1.938 | 2.119 | 2.300 | 2.481 | 2.662 | 2.844 | 3.025 | 3.388 | 3.750 | 4.112 | 4.475 | |

G | max | 0.794 | 1.010 | 1.227 | 1.443 | 1.660 | 1.876 | 2.093 | 2.309 | 2.526 | 2.742 | 2.959 | 3.175 | 3.392 | 3.608 | 4.041 | 4.474 | 4.907 | 5.340 |

min | 0.763 | 0.969 | 1.175 | 1.383 | 1.589 | 1.796 | 2.002 | 2.209 | 2.416 | 2.622 | 2.829 | 3.035 | 3.242 | 3.449 | 3.862 | 4.275 | 4.688 | 5.102 | |

H | Basic | 1/4 | 11/32 | 27/64 | 1/2 | 37/64 | 43/64 | 3/4 | 27/32 | 29/32 | 1 | 1-3/32 | 1-5/32 | 1-1/4 | 1-11/32 | 1-1/2 | 1-21/32 | 1-13/16 | 2 |

max | 0.268 | 0.364 | 0.444 | 0.524 | 0.604 | 0.700 | 0.780 | 0.876 | 0.940 | 1.036 | 1.116 | 1.196 | 1.276 | 1.388 | 1.548 | 1.708 | 1.869 | 2.060 | |

min | 0.226 | 0.302 | 0.378 | 0.455 | 0.531 | 0.591 | 0.658 | 0.749 | 0.810 | 0.902 | 0.978 | 1.054 | 1.130 | 1.175 | 1.327 | 1.479 | 1.632 | 1.815 | |

R | max | 0.03 | 0.06 | 0.09 | 0.12 | 0.19 | |||||||||||||

min | 0.01 | 0.02 | 0.03 | 0.04 | 0.06 | ||||||||||||||

Lt | max | 1.000 | 1.250 | 1.500 | 1.750 | 2.000 | 2.250 | 2.750 | 3.000 | 3.250 | 3.500 | 3.750 | 4.000 | 4.250 | 4.750 | 5.250 | 5.750 | 6.250 | |

min | 1.250 | 1.500 | 1.750 | 2.000 | 2.250 | 2.500 | 2.750 | 3.000 | 3.250 | 3.500 | 3.750 | 4.000 | 4.250 | 4.500 | 5.000 | 5.500 | 6.000 | 6.500 | |

Support customer customization | |||||||||||||||||||

Some introduction about our company

Application

Our products are widely used in mechanical, electrical, automotive, building construction, railways, bridges, steamships, fire protection and communication system, etc.

Workshop

Certification

Through scientific management, Jinan Star Fastener Co., Ltd. has obtained the 2015 version of ISO9001 quality management system certification. In 2017, the laboratory passed the national CNAS certification. In 2018, the company passed the European CE certification.

Testing Equipment

Our company has a specialized laboratory with digital hardness testers, microscopes, universal testing machines, axial force meters, hydrogen embrittlement detection devices, magnetic particle flaw detectors, metallographic analyzers, carbon and sulfur analyzers and salt spray testing machines, etc. Experimental testing equipment is used to conduct comprehensive testing of the chemical composition of raw materials, product hardness, mechanical properties, coating thickness and corrosion resistance to ensure that all products meet standard requirements and satisfy customers.

Production equipment

Our company has more than 300 production equipment.The product production process includes: Annealing, shot blasting, cold heading, thread rolling, heat treatment, galvanizing, finished product testing, packaging, etc. are all completed in the company.

Packing

Service

Jinan manufacturers are committed to providing customers with high-quality ASME B18.2.1-3 heavy-duty hexagon head bolt products and providing a series of service support. Our services include but are not limited to product consultation, customized production, quality testing, logistics and distribution, and after-sales technical support. Jinan Star has a professional technical team, advanced production equipment and excellent after-sales service team to ensure that the products comply with ASME B18.2.1-3 standards so that customers can get satisfactory bolt products.

FAQ

1.What is the difference between ASME B18.2.1-3 heavy-duty hexagon head bolts and ordinary hexagon head bolts?

Answer: Compared with ordinary hexagon head bolts, ASME B18.2.1-3 heavy-duty hexagon head bolts pay more attention to strength and durability in design. They typically have thicker threads and larger heads to withstand greater tensile and shear forces. These bolts are suitable for applications such as heavy machinery, building structures and bridges that need to withstand large loads and vibrations.

2. How to choose the appropriate ASME B18.2.1-3 heavy-duty hex head bolt?

Answer: Selecting the appropriate ASME B18.2.1-3 heavy-duty hexagonal head bolt requires consideration of multiple factors, including the material of the connection, thickness, hole diameter, and the load and vibration required to withstand it. We recommend that you select appropriate bolt specifications and performance levels based on specific application scenarios and needs. Our technical team can provide you with professional advice and support.

3. How does your manufacturer ensure the quality of ASME B18.2.1-3 heavy-duty hex head bolts?

Answer: We produce ASME B18.2.1-3 heavy-duty hexagon head bolts in strict accordance with ASME B18.2.1-3 standards and conduct strict quality control and testing. We use advanced production equipment and technology to ensure that the dimensions, tolerances, materials and performance of our products meet standard requirements. In addition, we also provide quality certification documents and inspection reports for customers' reference and verification.

4. Questions about logistics distribution and after-sales service?

Answer: We provide fast and reliable logistics and distribution services to ensure that you can receive products in time. At the same time, we have a complete after-sales service system. If you encounter any problems or need technical support during use, our professional team will provide you with help and support at any time.