AS 2451 BSW Threaded Hexagon Head Bolts

Product: AS 2451 BSW Threaded Hexagon Head Bolts

Property Class: Gr307A, 307B, 325, A449, A490 2,5,8

Finish:Zinc Plating(Yellow Zinc, Zinc Blue,Rinse Color), Black, Phosphate & Oil, Zinc Phosphate, Hot-dip Galvanized(HDG),Dacromet, Geomet

Material:Steel,Stainless

Export country: USA, Japan, Australia, Europe and so on

Support customer customization

Pictures

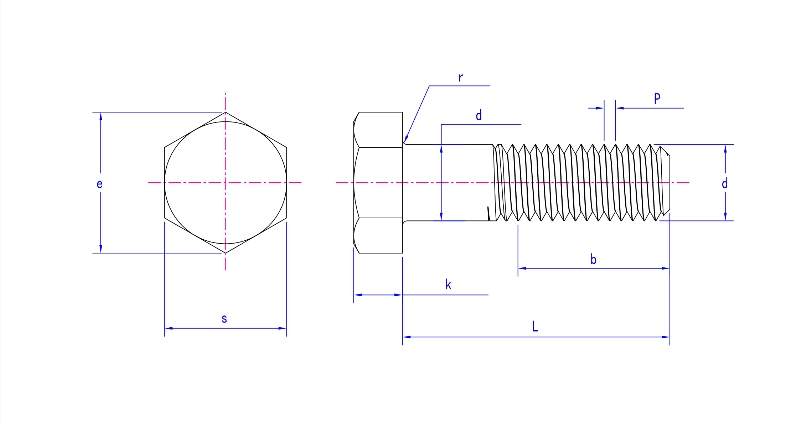

Product drawing

Product Specification

Size | 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | 9/16 | 5/8 | 3/4 | 7/8 | 1 | 1-1/8 | 1-1/4 | 1-3/8 | 1-1/2 | 1-5/8 | 1-3/4 | 1-7/8 | 2 | |

P | 20 | 18 | 16 | 14 | 12 | 12|18|24 | 11 | 10 | 9 | 8 | 7 | 6 | 5 | 6 | 4.5 | ||||

ds max | 0.28 | 0.342 | 0.405 | 0.468 | 0.53 | 0.5625 | 0.665 | 0.79 | 0.915 | 1.04 | 1.175 | 1.3 | 1.425 | 1.55 | 1.685 | 1.81 | 1.875 | 2.06 | |

k | max | 0.186 | 0.228 | 0.27 | 0.312 | 0.363 | 0.371 | 0.447 | 0.53 | 0.623 | 0.706 | 0.79 | 0.89 | 0.98 | 1.06 | 1.18 | 1.27 | 1.198 | 1.43 |

min | 0.166 | 0.208 | 0.25 | 0.292 | 0.333 | 0.348 | 0.417 | 0.5 | 0.583 | 0.666 | 0.75 | 0.83 | 0.92 | 1.0 | 1.08 | 1.17 | 1.114 | 1.33 | |

s | max | 0.445 | 0.525 | 0.60 | 0.71 | 0.82 | 0.812 | 1.01 | 1.2 | 1.3 | 1.48 | 1.67 | 1.86 | 2.05 | 2.22 | 2.41 | 2.58 | 2.812 | 2.76 |

min | 0.435 | 0.515 | 0.585 | 0.695 | 0.8 | 0.798 | 0.985 | 1.175 | 1.27 | 1.45 | 1.64 | 1.815 | 2.005 | 2.175 | 2.365 | 2.52 | 2.719 | 2.7 | |

r min | 1/32 | 0.938 | 3/64 | 1/16 | 1/8 | ||||||||||||||

e min | 0.51 | 0.619 | 0.69 | 0.82 | 0.95 | 0.91 | 1.12 | 1.34 | 1.45 | 1.65 | 1.87 | 2.07 | 2.29 | 2.48 | 2.7 | 2.87 | 3.099 | 3.08 | |

Support customer customization | |||||||||||||||||||

Some introduction about our company

Application

Our products are widely used in mechanical, electrical, automotive, building construction, railways, bridges, steamships, fire protection and communication system, etc.

Workshop

Certification

Through scientific management, Jinan Star Fastener Co., Ltd. has obtained the 2015 version of ISO9001 quality management system certification. In 2017, the laboratory passed the national CNAS certification. In 2018, the company passed the European CE certification.

Testing Equipment

Our company has a specialized laboratory with digital hardness testers, microscopes, universal testing machines, axial force meters, hydrogen embrittlement detection devices, magnetic particle flaw detectors, metallographic analyzers, carbon and sulfur analyzers and salt spray testing machines, etc. Experimental testing equipment is used to conduct comprehensive testing of the chemical composition of raw materials, product hardness, mechanical properties, coating thickness and corrosion resistance to ensure that all products meet standard requirements and satisfy customers.

Production equipment

Our company has more than 300 production equipment.The product production process includes: Annealing, shot blasting, cold heading, thread rolling, heat treatment, galvanizing, finished product testing, packaging, etc. are all completed in the company.

Packing

FAQ

1. What is AS 2451 Whitworth thread?

Answer: AS 2451 is an Australian standard that specifies technical requirements and test methods for bolts and other threaded fasteners. Whitworth thread (BSW) is an early British standard thread type, also known as Whitworth thread. It has a specific profile angle and pitch for specific applications.

2. Why choose Whitworth thread?

Answer: Whitworth threads have been widely used historically, especially in some older equipment or specific industries. While modern thread standards such as ISO or DIN may be more advanced in some aspects, Whitworth threads still have their unique advantages in certain specific applications.

3. What are the specifications of bolts?

Answer: Bolt specifications include diameter, length, pitch and other parameters. Specific specifications depend on application requirements, but can generally be found in the AS 2451 standard.

4. How to install and use bolts?

Answer: When installing and using bolts, you need to ensure that the bolts match the nuts or other connecting parts and follow the correct installation steps and torque requirements. During the installation process, you also need to pay attention to keeping the bolts and connections clean to avoid impurities and dirt from affecting the connection performance.

5. What is the anti-corrosion performance of bolts?

Answer: The anti-corrosion performance of bolts depends on their material and surface treatment. For stainless steel bolts, they themselves have good corrosion resistance; for carbon steel bolts, their anti-corrosion properties can be improved through surface treatments such as galvanizing and painting. The specific processing method to choose needs to be decided based on the application environment and requirements.