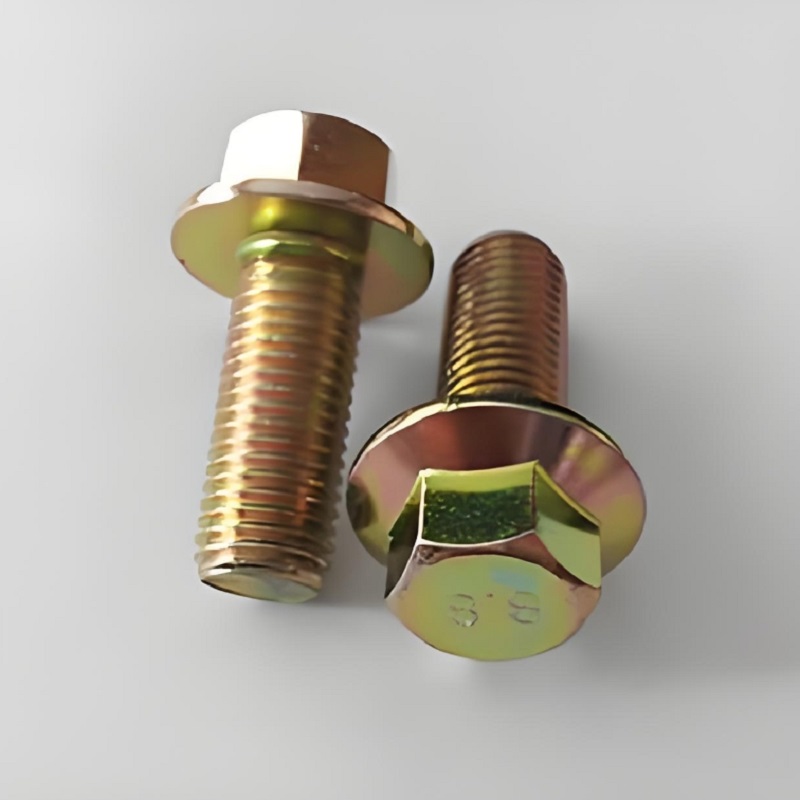

High Strength Flange Bolts

1.IFI 538 Heavy Hex Flange Bolts

2.Source bolt manufacturer, own factory: with price advantage, eliminating the price difference of middlemen.

3.Adopt the industry's top high-quality thickened steel, high stability and long-lasting durability.

4.Support customer customization.

5.Professional sales and after-sales service, welcome to inquire at any time.

6.Delivery on time.

The Ultimate Guide to High Strength Flange Bolts

In modern engineering and heavy-duty construction, securing structural integrity is non-negotiable. High Strength Flange Bolts play a vital role in ensuring that machinery, vehicles, and infrastructure hold up under extreme stress. This article explores everything you need to know about High Strength Flange Bolts, including their design, materials, advantages, applications, and why they’re a preferred fastener in demanding environments.

What Are High Strength Flange Bolts?

High Strength Flange Bolts are robust threaded fasteners with an integrated washer-like flange under the bolt head. This flange distributes pressure over a larger surface area, reducing the risk of damage to the connected parts. What sets these bolts apart is their material composition and heat treatment process, which results in higher tensile and yield strength compared to standard bolts.

Key Advantages of High Strength Flange Bolts

1. Superior Load-Bearing Capacity

Designed for high-stress applications, High Strength Flange Bolts offer exceptional load-bearing capacity. Their ability to withstand shear and tensile forces makes them suitable for critical joints in structural assemblies.

2. Integrated Flange for Better Pressure Distribution

The flange under the bolt head acts as a built-in washer, minimizing the risk of surface deformation. This feature also enhances the bolt's grip and prevents loosening due to vibrations.

3. Vibration Resistance

Thanks to the increased friction surface provided by the flange, High Strength Flange Bolts offer better vibration resistance than traditional hex bolts, especially in dynamic environments such as engines or rotating machinery.

4. Time-Saving Installation

Because there's no need for a separate washer, High Strength Flange Bolts speed up the assembly process. This improves productivity in mass production and field installations.

Applications of High Strength Flange Bolts

High Strength Flange Bolts are commonly used across multiple industries due to their unmatched reliability:

Automotive: Engine blocks, chassis frames, suspension systems

Construction: Steel structures, bridge supports, seismic reinforcement

Heavy Machinery: Mining equipment, cranes, press machines

Oil & Gas: Pipeline flanges, pressure vessels, offshore rigs

Railway & Aerospace: Fastening joints requiring consistent performance under shock and load

Material and Grade Specifications

To meet demanding industry standards, High Strength Flange Bolts are manufactured using premium materials such as:

Alloy Steel (Grade 10.9 / 12.9): For extreme tensile strength

Carbon Steel with Heat Treatment: Cost-effective but still durable

Stainless Steel (A2-70 / A4-80): Excellent for corrosion resistance

These bolts often meet international standards like:

Surface Treatments for Corrosion Resistance

To further enhance durability, High Strength Flange Bolts are treated with various coatings:

Zinc Plating: Basic corrosion resistance

Hot-Dip Galvanizing: Ideal for outdoor applications

Black Oxide: Improves aesthetic and minimal corrosion resistance

Phosphate Coating: Enhances lubricity for easier installation

Installation Best Practices

To ensure maximum performance, keep these tips in mind when installing High Strength Flange Bolts:

Use a calibrated torque wrench to avoid over-tightening.

Ensure surfaces are clean and free from oils or dirt.

Use matching nuts with equivalent strength grade.

Always follow manufacturer torque specifications.

Comparison with Standard Bolts

| Feature | High Strength Flange Bolts | Standard Hex Bolts |

|---|---|---|

| Tensile Strength | Very High | Moderate |

| Integrated Flange | Yes | No |

| Vibration Resistance | Excellent | Average |

| Assembly Speed | Fast | Slower |

| Application Environments | Heavy-duty | General purpose |

Why Choose High Strength Flange Bolts?

If your application requires superior performance, longevity, and safety, High Strength Flange Bolts are the logical choice. From reducing downtime due to fastener failure to enhancing structural integrity, these bolts are a proven solution across global industries.

Their integrated design reduces the number of components required, while their material composition ensures they stand up to the toughest conditions. Whether you’re working on a high-performance engine or a massive steel bridge, High Strength Flange Bolts offer unmatched security.

Conclusion

Choosing the right fastener is crucial for the safety and efficiency of your project. High Strength Flange Bolts not only meet but exceed expectations in strength, durability, and ease of installation. By understanding their properties and applications, engineers and technicians can ensure every joint performs optimally under pressure.

For superior fastening performance, look no further than High Strength Flange Bolts—engineered to hold tight when it matters most.

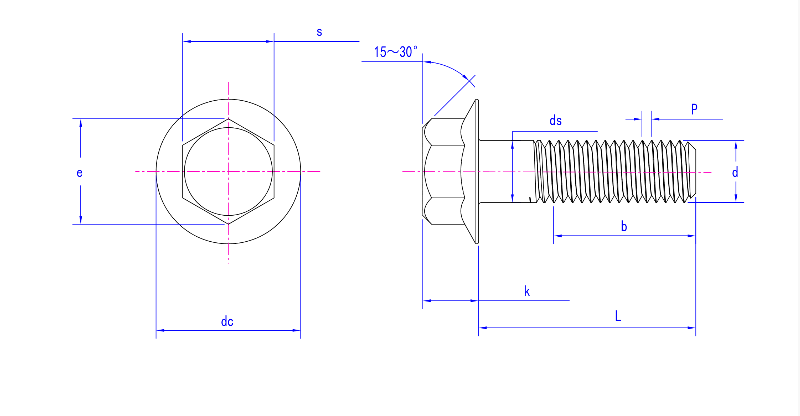

Product drawing