JIS B1189 Hexagon Head Head Flange Bolts

Product: JIS B1189 Hexagon Head Head Flange Bolts

Property Class:4.6,4.8,5.6,5.8,8.8,10.9,12.9,

A2-70, A4-70,A4-80

Finish:Zinc Plating(Yellow Zinc, Zinc Blue, Rinse Color), Black, Phosphate & Oil, Zinc Phosphate, Hot-dip Galvanized(HDG),Dacromet, Geomet

Material:Steel

Export country: USA, Japan, Australia, Europe and so on

Support customer customization

In the world of mechanical engineering and construction, the importance of reliable fasteners cannot be overstated. The JIS B1189 Hexagon Head Flange Bolts are engineered to meet stringent Japanese Industrial Standards, offering superior strength, durability, and ease of installation. Whether you are working on automotive assembly, machinery, or structural frameworks, these bolts ensure secure and efficient fastening.

This article covers everything you need to know about JIS B1189 Hexagon Head Flange Bolts, including specifications, applications, advantages, and selection tips.

What Are JIS B1189 Hexagon Head Flange Bolts?

The JIS B1189 Hexagon Head Flange Bolts conform to the Japanese Industrial Standard B1189, which specifies the dimensions, mechanical properties, and quality requirements for hexagon head flange bolts. These bolts feature a hexagonal head with an integrated flange that acts as a washer, distributing the load and reducing the need for separate washers during assembly.

The flange design provides improved bearing surface and helps prevent loosening due to vibration, making JIS B1189 Hexagon Head Flange Bolts a preferred choice in various industrial sectors.

Key Features of JIS B1189 Hexagon Head Flange Bolts

1. Standardized Dimensions and Quality

Manufactured according to JIS B1189 standards, these hexagon head flange bolts have consistent dimensions and threading. This standardization guarantees interchangeability and reliability in engineering projects.

2. Integrated Flange for Load Distribution

The built-in flange on the bolt head evenly spreads the clamping force, protecting the connected materials from damage. This eliminates the need for separate washers, simplifying installation.

3. High Strength and Corrosion Resistance

Made from high-grade alloy steel or stainless steel, JIS B1189 Hexagon Head Flange Bolts provide excellent tensile strength and corrosion resistance. This makes them suitable for harsh environments and critical applications.

4. Vibration Resistance

The flange design enhances resistance to loosening caused by vibration and dynamic loads, ensuring secure connections over time.

Applications of JIS B1189 Hexagon Head Flange Bolts

The versatility of JIS B1189 Hexagon Head Flange Bolts makes them widely used in:

Automotive manufacturing and assembly

Machinery and equipment fastening

Structural steelwork

Electronics enclosures

Heavy-duty industrial projects

Their reliability under mechanical stress and vibration makes them indispensable in these sectors.

How to Choose the Right JIS B1189 Hexagon Head Flange Bolts

When selecting JIS B1189 Hexagon Head Flange Bolts, consider the following:

Material Grade: Choose stainless steel for corrosion resistance or alloy steel for high strength.

Size and Thread Pitch: Match the bolt size and thread to your application requirements according to JIS B1189 specifications.

Coating: Zinc-plated or galvanized finishes improve corrosion protection.

Load Requirements: Ensure the bolt’s tensile strength meets your project’s demands.

Conclusion

The JIS B1189 Hexagon Head Flange Bolts provide a reliable, standardized fastening solution for industries requiring strength, durability, and efficiency. Their integrated flange design simplifies installation and improves load distribution, making them an ideal choice for automotive, industrial, and structural applications.

Choosing the right JIS B1189 Hexagon Head Flange Bolts ensures long-lasting and secure connections that meet Japan’s rigorous industrial standards.

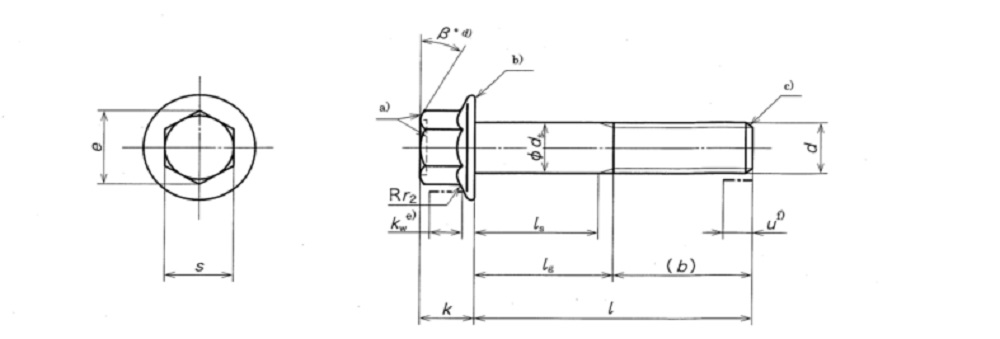

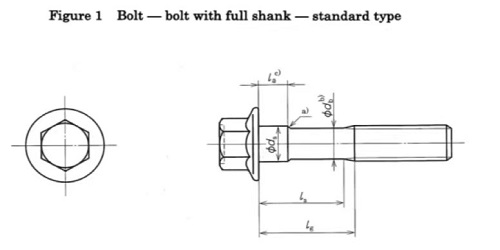

Product drawing

Product Specification

Size | M5 | M6 | M8 | M10 | M12 | M14 | M16 | |

P | 0.8 | 1.0 | 1.25 | 1.5 | 1.75 | 2.0 | 2.0 | |

b | c | 16 | 18 | 22 | 26 | 30 | 34 | 38 |

d | / | / | 28 | 32 | 36 | 40 | 44 | |

e | / | / | / | / | / | / | 57 | |

c min | 1.0 | 1.1 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | |

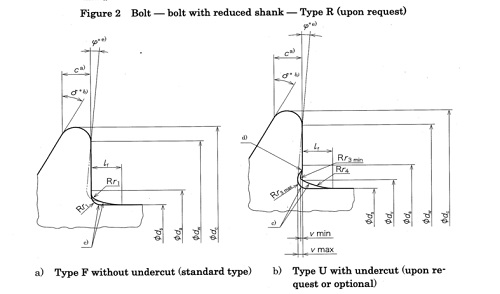

da max | type F | 5.7 | 6.8 | 9.2 | 11.2 | 13.7 | 15.7 | 17.7 |

type U | 6.2 | 7.5 | 10.0 | 12.5 | 15.2 | 17.7 | 20.5 | |

dc max | 11.4 | 13.6 | 17.0 | 20.8 | 24.7 | 28.6 | 32.8 | |

ds | max | 5.0 | 6.0 | 8.0 | 10.0 | 12.0 | 14.0 | 16.0 |

min | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | |

dv max | 5.5 | 6.6 | 8.8 | 10.8 | 12.8 | 14.8 | 17.2 | |

dw min | 9.4 | 11.6 | 14.9 | 18.7 | 22.5 | 26.4 | 30.6 | |

e min | 7.59 | 8.71 | 10.95 | 14.26 | 16.5 | 19.86 | 23.15 | |

k max | 5.6 | 6.9 | 8.5 | 9.7 | 12.1 | 12.9 | 15.2 | |

kw min | 2.3 | 2.9 | 3.8 | 4.3 | 5.4 | 5.6 | 6.8 | |

lf max | 1.4 | 1.6 | 2.1 | 2.1 | 2.1 | 2.1 | 3.2 | |

r1 min | 0.2 | 0.25 | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | |

r2 max | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.9 | 1.0 | |

r3 | max | 0.25 | 0.26 | 0.36 | 0.45 | 0.54 | 0.63 | 0.72 |

min | 0.1 | 0.11 | 0.16 | 0.20 | 0.24 | 0.28 | 0.32 | |

r4 | 4.0 | 4.4 | 5.7 | 5.7 | 5.7 | 5.7 | 8.8 | |

s | max | 7.0 | 8.0 | 10.0 | 13.0 | 15.0 | 18.0 | 21.0 |

min | 6.78 | 7.78 | 9.78 | 12.73 | 14.73 | 17.73 | 20.67 | |

v | max | 0.15 | 0.2 | 0.25 | 0.3 | 0.35 | 0.45 | 0.5 |

min | 0.05 | 0.05 | 0.1 | 0.15 | 0.15 | 0.2 | 0.25 | |

Support customer customization | ||||||||