Hex Head Screw ISO 4017

1.ISO 4017 Hexagon Head Bolts

2.Own a factory. Eliminate the price difference of middlemen and enjoy price advantage.

3.Adopt top-quality thickened steel in the industry, ensuring high stability and long-lasting durability.

4.Support customer customization.

5. Provide professional sales and after-sales service. Welcome to inquire at any time.

6. Deliver on time.

Hex Head Screw ISO 4017: Precision Fastening with International Standards

The hex head screw ISO 4017 is a widely used mechanical fastener designed for high-performance industrial, automotive, and construction applications. Manufactured according to ISO 4017 specifications, this screw features a hexagonal head and fully threaded shank, ensuring consistent quality, reliable load distribution, and easy installation.

Whether you’re assembling steel structures or mounting heavy-duty equipment, the hex head screw ISO 4017 delivers superior performance in environments that demand strength, accuracy, and corrosion resistance.

What Is a Hex Head Screw ISO 4017?

A hex head screw ISO 4017 is a fully threaded hexagon head bolt standardized under the International Organization for Standardization (ISO). These screws are:

Fully threaded along the shank

Equipped with a hexagonal head for easy tool access

Manufactured with precision tolerances for consistent fit

Available in metric sizes ranging from M5 to M64

Compliant with ISO 4017, equivalent to DIN 933 and EN 24017

The hex head screw ISO 4017 ensures compatibility with global engineering and manufacturing systems, making it ideal for international projects.

Key Features of Hex Head Screw ISO 4017

Standardized Design

The hex head screw ISO 4017 conforms to strict dimensional standards, ensuring interchangeability and engineering consistency worldwide.High Tensile Strength

Made from carbon steel, alloy steel, or stainless steel, hex head screw ISO 4017 is built for demanding load-bearing applications.Corrosion Protection

Available with zinc plating, hot-dip galvanizing, or black oxide finish, the hex head screw ISO 4017 resists corrosion in harsh environments.Versatile Use

The hex head screw ISO 4017 is ideal for steel fabrication, machinery assembly, automotive systems, and more.Easy Installation

The hexagonal head allows for high torque application with standard wrenches or sockets, making the hex head screw ISO 4017 user-friendly.

Common Applications of Hex Head Screw ISO 4017

Mechanical engineering

Construction and infrastructure

Automotive and heavy vehicles

Industrial machinery

Steel structure connections

Power plants and energy systems

The hex head screw ISO 4017 is trusted for securing critical joints and high-stress points in structural and mechanical assemblies.

Material Options for Hex Head Screw ISO 4017

Grade 8.8, 10.9, 12.9 carbon steel for high strength

A2-70 / A4-80 stainless steel for corrosion resistance

Surface finishes: Plain, zinc-plated, hot-dip galvanized, black oxide

Each hex head screw ISO 4017 is tailored to meet environmental and mechanical demands based on your application needs.

Conclusion

The hex head screw ISO 4017 is a reliable, high-precision fastener that complies with global standards. Its strength, versatility, and full-threaded design make it essential for a wide range of industries. When your project demands consistent quality and dependable fastening, the hex head screw ISO 4017 is the perfect solution.

Pictures

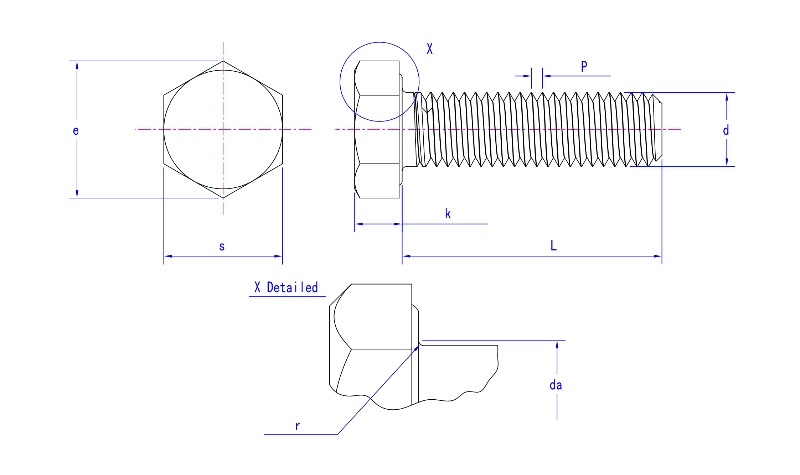

Product drawing

Product Specification

Size | M1.6 | M2 | M2.5 | M3 | M3.5 | M4 | M5 | M6 | M7 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | M33 | M36 | M39 | M42 | M45 | M48 | M52 | M56 | M60 | M64 | |

P | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | 1.0 | 1.25 | 1.5 | 1.75 | 2.0 | 2.0 | 2.5 | 2.5 | 2.5 | 3.0 | 3.0 | 3.5 | 3.5 | 4.0 | 4.0 | 4.5 | 4.5 | 5.0 | 5.0 | 5.5 | 5.5 | 6.0 | |

da max | 2.0 | 2.6 | 3.1 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 7.8 | 9.2 | 12.2 | 13.7 | 15.7 | 17.7 | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | 48.6 | 52.6 | 56.6 | 63.0 | 67.0 | 71.0 | |

e min | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 17.77 | 20.03 | 23.36 | 26.75 | 30.14 | 33.53 | 37.72 | 39.98 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | 76.95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 | |

k | max | 1.225 | 1.525 | 1.825 | 2.125 | 2.525 | 2.925 | 3.65 | 4.15 | 4.95 | 5.45 | 6.58 | 7.68 | 8.98 | 10.18 | 11.715 | 12.715 | 14.215 | 15.215 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | 28.42 | 30.42 | 33.5 | 35.5 | 38.5 | 40.5 |

min | 0.975 | 1.275 | 1.575 | 1.875 | 2.275 | 2.675 | 3.35 | 3.85 | 4.65 | 5.15 | 6.22 | 7.32 | 8.62 | 9.82 | 11.285 | 12.285 | 13.785 | 14.785 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | 27.58 | 29.58 | 32.5 | 34.5 | 37.5 | 39.5 | |

r min | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.2 | 1.2 | 1.6 | 1.6 | 2.0 | 2.0 | 2.0 | |

s | max | 3.2 | 4.0 | 5.0 | 5.5 | 6.0 | 7.0 | 8.0 | 10.0 | 11.0 | 13.0 | 16.0 | 18.0 | 21.0 | 24.0 | 27.0 | 30.0 | 34.0 | 36.00 | 41.0 | 46.0 | 50.0 | 55.0 | 60.0 | 65.0 | 70.0 | 75.0 | 80.0 | 85.0 | 90.0 | 95.0 |

min | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 15.73 | 17.73 | 20.67 | 23.67 | 26.67 | 29.67 | 33.38 | 35.38 | 40.0 | 45.0 | 49.0 | 53.8 | 58.8 | 63.1 | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 | |

Support customer customization | |||||||||||||||||||||||||||||||