Double Ended Screws

1.DIN 938 Double-ended Bolts bm=1d

2.Source bolt manufacturer, own factory: with price advantage, eliminating the price difference of middlemen.

3.Adopt the industry's top high-quality thickened steel, high stability and long-lasting durability.

4.Support customer customization.

5.Professional sales and after-sales service, welcome to inquire at any time.

6.Delivery on time.

Double Ended Screws: Versatile Fasteners for Multiple Applications

Double Ended Screws are one of the most versatile and commonly used fasteners in various industries. These screws are designed with threads on both ends, making them ideal for applications where a secure fastening is required on both sides of a workpiece. Their unique design allows them to be used in a wide range of industries, from construction to machinery assembly, offering both strength and flexibility.

Pictures

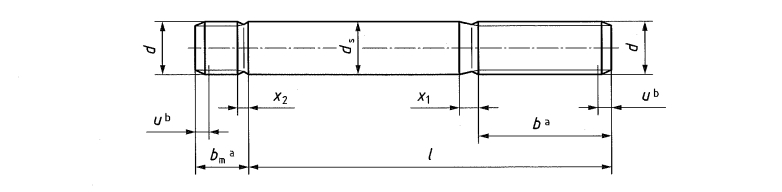

Product drawing

Key Features of Double Ended Screws

Threading on Both Ends

The defining feature of Double Ended Screws is their dual threading. With threads on both ends, these screws can be inserted into materials from both directions. This feature allows for secure fastening from either side, providing greater flexibility in assembly.Variety of Lengths and Diameters

Double Ended Screws come in a wide range of lengths and diameters, allowing them to be used in a variety of applications. Whether you need a small screw for delicate work or a longer screw for heavy-duty use, you can find a suitable option for your needs.Corrosion-Resistant Materials

To ensure long-lasting performance in various environments, Double Ended Screws are often made from corrosion-resistant materials like stainless steel, carbon steel, or alloy steel. These materials enhance the durability of the screws, making them suitable for both indoor and outdoor use.Customizable Design Options

Double Ended Screws are available in different thread patterns, lengths, and finishes to meet specific application requirements. Customization options ensure that these screws can be tailored to suit particular installation needs.

Advantages of Double Ended Screws

Enhanced Strength and Durability

The dual threads of Double Ended Screws provide superior holding power, making them highly effective in applications that require strong and durable connections. Whether you are working with metal, wood, or plastic, these screws are designed to create a tight, long-lasting fit.Versatility Across Industries

Double Ended Screws are used in a wide array of industries, including construction, automotive, electronics, and furniture manufacturing. Their ability to securely fasten materials together from both ends makes them an ideal choice for diverse applications.Efficient Installation Process

These screws make installation faster and more efficient. Because they can be inserted from both ends, there is no need to use additional fasteners, simplifying the assembly process. This can save both time and labor costs, especially in large-scale projects.Cost-Effective Solution

By providing secure fastening and reducing the need for multiple fasteners, Double Ended Screws are a cost-effective solution. Their durability and long-lasting performance also mean fewer replacements, resulting in long-term savings.

Applications of Double Ended Screws

Furniture Assembly

Double Ended Screws are commonly used in the furniture industry, where they help to secure pieces together in a compact and stable manner. The dual threading allows for easier and stronger connections between components, ensuring that furniture pieces remain firmly in place.Automotive Industry

In automotive manufacturing, Double Ended Screws are often used to secure parts and components within engines and chassis. The robust design of these screws ensures that critical parts stay in place even under high stress and vibration.Construction and Structural Applications

For construction projects, Double Ended Screws are used to attach beams, framing, and other structural elements. Their ability to provide a secure and reliable fastening from both sides is essential in ensuring the integrity and strength of the structure.Electrical and Electronics

Double Ended Screws are also commonly found in the electronics industry, where they are used to secure electrical components within devices and enclosures. Their precision threading ensures a tight fit and prevents parts from loosening over time.

Why Choose Double Ended Screws?

Improved Load Distribution

The dual threading of Double Ended Screws allows for more even distribution of load across the fastened material. This is crucial in preventing material failure and ensuring the long-term durability of the assembly.Dual Connection Points

The ability to fasten from both ends makes Double Ended Screws a highly flexible solution for projects where access to only one side may be limited. This dual connection point increases the versatility of these screws in a wide range of applications.Strong, Reliable Performance

Double Ended Screws are designed to offer strong, reliable performance. Their thread design and high-quality materials ensure that the fasteners will withstand the test of time and maintain their integrity in demanding environments.Wide Range of Material Compatibility

Whether you are working with wood, metal, plastic, or composite materials, Double Ended Screws are compatible with a variety of surfaces. Their thread design and material properties ensure a secure fit in multiple applications, from light-duty to heavy-duty use.

Conclusion: Why Opt for Double Ended Screws?

When looking for a fastener that combines versatility, strength, and durability, Double Ended Screws are the perfect solution. Their unique dual-thread design ensures secure connections from both ends, making them ideal for a variety of applications across multiple industries. Whether you're assembling furniture, building structures, or working on automotive projects, Double Ended Screws offer the performance and reliability you need. Choose Double Ended Screws for your next project and experience the benefits of strong, secure fastening.