ASME B18.9 Head Plow Bolts

Product: ASME B18.9 Head Plow Bolts

Property Class: Gr307A, 307B, 325, A449, A490 2,5,8

Finish:Zinc Plating(Yellow Zinc, Zinc Blue,Rinse Color), Black, Phosphate & Oil, Zinc Phosphate, Hot-dip Galvanized(HDG),Dacromet, Geomet

Material:Steel

Export country: USA, Japan, Australia, Europe and so on

Support customer customization

ASME B18.9 Head Plow Bolts: Heavy-Duty Fastening for Agricultural and Industrial Applications

When it comes to ensuring secure, durable fastening in agricultural and industrial environments, ASME B18.9 Head Plow Bolts offer exceptional performance. Manufactured in accordance with the ASME B18.9 standard, these bolts are essential for machinery and equipment that require robust, high-strength connections, particularly in farming, construction, and heavy equipment industries.

What Are ASME B18.9 Head Plow Bolts?

ASME B18.9 Head Plow Bolts are a specialized type of bolt designed to fasten plowshares, cutting edges, and other components of agricultural or construction equipment. Compliant with the ASME B18.9 specification, these bolts feature a unique head design, typically a square or hexagonal shape, that provides a secure grip when tightened with the corresponding tools.

The ASME B18.9 standard governs the dimensions, materials, and mechanical properties of the bolts to ensure consistency and reliability across industries.

Key Features of ASME B18.9 Head Plow Bolts

Choosing ASME B18.9 Head Plow Bolts ensures a range of beneficial features:

Durable Construction: Made from high-strength carbon steel or alloy steel for maximum durability under heavy mechanical stress.

Specialized Head Design: The large, flat head design offers superior surface contact for secure tightening, particularly for plowshares and heavy-duty equipment.

High Tensile Strength: These bolts are designed to resist shearing and vibration, making them ideal for high-stress applications.

Standard Compliance: Manufactured according to the ASME B18.9 standard, ensuring high quality and performance consistency.

Corrosion-Resistant Coatings: Available in finishes like zinc-plated, black oxide, or hot-dip galvanized for added resistance to rust and corrosion in harsh environments.

Variety of Sizes: Offered in a wide range of diameters and lengths to fit various agricultural and industrial equipment.

With these robust characteristics, ASME B18.9 Head Plow Bolts deliver reliable fastening for demanding tasks, ensuring smooth operation and reduced downtime.

Benefits of Using ASME B18.9 Head Plow Bolts

The decision to use ASME B18.9 Head Plow Bolts provides numerous advantages for engineers, manufacturers, and operators in agricultural and heavy equipment sectors:

Enhanced Durability: Resistant to wear, vibration, and extreme mechanical stress, making them suitable for continuous use in heavy-duty environments.

Easier Installation: The unique head design allows for easy tightening and loosening with hand tools, reducing labor time and costs.

Corrosion Resistance: Various coatings ensure that bolts withstand exposure to moisture, chemicals, and outdoor conditions, extending the lifespan of equipment.

Uniformity and Quality: Manufactured to strict ASME B18.9 standards, these bolts ensure reliable performance and consistent quality across the board.

Versatility: Perfect for agricultural machinery such as plows, tillers, and cultivators, as well as construction and industrial equipment that require durable fastening solutions.

For any equipment subjected to tough operating conditions, ASME B18.9 Head Plow Bolts provide long-term, dependable performance.

Common Applications of ASME B18.9 Head Plow Bolts

ASME B18.9 Head Plow Bolts are used across various industries, particularly in agricultural, construction, and heavy equipment sectors:

Agricultural Equipment: Used in plows, cultivators, and other farming machinery to secure the cutting edge or other essential components.

Construction Machinery: Fastening components in bulldozers, backhoes, and graders that encounter high mechanical stress.

Heavy Equipment: Ideal for securing parts in cranes, excavators, and loaders, where strength and stability are paramount.

Mining and Quarrying: Securing wear parts in mining machinery and transport equipment.

Road Construction: Fastening plow blades, graders, and snow removal equipment, ensuring safe and efficient operation.

Wherever durability, strength, and ease of maintenance are required, ASME B18.9 Head Plow Bolts are the ideal fastening solution.

How to Select the Right ASME B18.9 Head Plow Bolts

Choosing the correct ASME B18.9 Head Plow Bolts involves several important factors:

Material Type: Select the appropriate material for your application. Carbon steel is standard for most uses, while alloy steel may be necessary for extreme conditions.

Bolt Size: Ensure the correct bolt diameter and length for proper fitment in your equipment. Sizes vary from smaller bolts for light-duty use to larger, heavy-duty options for industrial machinery.

Thread Type: Coarse or fine threading may be needed depending on the material being fastened and the load requirements.

Finish: Choose the right coating to protect the bolt from corrosion and wear, particularly for outdoor applications or those exposed to harsh conditions.

Strength Rating: Consider the load capacity and tensile strength of the bolt to ensure it meets the mechanical demands of your machinery.

Properly selecting ASME B18.9 Head Plow Bolts ensures optimal performance and prevents costly maintenance or downtime.

Installation Tips for ASME B18.9 Head Plow Bolts

To achieve maximum efficiency and longevity with ASME B18.9 Head Plow Bolts, follow these installation best practices:

Use the Correct Tool: Use the appropriate wrench or socket for the square or hex head design to avoid damaging the bolt.

Torque Settings: Apply the correct torque as specified for the bolt and equipment to prevent over-tightening or under-tightening.

Use Washers: When necessary, install washers under the bolt head to distribute the load and prevent surface damage.

Lubrication: Use anti-seize lubrication on threads to prevent rusting and ensure smooth removal during future maintenance.

Regular Inspection: Periodically check bolts for signs of wear or loosening, especially in machinery subjected to high vibrations or harsh conditions.

Proper installation will maximize the performance and lifespan of ASME B18.9 Head Plow Bolts.

Why Choose ASME B18.9 Head Plow Bolts?

Choosing ASME B18.9 Head Plow Bolts is a smart decision for anyone in need of strong, reliable, and standardized fastening solutions for heavy-duty applications. With their exceptional durability, corrosion resistance, and ease of use, these bolts deliver long-term performance for agricultural, construction, and industrial machinery.

For operators and manufacturers looking for a durable, high-strength fastening solution, ASME B18.9 Head Plow Bolts are the ideal choice.

Conclusion

ASME B18.9 Head Plow Bolts are indispensable fasteners for agricultural, industrial, and construction applications. Manufactured to rigorous standards, these bolts provide the strength, reliability, and corrosion resistance required for heavy-duty machinery. Whether you’re securing a plowshare or fastening components in a grader or excavator, ASME B18.9 Head Plow Bolts offer unmatched performance and durability.

Invest in quality and longevity with ASME B18.9 Head Plow Bolts, and ensure the smooth operation of your equipment for years to come.

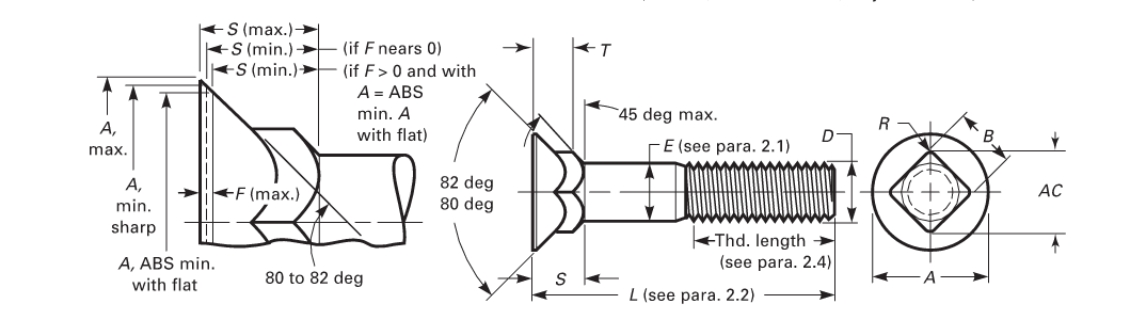

Product drawing