Fine Thread Stainless Steel Screws

1.ISO 8676 Hexagon Head Screws with Fine Pitch Thread

2.Own a factory. Eliminate the price difference of middlemen and enjoy price advantage.

3.Adopt top-quality thickened steel in the industry, ensuring high stability and long-lasting durability.

4.Support customer customization.

5. Provide professional sales and after-sales service. Welcome to inquire at any time.

6. Deliver on time.

Fine Thread Stainless Steel Screws: Precision Fastening with Superior Corrosion Resistance

Fine thread stainless steel screws are precision-engineered fasteners designed for applications that demand high tensile strength, vibration resistance, and long-term durability in corrosive environments. With a tighter thread pitch than standard coarse screws, fine thread stainless steel screws offer enhanced load distribution, greater holding power, and improved alignment during assembly.

Whether used in aerospace, automotive, machinery, or marine environments, fine thread stainless steel screws deliver reliable performance where accuracy and corrosion resistance are critical.

What Are Fine Thread Stainless Steel Screws?

Fine thread stainless steel screws feature a smaller distance between threads, known as thread pitch, compared to coarse thread variants. This design provides more threads per unit length, allowing for stronger engagement with the material and better resistance to loosening under stress or vibration.

Key features of fine thread stainless steel screws include:

Fine Thread Pitch: Ideal for precise, high-strength fastening.

Corrosion-Resistant Stainless Steel: Suitable for harsh or wet environments.

Smooth Surface Finish: Prevents galling and ensures consistent tightening.

Versatile Head Styles: Available in pan head, flat head, hex head, and more.

The combination of fine threading and stainless steel construction makes fine thread stainless steel screws a top choice for high-performance assemblies.

Advantages of Fine Thread Stainless Steel Screws

Increased Tensile Strength

With more threads in contact, fine thread stainless steel screws can handle greater axial loads compared to coarse-thread screws.Superior Vibration Resistance

The tighter thread spacing reduces the risk of loosening under constant movement or vibration, making fine thread stainless steel screws ideal for machinery and automotive components.Corrosion Protection

Made from high-grade stainless steel (such as 304 or 316), fine thread stainless steel screws resist rust, oxidation, and chemical corrosion in demanding environments.Precision Alignment

Fine threads allow for incremental tightening and better alignment during installation, especially important in tight tolerance applications.Cleaner, More Secure Fit

The increased number of threads per inch creates a smoother threading experience and a tighter fit, helping ensure stability in structural assemblies.

Applications of Fine Thread Stainless Steel Screws

Fine thread stainless steel screws are used in a wide range of industries and applications, such as:

Automotive and Aerospace: Engine components, chassis, and structural parts.

Marine and Offshore: Boat hardware, rigging, and underwater equipment.

Precision Machinery: Equipment requiring fine adjustments and high strength.

Electronics and Instruments: For secure assembly with minimal vibration.

Medical Equipment: Clean, rust-resistant fasteners in sterile environments.

Stainless Steel Fabrication: Joining panels, brackets, and structural elements.

The performance benefits of fine thread stainless steel screws make them essential for high-specification engineering and construction tasks.

Choosing the Right Fine Thread Stainless Steel Screws

To select the best fine thread stainless steel screws for your project, consider:

Material Grade: 304 for general use; 316 for superior corrosion resistance.

Thread Size and Pitch: Match to the application for optimal holding strength.

Head Style: Flat, pan, button, hex, or socket heads based on tool access and finish.

Drive Type: Phillips, slotted, Torx, or hex depending on torque and convenience.

Length and Shank Diameter: Choose based on material thickness and design requirements.

Proper selection ensures fine thread stainless steel screws perform flawlessly in structural, mechanical, or decorative roles.

Conclusion

Fine thread stainless steel screws offer a perfect combination of strength, precision, and corrosion resistance. Their tight threading provides better grip, load-bearing capacity, and vibration resistance, while stainless steel ensures lasting durability in challenging environments. For projects that demand accuracy and reliability, fine thread stainless steel screws are the ideal fastening solution.

Pictures

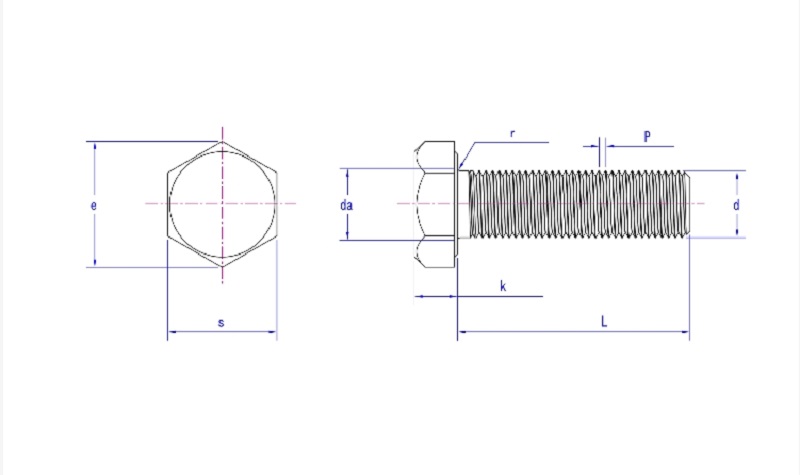

Product drawing

Product Specification

Size | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | M33 | M36 | M39 | M42 | M45 | M48 | M52 | M56 | M60 | M64 | |

P | 1.0 | 1|1.25 | 1.25|1.5 | 1.5 | 1.5 | 1.5 | 1.5|2 | 1.5 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 3.0 | 3.0 | 3.0 | 3.0 | 4.0 | 4.0 | 4.0 | |

r min | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.2 | 1.2 | 1.6 | 1.6 | 2.0 | 2.0 | 2.0 | |

da max | 9.2 | 11.2 | 13.7 | 15.7 | 17.7 | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | 48.6 | 52.6 | 56.6 | 63.0 | 67.0 | 71.0 | |

k | max | 5.45 | 6.58 | 7.68 | 8.98 | 10.18 | 11.715 | 12.715 | 14.215 | 15.215 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | 28.42 | 30.42 | 33.5 | 35.5 | 38.5 | 40.5 |

min | 5.15 | 6.22 | 7.32 | 8.62 | 9.82 | 11.285 | 12.285 | 13.785 | 14.785 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | 27.58 | 29.58 | 32.5 | 34.5 | 37.5 | 39.5 | |

s | max | 13.0 | 16.0 | 18.0 | 21.0 | 24.0 | 27.0 | 30.0 | 34.0 | 36.00 | 41.0 | 46.0 | 50.0 | 55.0 | 60.0 | 65.0 | 70.0 | 75.0 | 80.0 | 85.0 | 90.0 | 95.0 |

min | 12.73 | 15.73 | 17.73 | 20.67 | 23.67 | 26.67 | 29.67 | 33.38 | 35.38 | 40.0 | 45.0 | 49.0 | 53.8 | 58.8 | 63.1 | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 | |

e min | 14.38 | 17.77 | 20.03 | 23.36 | 26.75 | 30.14 | 33.53 | 37.72 | 39.98 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | 76.95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 | |

Support customer customization | ||||||||||||||||||||||