Plow Bolt

1.ASME B18.9 No.3 Head Plow Bolts

2.Source bolt manufacturer, own factory: with price advantage, eliminating the price difference of middlemen.

3.Adopt the industry's top high-quality thickened steel, high stability and long-lasting durability.

4.Support customer customization.

5.Professional sales and after-sales service, welcome to inquire at any time.

6.Delivery on time.

Plow Bolt: The Essential Fastening Solution for Agricultural and Industrial Equipment

Plow bolts are a type of heavy-duty fastener specifically designed for use in agricultural, industrial, and construction equipment. With their robust construction and unique design, plow bolts are essential for securing components in environments that demand high strength and reliability. The unique design features a square neck under the head, which prevents the bolt from turning once it is installed, making it particularly ideal for applications where high torque and vibration resistance are needed.

Pictures

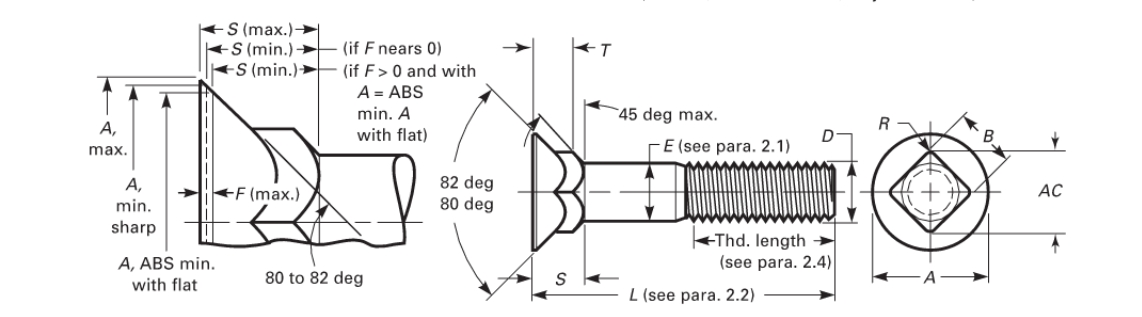

Product drawing

Key Features of Plow Bolts

Square Neck Design

One of the defining features of plow bolts is the square neck under the head, which helps prevent rotation during installation and ensures the bolt remains securely in place. This feature is particularly beneficial in machinery and equipment where constant vibration and heavy forces are common. The square neck design eliminates the need for a washer, providing a more efficient and secure fastening solution.Durable and High-Strength Material

Plow bolts are typically manufactured from high-strength steel, including carbon steel or alloy steel, to provide superior durability and load-bearing capacity. These materials are resistant to wear, rust, and corrosion, making plow bolts suitable for use in harsh environments, such as agricultural fields and construction sites.Wide Range of Applications

Plow bolts are versatile and can be used in various applications, from agricultural machinery, such as plows, cultivators, and harrows, to heavy-duty construction equipment like bulldozers, excavators, and cranes. Their ability to withstand high stress and pressure makes them indispensable in industries that require reliable fastening solutions for large, heavy-duty equipment.Easy Installation

The square neck design of the plow bolt ensures that it remains stable during installation, providing ease of use for workers in the field or workshop. These bolts can be installed with standard wrenches or impact tools, which reduces the time required for assembly and maintenance.

Advantages of Plow Bolts

Enhanced Torque Resistance

Plow bolts are designed to handle significant amounts of torque without turning or loosening. This feature is critical in environments where the bolt will be subjected to high rotational forces, such as when fastening blades on agricultural equipment or securing heavy components on construction machinery.Prevents Loosening Under Vibration

In high-vibration environments, bolts often experience loosening, leading to maintenance issues and costly downtime. The unique square neck of the plow bolt locks it securely in place, preventing any movement or loosening, even under the harshest operating conditions. This provides added peace of mind, ensuring that your equipment remains securely fastened at all times.Long-Lasting Performance

Plow bolts are manufactured to last, with high resistance to wear, corrosion, and mechanical stress. This durability translates to reduced maintenance and fewer replacements over the lifespan of the equipment. The strong and reliable nature of plow bolts helps to keep machinery and tools functioning efficiently for years.Corrosion Resistance

Many plow bolts come with corrosion-resistant coatings such as zinc plating or hot-dip galvanization, making them ideal for outdoor applications where they are exposed to moisture, dirt, and harsh weather conditions. This protective coating enhances their longevity, preventing rust and degradation that can affect other types of fasteners.

Applications of Plow Bolts

Agricultural Machinery

Plow bolts are most commonly used in agricultural equipment, where they secure parts such as blades, coulters, and teeth on plows, tillers, and other machinery. Their ability to withstand constant stress and provide a secure, tight connection makes them perfect for the demanding conditions of farming and land cultivation.Construction Equipment

In construction, plow bolts are used to secure heavy-duty components such as cutting edges, buckets, and teeth on equipment like bulldozers, graders, and excavators. These fasteners play a crucial role in ensuring that the components remain in place during operation, even when exposed to heavy forces and rough terrain.Mining and Heavy Industry

Mining and heavy industries require equipment that can endure extreme wear and pressure. Plow bolts are used in various types of machinery in these sectors, including crushers, conveyor systems, and material handling equipment. Their ability to resist wear and provide a strong, stable connection under harsh operating conditions is vital for the success of these industries.Landscaping Equipment

Landscaping machinery, such as mowers, trenchers, and seeders, also relies on plow bolts to secure critical components like blades and attachments. In this field, the ability of the plow bolt to resist loosening from vibration and constant movement ensures the long-term reliability of the equipment.Railway Maintenance

Plow bolts are also used in railway track maintenance, where they secure track components to the railbed. The strength and durability of plow bolts ensure that the fasteners can handle the constant vibration and stress from passing trains, preventing track displacement and ensuring safe rail operations.

Why Choose Plow Bolts?

Reliable Performance in Harsh Conditions

Whether it’s agricultural machinery, construction equipment, or heavy industrial machines, plow bolts provide dependable performance in harsh environments. Their resistance to wear, corrosion, and vibration makes them the go-to solution for industries that require high-performance fasteners.Cost-Effective Solution

With their long lifespan and minimal maintenance requirements, plow bolts offer a cost-effective fastening solution. Their ability to stay in place without loosening or wearing out means fewer replacements, less downtime, and ultimately, lower operational costs for businesses.Versatile and Customizable

Plow bolts come in a range of sizes, lengths, and materials to suit specific needs. Whether you need a bolt for a small piece of equipment or a larger, high-capacity machine, plow bolts can be customized to meet the demands of your project, ensuring optimal performance.Enhanced Safety

The secure, tight-fitting design of plow bolts helps reduce the risk of equipment failure, ensuring safer operation. The reduced chance of components loosening under stress or vibration leads to fewer accidents and increased overall safety in the workplace.

Conclusion: Why Plow Bolts Are an Indispensable Fastener

In conclusion, plow bolts are an essential fastener used across various industries, including agriculture, construction, and heavy industry. With their unique square neck design, robust material strength, and superior resistance to vibration and wear, plow bolts provide a reliable and durable solution for securing components under high stress. Whether you're looking to fasten agricultural blades, construction equipment parts, or mining machinery, plow bolts are the optimal choice for ensuring secure, long-lasting performance in even the most demanding conditions.

For more information on plow bolts and to find the right fastener for your project, contact us or explore our extensive catalog of high-quality industrial fasteners.