Hex Socket Cap Screw

1.GBT 70.1 Hexagon Socket Head Cap Screws

2.Own a factory. Eliminate the price difference of middlemen and enjoy price advantage.

3.Adopt top-quality thickened steel in the industry, ensuring high stability and long-lasting durability.

4.Support customer customization.

5. Provide professional sales and after-sales service. Welcome to inquire at any time.

6. Deliver on time.

Hex Socket Cap Screw: Durable Fasteners for High-Torque Applications

The hex socket cap screw is a highly versatile fastener designed to provide superior strength and secure connections in a variety of applications. Featuring a cylindrical head with an internal hexagonal drive, the hex socket cap screw is specifically engineered to be tightened using a hex key or Allen wrench, making it ideal for high-torque applications. Its design offers exceptional durability, resistance to loosening, and an aesthetic finish, making it a popular choice in industries such as automotive, aerospace, and industrial machinery.

Whether you are securing heavy machinery, automotive parts, or structural components, the hex socket cap screw ensures a reliable, tight, and secure fastening.

What is a Hex Socket Cap Screw?

A hex socket cap screw is a type of screw characterized by the following features:

Hexagonal Recess: The internal hexagonal drive in the screw head allows for high torque application using an Allen wrench or hex key. This design makes the screw easy to tighten and prevents slippage during installation.

Cylindrical Head: The hex socket cap screw features a cylindrical head that provides a clean, streamlined look and is ideal for applications where the fastener needs to be flush with the surface.

Full Threading: The screw is typically fully threaded, which ensures a strong and secure hold over the entire length of the shaft.

Material Variety: Made from durable materials such as carbon steel, stainless steel, and alloy steel, the hex socket cap screw is capable of withstanding high-stress and high-torque environments.

These fasteners are used in applications where high strength, precision, and reliability are required.

Key Features of Hex Socket Cap Screws

High Torque Resistance

The hex socket cap screw is designed to handle high torque loads without compromising the integrity of the screw or the material being fastened. The hexagonal recess allows for efficient torque application, making it a preferred choice for industrial and mechanical applications.Strong and Secure Connection

The hex socket cap screw offers a secure connection thanks to its full threading, which provides maximum engagement between the screw and the material. This ensures that the fastener stays tightly in place under stress and prevents loosening during vibration or movement.Flush-Mounted Design

The cylindrical head of the hex socket cap screw allows it to sit flush with the surface once tightened. This feature is ideal for applications where a clean and smooth finish is required, reducing the risk of the screw catching or causing interference with surrounding components.Corrosion Resistance

For applications exposed to harsh environments, the hex socket cap screw can be made from corrosion-resistant materials such as stainless steel or treated with coatings like zinc plating. This ensures long-lasting performance even in moisture, chemicals, or extreme temperatures.Versatility Across Industries

The hex socket cap screw is widely used in various industries, including automotive, aerospace, manufacturing, and construction, due to its high strength, ease of installation, and aesthetic appearance.

Common Applications of Hex Socket Cap Screws

Automotive Industry: Hex socket cap screws are essential in automotive assembly, securing engine components, chassis parts, and other high-stress mechanical systems.

Aerospace: The hex socket cap screw is used in the aerospace industry for fastening critical components in aircraft, spacecraft, and related machinery, where strength and precision are vital.

Industrial Machinery: In machinery manufacturing, these screws are used to secure various mechanical parts, motors, and tools that must withstand heavy loads and high torque.

Construction: The hex socket cap screw is used in construction projects for securing structural elements and framing, especially when a secure and flush connection is needed.

Electronics: Due to its flush design and precision, the hex socket cap screw is often used in electronics for mounting sensitive equipment and enclosures.

How to Install Hex Socket Cap Screws

Prepare the Hole

Ensure the hole is properly sized for the hex socket cap screw. The hole should match the diameter and depth of the screw for optimal engagement of the threads.Align the Screw

Insert the hex socket cap screw into the hole, ensuring that the threaded portion is correctly aligned with the material to be fastened.Tighten Using an Allen Wrench

Insert an Allen wrench or hex key into the hexagonal recess of the screw. Tighten the screw by applying controlled, even torque to ensure a secure connection.Check for Tightness

After tightening, check to ensure the screw is fully engaged and that it sits flush with the surface. If necessary, apply additional torque until the screw is securely fastened.

How to Choose the Right Hex Socket Cap Screw

When selecting a hex socket cap screw, consider the following factors:

Material: Choose carbon steel for strength, stainless steel for corrosion resistance, or alloy steel for high-performance applications.

Size and Thread Type: Ensure the screw’s size and thread pitch are appropriate for the application.

Finish: Select the right coating for your environmental needs. Options like zinc plating or black oxide can provide additional protection against corrosion.

Strength: Check the tensile strength of the screw to ensure it can handle the required load and stress for your specific application.

Conclusion

The hex socket cap screw is an essential fastening solution for high-performance applications where strength, precision, and reliability are critical. Its ability to withstand high torque, secure connections, and provide a flush-mounted finish makes it an ideal choice in industries such as automotive, aerospace, and industrial machinery. With its durability, ease of installation, and versatility, the hex socket cap screw continues to be a trusted fastener in various demanding environments.

Pictures

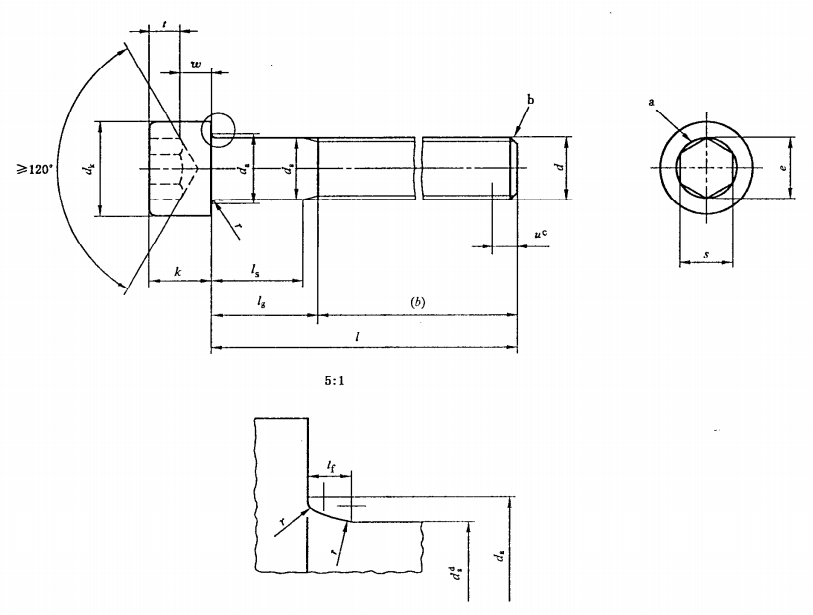

Product drawing

Product Specification

Size | M1.6 | M2 | M2.5 | M3 | M4 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M20 | M24 | M30 | M36 | M42 | M48 | M56 | M64 | ||

P | 0.35 | 0.4 | 0.45 | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 | ||

b | 15 | 16 | 17 | 18 | 20 | 22 | 24 | 28 | 32 | 36 | 40 | 44 | 52 | 60 | 72 | 84 | 96 | 108 | 124 | 140 | ||

dk | Max(c | 3.00 | 3.80 | 4.50 | 5.50 | 7.00 | 8.50 | 10.00 | 13.00 | 16.00 | 18.00 | 21.00 | 24.00 | 30.00 | 36.00 | 45.00 | 54.00 | 63.00 | 72.00 | 84.00 | 96.00 | |

Max(d | 3.14 | 3.98 | 4.68 | 5.68 | 7.22 | 8.72 | 10.22 | 13.27 | 16.27 | 18.27 | 21.33 | 24.33 | 30.33 | 36.39 | 45.39 | 54.46 | 63.46 | 72.46 | 84.54 | 96.54 | ||

min | 2.86 | 3.62 | 4.32 | 5.32 | 6.78 | 8.28 | 9.78 | 12.73 | 15.73 | 17.73 | 20.67 | 23.67 | 29.67 | 35.61 | 44.61 | 53.54 | 62.54 | 71.54 | 83.46 | 95.46 | ||

da max | 2 | 2.6 | 3.1 | 3.6 | 4.7 | 5.7 | 6.8 | 9.2 | 11.2 | 13.7 | 15.7 | 17.7 | 22.4 | 26.4 | 33.4 | 39.4 | 45.6 | 52.6 | 63 | 71 | ||

ds | max | 1.6 | 2.00 | 2.50 | 3.00 | 4.00 | 5.00 | 6.00 | 8.00 | 10.00 | 12.00 | 14.00 | 16.00 | 20.00 | 24.00 | 30.00 | 35.61 | 42.00 | 48.00 | 56.00 | 64.00 | |

min | 1.46 | 1.86 | 2.36 | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 19.67 | 23.67 | 29.67 | 30.854 | 41.61 | 47.61 | 55.54 | 63.54 | ||

e min | 1.733 | 2.303 | 2.873 | 3.443 | 4.583 | 5.723 | 6.683 | 9.149 | 11.429 | 13.716 | 15.996 | 19.437 | 21.734 | 25.154 | 30.854 | 36.571 | 41.131 | 46.831 | 52.531 | |||

L max | 0.34 | 0.51 | 0.51 | 0.51 | 0.6 | 0.6 | 0.68 | 1.02 | 1.02 | 1.45 | 1.45 | 1.45 | 2.04 | 2.04 | 2.89 | 2.89 | 3.06 | 3.91 | 5.95 | 5.95 | ||

k | max | 1.6 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 | 24 | 30 | 36 | 42 | 48 | 56 | 64 | |

min | 1.46 | 1.86 | 2.36 | 2.86 | 3.82 | 4.82 | 5.7 | 7.64 | 9.64 | 11.57 | 13.57 | 15.57 | 19.48 | 23.48 | 29.48 | 35.38 | 41.38 | 47.38 | 55.26 | 63.26 | ||

r min | 0.1 | 0.2 | 0.25 | 0.4 | 0.6 | 0.8 | 1 | 1.2 | 1.6 | 2 | 2 | |||||||||||

s | max | 1.58 | 2.08 | 2.58 | 3.08 | 4.095 | 5.14 | 6.14 | 8.175 | 10.175 | 12.212 | 14.212 | 17.23 | 19.275 | 22.275 | 27.275 | 32.33 | 36.33 | 41.33 | 46.33 | ||

min | 1.52 | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 12.032 | 14.032 | 17.05 | 19.065 | 22.065 | 27.065 | 32.08 | 36.08 | 41.08 | ||||

t min | 0.7 | 1 | 1.1 | 1.3 | 2 | 2.5 | 3 | 4 | 5 | 6 | 7 | 8 | 10 | 12 | 15.5 | 19 | 24 | 28 | 34 | 38 | ||

v max | 0.16 | 0.20 | 0.25 | 0.3 | 0.4 | 0.5 | 0.6 | 0.8 | 1 | 1.2 | 1.4 | 1.6 | 2 | 2.4 | 3 | 3.6 | 4.2 | 4.8 | 5.6 | 6.4 | ||

dw min | 2.72 | 3.48 | 4.18 | 5.07 | 6.53 | 8.03 | 9.38 | 12.33 | 15.33 | 17.23 | 20.17 | 23.17 | 28.87 | 34.81 | 43.61 | 52.54 | 61.34 | 70.34 | 82.26 | 94.26 | ||

w min | 0.55 | 0.55 | 0.85 | 1.15 | 1.4 | 1.9 | 2.3 | 3.3 | 4 | 4.8 | 5.8 | 6.8 | 8.6 | 10.4 | 13.1 | 15.3 | 16.3 | 17.5 | 19 | 22 | ||

Support customer customization | ||||||||||||||||||||||