Socket Countersunk Head Screw

1.GB-T 70.3 Hexagon Socket Countersunk Head Screws with Reduced Loadability

2.Source bolt manufacturer, own factory: with price advantage, eliminating the price difference of middlemen.

3.Adopt the industry's top high-quality thickened steel, high stability and long-lasting durability.

4.Support customer customization.

5.Professional sales and after-sales service, welcome to inquire at any time.

6.Delivery on time.

Socket Countersunk Head Screw: Precision Fasteners for Flush-Mount Applications

The socket countersunk head screw is a highly specialized fastener designed for applications that require a flush, secure, and aesthetically pleasing connection. Featuring a countersunk head and a hexagonal drive, the socket countersunk head screw is tightened using a hex wrench or Allen key, providing a secure and precise fastening. Its design allows it to sit flush with the surface, making it ideal for scenarios where a smooth, streamlined finish is necessary, while still providing exceptional strength and durability.

Whether used in automotive, aerospace, construction, or electronics, the socket countersunk head screw is the ideal solution for high-performance and precision fastening needs.

What is a Socket Countersunk Head Screw?

A socket countersunk head screw is a type of fastener with the following key characteristics:

Countersunk Head: The head of the screw is designed to be tapered so that it sits flush with the surface when tightened. This allows for a smooth and clean finish, eliminating the risk of the screw head protruding from the surface.

Socket Drive: The screw features a hexagonal recess in its head, designed for use with a hex key or Allen wrench. This drive type allows for high torque to be applied, ensuring secure and tight connections.

Threaded Shaft: The screw shaft is typically fully threaded, providing maximum engagement with the material being fastened, which enhances the screw’s holding strength.

Material Variety: Socket countersunk head screws are available in a range of materials such as stainless steel, carbon steel, and alloy steel, making them suitable for a wide range of applications with varying environmental demands.

These fasteners are widely used in applications where both appearance and strength are important.

Key Features of Socket Countersunk Head Screws

Flush-Mounted Design

The socket countersunk head screw is specifically designed to sit flush with the material surface. This makes it an excellent choice for applications where a clean, smooth finish is needed. The countersunk head eliminates the need for a protruding screw, ensuring a neat and professional appearance.High Torque Application

With its hexagonal recess, the socket countersunk head screw allows for the application of high torque using an Allen wrench or hex key. This ensures that the screw can be securely fastened without the risk of slipping, providing a reliable connection.Durability and Strength

Made from high-quality materials such as stainless steel and carbon steel, the socket countersunk head screw is built to withstand heavy loads and high-stress environments. Its ability to resist corrosion, wear, and damage makes it suitable for use in demanding applications.Corrosion Resistance

For applications exposed to moisture, chemicals, or extreme conditions, the socket countersunk head screw can be made from corrosion-resistant materials like stainless steel or treated with protective coatings. This ensures long-lasting performance in harsh environments.Versatility in Applications

The socket countersunk head screw is used across a wide range of industries, including automotive, aerospace, electronics, and construction. Its versatility and robust design make it ideal for both precision and heavy-duty applications.

Common Applications of Socket Countersunk Head Screws

Automotive Industry: The socket countersunk head screw is often used in automotive assemblies, including securing body panels, engine components, and trim where a flush finish is important.

Aerospace: In aerospace, these screws are used to secure lightweight components where both high strength and a smooth finish are required. They help maintain the streamlined appearance and functionality of aircraft and spacecraft.

Construction: The socket countersunk head screw is frequently used in construction for framing, decking, and other applications where a flush, secure fastening is needed.

Electronics: In electronics, these screws are used for mounting circuit boards and securing components inside equipment, where space is limited, and a neat, clean finish is necessary.

Furniture Manufacturing: Socket countersunk head screws are commonly used in furniture assembly, especially for joining parts that need a flush-mounted screw for a sleek and polished look.

How to Install Socket Countersunk Head Screws

Prepare the Hole

Ensure that the hole is properly sized for the socket countersunk head screw. The hole should match the diameter and depth of the screw's countersunk head for it to sit flush with the surface.Align the Screw

Insert the socket countersunk head screw into the hole, ensuring that the threaded portion is properly aligned with the material being fastened.Tighten Using an Allen Wrench

Use a hex wrench or Allen key to tighten the screw. The hexagonal drive allows for high torque application, which ensures the screw is securely fastened without damaging the screw or surrounding material.Check for Flush Fit

Once tightened, check that the socket countersunk head screw sits flush with the surface. If necessary, apply additional torque until the screw is fully engaged and flush.

How to Choose the Right Socket Countersunk Head Screw

When selecting a socket countersunk head screw, consider the following factors:

Material: Choose stainless steel for corrosion resistance, carbon steel for strength, or alloy steel for high-performance applications.

Size and Thread Type: Ensure that the screw’s size and thread type match the specific requirements of your project.

Finish: Depending on the application, select a screw with the appropriate finish, such as zinc plating or black oxide, to enhance durability and corrosion resistance.

Strength and Load Capacity: Check the screw’s tensile strength to ensure it can handle the required load and stress for your specific use.

Conclusion

The socket countersunk head screw is a versatile and durable fastener designed for applications that require a flush, secure connection with high torque resistance. Whether used in automotive, aerospace, construction, or electronics, the socket countersunk head screw offers a reliable and aesthetic solution for high-performance fastening. Its design ensures that the screw sits flush with the surface, providing both strength and a smooth finish. With its corrosion resistance, durability, and versatility, the socket countersunk head screw is an essential component for many demanding industries.

Pictures

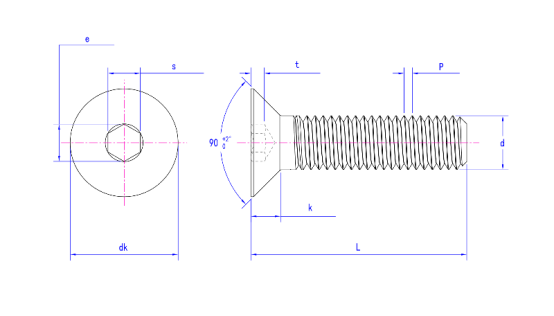

Product drawing

Product Specification

Size | M2 | M2.5 | M3 | M4 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M20 | |

P | 0.4 | 0.45 | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | |

dk | max | 4.70 | 5.88 | 6.72 | 8.96 | 11.21 | 13.44 | 17.92 | 22.4 | 26.88 | 30.8 | 33.6 | 40.32 |

min | 3.70 | 4.80 | 5.54 | 7.53 | 9.43 | 11.34 | 15.24 | 19.22 | 23.12 | 26.52 | 29.01 | 36.05 | |

e min | 1.500 | 1.733 | 2.303 | 2.873 | 3.443 | 4.583 | 5.723 | 6.863 | 9.149 | 11.429 | 11.429 | 13.716 | |

k | max | 1.350 | 1.690 | 1.860 | 2.480 | 3.100 | 3.720 | 4.960 | 6.200 | 7.440 | 8.400 | 8.800 | 10.160 |

min | 1.130 | 1.408 | 1.522 | 2.121 | 2.669 | 3.218 | 4.366 | 5.563 | 6.711 | 7.588 | 7.874 | 9.037 | |

s | max | 1.360 | 1.560 | 2.080 | 2.580 | 3.080 | 4.095 | 5.140 | 6.140 | 8.175 | 10.175 | 10.175 | 12.212 |

min | 1.320 | 1.520 | 2.020 | 2.520 | 3.020 | 4.020 | 5.020 | 6.020 | 8.025 | 10.025 | 10.025 | 12.032 | |

t | max | 0.85 | 1.15 | 1.25 | 1.65 | 2.00 | 2.50 | 3.20 | 3.90 | 4.90 | 5.10 | 5.40 | 6.40 |

min | 0.75 | 1.00 | 1.10 | 1.40 | 1.75 | 2.20 | 2.90 | 3.50 | 4.30 | 4.50 | 4.80 | 5.60 | |

Support customer customization | |||||||||||||