Countersunk Hex Head Screw

1.DIN 7991 Hexagon Socket Countersunk Head Screws

2.Own a factory. Eliminate the price difference of middlemen and enjoy price advantage.

3.Adopt top-quality thickened steel in the industry, ensuring high stability and long-lasting durability.

4.Support customer customization.

5. Provide professional sales and after-sales service. Welcome to inquire at any time.

6. Deliver on time.

Countersunk Hex Head Screw: Precision Fasteners for Flush-Mount Applications

The countersunk hex head screw is a type of fastener designed to provide a secure, flush-mounting connection. Featuring a hexagonal drive for enhanced torque application and a countersunk head that sits flat against the surface, the countersunk hex head screw is ideal for applications where a smooth, clean finish is required. Its ability to sit flush with the material ensures that the screw does not protrude, offering both functional and aesthetic benefits.

Whether you're working in automotive, construction, or manufacturing, the countersunk hex head screw delivers strong, reliable performance, making it a staple in various industries.

What is a Countersunk Hex Head Screw?

A countersunk hex head screw is a screw with the following key features:

Hexagonal Drive: The screw features a hexagonal recess in the head, which allows for the application of higher torque using a standard hex wrench or socket.

Countersunk Head: The head is designed to sit flush with the surface, making it ideal for applications where a smooth finish is required. This design also reduces the risk of snagging or interference with surrounding parts.

Threaded Shaft: The shaft of the screw is fully threaded, ensuring a secure and tight fit that resists loosening under stress.

Material Variety: Made from high-strength materials such as stainless steel, carbon steel, and alloy steel, countersunk hex head screws are suitable for a range of applications that require robust, reliable fastening.

These fasteners are often used in situations where the appearance of the finished product is just as important as the strength of the connection.

Key Features of Countersunk Hex Head Screws

Flush-Mounted Design

The countersunk hex head screw is specifically designed to sit flush with the material it is fastened into. This makes it an excellent choice for applications where a smooth, streamlined surface is necessary.High Torque and Strength

The hexagonal recess allows for precise torque application, ensuring that the screw can be tightened securely without damaging the fastener or surrounding material.Versatility Across Industries

Countersunk hex head screws are used across various industries, including automotive, aerospace, construction, and furniture manufacturing, where both aesthetics and functionality are important.Corrosion Resistance

For applications exposed to harsh environments, countersunk hex head screws can be made from corrosion-resistant materials such as stainless steel or treated with coatings like zinc plating, ensuring durability in outdoor or marine settings.Improved Aesthetic Appeal

The countersunk head creates a clean, flush appearance, which is especially important in visible, high-traffic areas where a smooth finish is desired.

Common Applications of Countersunk Hex Head Screws

Automotive Industry: Countersunk hex head screws are used in automotive assemblies where a smooth finish is required, such as in body panels, doors, and trim.

Construction: In construction, these screws are used for securing components like decking, flooring, and roofing, where a flush, secure connection is crucial.

Furniture Manufacturing: Countersunk hex head screws are commonly used in the assembly of furniture, particularly in cases where the fasteners need to be concealed for a polished look.

Aerospace: The aerospace industry uses countersunk hex head screws for securing lightweight parts and components, where both high strength and a clean finish are important.

Electronics: Ideal for securing electrical panels or circuit boards, the flush design of the countersunk hex head screw ensures that it does not interfere with other components.

How to Install Countersunk Hex Head Screws

Prepare the Hole

Before installation, ensure that the hole is properly sized for the countersunk hex head screw. The hole should be wide enough for the screw’s shaft and deep enough to accommodate the countersunk portion of the screw head.Insert the Screw

Align the countersunk hex head screw with the prepared hole and insert it. Ensure that the head of the screw is flush with the material surface.Tighten with a Hex Wrench

Using a hex wrench or socket, tighten the screw by applying consistent torque. The hexagonal drive allows for easy installation and ensures that the screw is securely fastened.Check for a Flush Fit

Once tightened, ensure that the countersunk hex head screw sits flush with the surface. If necessary, adjust the screw to achieve a smooth, even finish.

How to Choose the Right Countersunk Hex Head Screw

When selecting a countersunk hex head screw, consider the following factors:

Material: Choose from materials like stainless steel for corrosion resistance, carbon steel for strength, or alloy steel for high-performance applications.

Size and Thread Type: Ensure that the screw’s size and thread match the specific requirements of your project.

Finish: Choose the appropriate finish, such as zinc plating, black oxide, or plain, to suit the environmental conditions and appearance preferences of your project.

Length and Head Design: Ensure that the screw’s length is suitable for the material being fastened, and that the countersunk design matches the desired flush finish.

Conclusion

The countersunk hex head screw is an essential fastener for applications that require a flush, secure, and strong connection. Its high torque capabilities, corrosion resistance, and versatile design make it an ideal choice for automotive, construction, aerospace, and other industries. Whether you need a precise, high-strength fastening solution or an aesthetically pleasing, flush design, the countersunk hex head screw provides an optimal solution for your needs.

Pictures

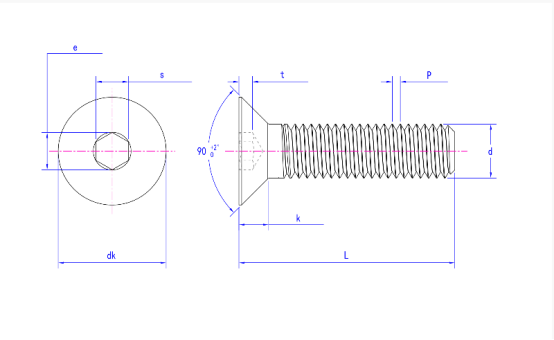

Product drawing

Product Specification

Size | M3 | M4 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | |

P | 0.5 | 0.7 | 0.8 | 1.00 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.50 | 2.50 | 2.5 | 3 | |

dk | max | 6.00 | 8.00 | 10 | 12.00 | 16.00 | 20 | 24 | 27 | 30 | 33 | 36 | 36 | 39 |

min | 5.7 | 7.64 | 9.64 | 11.57 | 15.57 | 19.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 35.38 | 38.38 | |

e min | 2.3 | 2.87 | 3.44 | 4.58 | 5.72 | 6.86 | 9.15 | 11.43 | 11.43 | 13.72 | 16 | 16 | 16 | |

k max | 1.7 | 2.3 | 2.8 | 3.3 | 4.4 | 5.5 | 6.5 | 7.00 | 7.5 | 8.5 | 13.1 | 13.1 | 14 | |

s | min | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 10.025 | 12.032 | 14.032 | 14.032 | 14.032 |

max | 2.1 | 2.60 | 3.1 | 4.12 | 5.14 | 6.14 | 8.175 | 10.175 | 10.175 | 12.121 | 14.212 | 14.212 | 14.212 | |

t | max | 1.2 | 1.8 | 2.3 | 2.5 | 3.5 | 4.4 | 4.6 | 4.8 | 5.3 | 5.5 | 8.8 | 8.8 | 10.3 |

min | 0.95 | 1.55 | 2.05 | 2.25 | 3.2 | 4.1 | 4.3 | 4.5 | 5.00 | 5.2 | 8.44 | 8.44 | 9.87 | |

Support customer customization | ||||||||||||||