JIS B1180 Bolt

1.JIS B1180 Hexagon Head Bolts

2.Own a factory. Eliminate the price difference of middlemen and enjoy price advantage.

3.Adopt top-quality thickened steel in the industry, ensuring high stability and long-lasting durability.

4.Support customer customization.

5. Provide professional sales and after-sales service. Welcome to inquire at any time.

6. Deliver on time.

Understanding the JIS B1180 Bolt: A Comprehensive Guide

The JIS B1180 bolt is a precision-engineered fastener that conforms to the Japanese Industrial Standards (JIS) for hex bolts. Known for its reliability and uniform quality, the JIS B1180 bolt is widely used in automotive, machinery, construction, and heavy equipment industries across Asia and beyond.

What is a JIS B1180 Bolt?

The JIS B1180 bolt is defined by its hexagonal head design, metric threading, and mechanical properties specified under the JIS B1180 standard. This standard ensures that bolts are manufactured to meet consistent dimensions, tolerances, and material requirements. Unlike some other standards, JIS B1180 bolts often feature smaller head dimensions compared to ISO or DIN equivalents, which can be advantageous in compact assembly applications.

Key Features of JIS B1180 Bolt

Material Grades: The JIS B1180 bolt can be produced in various material grades, including carbon steel, alloy steel, and stainless steel, depending on the intended application and required tensile strength.

Thread Type: It typically features a metric coarse or fine thread, designed for easy compatibility with metric nuts and tapped holes.

Surface Treatments: To enhance corrosion resistance, JIS B1180 bolts may be zinc-plated, black oxide-coated, or hot-dip galvanized.

Tensile Strength: The mechanical classification of JIS B1180 bolts usually follows grades like 4.6, 8.8, 10.9, and 12.9, indicating their respective tensile and yield strengths.

Applications of JIS B1180 Bolt

The versatility of the JIS B1180 bolt makes it a preferred choice in:

Automotive assemblies

Agricultural machinery

Industrial manufacturing

Structural steelworks

Marine and offshore structures

Its compatibility with Japanese and Asian equipment is a major reason why the JIS B1180 bolt remains in high demand, especially in regions where Japanese manufacturing standards dominate.

Why Choose JIS B1180 Bolt?

Choosing the JIS B1180 bolt means prioritizing reliability, standardized performance, and international compatibility. These bolts are manufactured under strict quality control, making them suitable for both OEM and aftermarket use. The standardized dimensions also simplify replacement and maintenance processes.

Additionally, the unique head size and threading of the JIS B1180 bolt can offer installation advantages in tight spaces or when working with legacy Japanese machinery.

Pictures

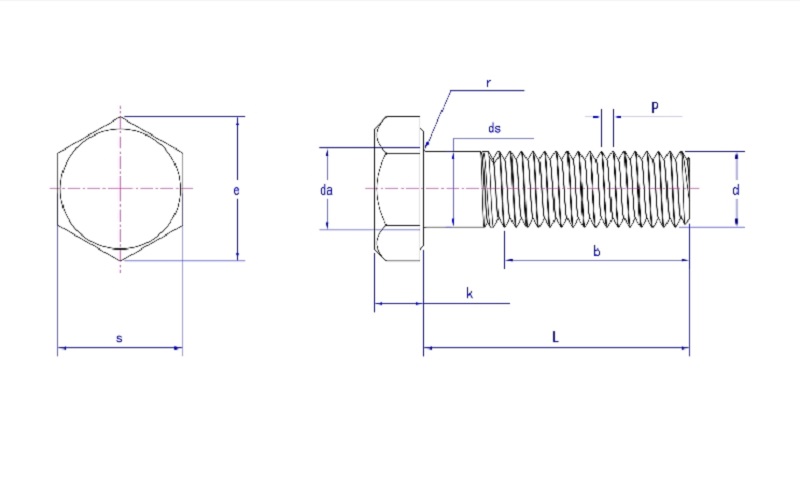

Product drawing

Product Specification

Size | M1.6 | M2 | M2.5 | M3 | M3.5 | M4 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | M33 | M36 | M39 | M42 | M45 | M48 | M52 | M56 | M60 | M64 | |

P | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | 1.25 | 1.5 | 1.75 | 2.0 | 2.0 | 2.5 | 2.5 | 2.5 | 3.0 | 3.0 | 3.5 | 3.5 | 4.0 | 4.0 | 4.5 | 4.5 | 5.0 | 5.0 | 5.5 | 5.5 | 6.0 | |

da max | 2.0 | 2.6 | 3.1 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 9.2 | 11.2 | 13.7 | 15.7 | 17.7 | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | 48.6 | 52.6 | 56.6 | 63.0 | 67.0 | 71.0 | |

ds | max | 1.6 | 2.00 | 2.50 | 3.00 | 3.50 | 4.0 | 5.0 | 6.0 | 8.0 | 10.0 | 12.0 | 14.0 | 16.0 | 18.0 | 20.0 | 22.0 | 24.0 | 27.0 | 30.0 | 33.0 | 36.0 | 39.0 | 42.0 | 45.0 | 48.0 | 52.0 | 56.0 | 60.0 | 64.0 |

min | 1.46 | 1.86 | 2.36 | 2.86 | 3.32 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | 26.48 | 29.48 | 32.38 | 35.38 | 38.38 | 41.38 | 44.38 | 47.38 | 51.26 | 55.26 | 59.26 | 63.26 | |

e min | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 14.38 | 17.77 | 20.03 | 23.36 | 26.75 | 30.14 | 33.53 | 37.72 | 39.98 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | 76.95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 | |

k | max | 1.225 | 1.525 | 1.825 | 2.125 | 2.525 | 2.925 | 3.65 | 4.15 | 5.45 | 6.58 | 7.68 | 8.98 | 10.18 | 11.715 | 12.715 | 14.215 | 15.215 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | 28.42 | 30.42 | 33.5 | 35.5 | 38.5 | 40.5 |

min | 0.975 | 1.275 | 1.575 | 1.875 | 2.275 | 2.675 | 3.35 | 3.85 | 5.15 | 6.22 | 7.32 | 8.62 | 9.82 | 11.285 | 12.285 | 13.785 | 14.785 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | 27.58 | 29.58 | 32.5 | 34.5 | 37.5 | 39.5 | |

r min | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.25 | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.2 | 1.2 | 1.6 | 1.6 | 2.0 | 2.0 | 2.0 | |

s | max | 3.2 | 4.0 | 5.0 | 5.5 | 6.0 | 7.0 | 8.0 | 10.0 | 13.0 | 16.0 | 18.0 | 21.0 | 24.0 | 27.0 | 30.0 | 34.0 | 36.00 | 41.0 | 46.0 | 50.0 | 55.0 | 60.0 | 65.0 | 70.0 | 75.0 | 80.0 | 85.0 | 90.0 | 95.0 |

min | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 12.73 | 15.73 | 17.73 | 20.67 | 23.67 | 26.67 | 29.67 | 33.38 | 35.38 | 40.0 | 45.0 | 49.0 | 53.8 | 58.8 | 63.1 | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 | |

Support customer customization | ||||||||||||||||||||||||||||||