ISO 8676 Hexagon Head Screws with Fine Pitch Thread

Product: ISO 8676 Hexagon Head Screws with Fine Pitch Thread

Property Class:4.6,4.8,5.6,5.8,8.8,10.9,12.9,

A2-70, A4-70,A4-80

Finish:Zinc Plating(Yellow Zinc, Zinc Blue, Rinse Color), Black, Phosphate & Oil, Zinc Phosphate, Hot-dip Galvanized(HDG),Dacromet, Geomet

Material:Steel,Stainless

Export country: USA, Japan, Australia, Europe and so on

Support customer customization

ISO 8676 fine thread hexagonal head screw bolt is a hexagonal head bolt with a specific thread spacing (fine). The fine thread design means the threads of the screw bolt are spaced finer than standard threads. This design provides greater strength and better sealing performance, especially in applications requiring greater precision and tight fit. The head of the ISO 8676 fine thread hexagonal head screw bolt is designed to be hexagonal. The hexagonal head design provides better grip and stability, ensuring that the bolt can be screwed in or out accurately. ISO 8676 fine thread hexagon head screw bolts are widely used in various machinery and equipment, especially where high precision and tight connections are required. ISO 8676 fine thread hexagonal head screws bolts are often used to join metal parts, plastic parts, or other parts that require a strong connection.

Pictures

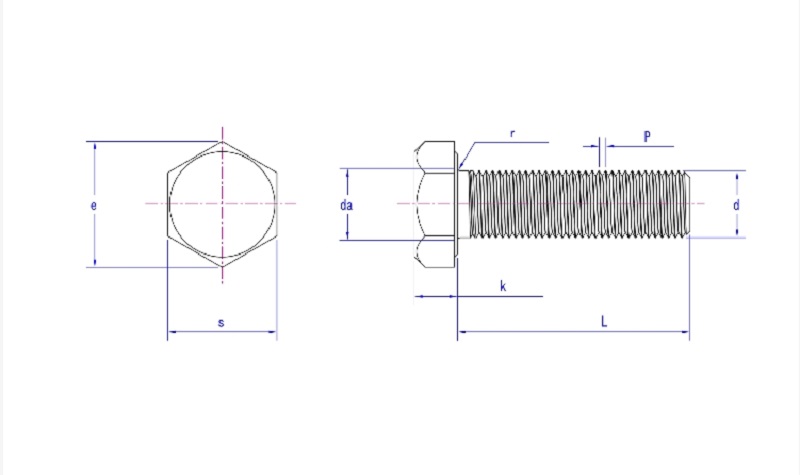

Product drawing

Product Specification

Size | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | M33 | M36 | M39 | M42 | M45 | M48 | M52 | M56 | M60 | M64 | |

P | 1.0 | 1|1.25 | 1.25|1.5 | 1.5 | 1.5 | 1.5 | 1.5|2 | 1.5 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 3.0 | 3.0 | 3.0 | 3.0 | 4.0 | 4.0 | 4.0 | |

r min | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.2 | 1.2 | 1.6 | 1.6 | 2.0 | 2.0 | 2.0 | |

da max | 9.2 | 11.2 | 13.7 | 15.7 | 17.7 | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | 48.6 | 52.6 | 56.6 | 63.0 | 67.0 | 71.0 | |

k | max | 5.45 | 6.58 | 7.68 | 8.98 | 10.18 | 11.715 | 12.715 | 14.215 | 15.215 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | 28.42 | 30.42 | 33.5 | 35.5 | 38.5 | 40.5 |

min | 5.15 | 6.22 | 7.32 | 8.62 | 9.82 | 11.285 | 12.285 | 13.785 | 14.785 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | 27.58 | 29.58 | 32.5 | 34.5 | 37.5 | 39.5 | |

s | max | 13.0 | 16.0 | 18.0 | 21.0 | 24.0 | 27.0 | 30.0 | 34.0 | 36.00 | 41.0 | 46.0 | 50.0 | 55.0 | 60.0 | 65.0 | 70.0 | 75.0 | 80.0 | 85.0 | 90.0 | 95.0 |

min | 12.73 | 15.73 | 17.73 | 20.67 | 23.67 | 26.67 | 29.67 | 33.38 | 35.38 | 40.0 | 45.0 | 49.0 | 53.8 | 58.8 | 63.1 | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 | |

e min | 14.38 | 17.77 | 20.03 | 23.36 | 26.75 | 30.14 | 33.53 | 37.72 | 39.98 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | 76.95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 | |

Support customer customization | ||||||||||||||||||||||

Some introduction about our company

Application

Our products are widely used in mechanical, electrical, automotive, building construction, railways, bridges, steamships, fire protection and communication system, etc.

Workshop

Certification

Through scientific management, Jinan Star Fastener Co., Ltd. has obtained the 2015 version of ISO9001 quality management system certification. In 2017, the laboratory passed the national CNAS certification. In 2018, the company passed the European CE certification.

Testing Equipment

Our company has a specialized laboratory with digital hardness testers, microscopes, universal testing machines, axial force meters, hydrogen embrittlement detection devices, magnetic particle flaw detectors, metallographic analyzers, carbon and sulfur analyzers and salt spray testing machines, etc. Experimental testing equipment is used to conduct comprehensive testing of the chemical composition of raw materials, product hardness, mechanical properties, coating thickness and corrosion resistance to ensure that all products meet standard requirements and satisfy customers.

Production equipment

Our company has more than 300 production equipment.The product production process includes: Annealing, shot blasting, cold heading, thread rolling, heat treatment, galvanizing, finished product testing, packaging, etc. are all completed in the company.

Packing

Service

1. We will provide professional ISO 8676 fine thread hexagon head bolt consultation and selection suggestions based on your needs to ensure that customers choose the appropriate ISO 8676 fine thread hexagon head bolt.

2. If the standard model bolts do not meet your needs, we can provide customized services.

3. Provide ISO 8676 fine thread hexagon head bolt product warranty and after-sales service. If you have any quality problems, you can contact our customer service department to ensure that you have no worries during use.

4. Provide ISO 8676 fine thread hexagon head bolt installation guidance to ensure that you use ISO 8676 fine thread hexagon head bolts correctly and answer problems encountered by customers during installation and use.

FAQ

1.Do ISO 8676 fine thread hexagon head bolts comply with international standards?

Of course, if you need it, we will provide product quality inspection reports and certificates of conformity to ensure that product quality meets ISO 8676 standards and customer requirements.

2.What is the price of ISO 8676 fine thread hexagon head bolts?

We will give you the best price. We will give you a reasonable price based on the material, process, quantity and other factors of the ISO 8676 fine thread hexagon head bolts you need.

3. What should I do if I encounter difficulties during installation and use?

Provide detailed installation guidance and usage instructions to answer problems encountered by customers during installation and use, ensuring that bolts can be installed and used correctly.

4. Do you support customization?

Yes, we support customization. Our sales technicians will introduce you to the process, price and time of customized services in detail, and provide corresponding solutions according to customer requirements.