Hexagon Head Cap Screws

1.ISO 4018 Hexagon Head Screws

2.Own a factory. Eliminate the price difference of middlemen and enjoy price advantage.

3.Adopt top-quality thickened steel in the industry, ensuring high stability and long-lasting durability.

4.Support customer customization.

5. Provide professional sales and after-sales service. Welcome to inquire at any time.

6. Deliver on time.

Hexagon Head Cap Screws: Precision Fastening for High-Strength Applications

Hexagon head cap screws are a critical component in a wide range of mechanical, structural, and industrial applications. Known for their superior tensile strength, reliable grip, and precise fit, hexagon head cap screws are widely used in machinery, automotive, construction, and equipment assembly where durability and secure fastening are essential.

With a hexagonal-shaped head and machine-threaded body, hexagon head cap screws are designed to be installed with a wrench or socket tool, providing excellent torque transfer and minimizing the risk of slippage.

What Are Hexagon Head Cap Screws?

Hexagon head cap screws, often referred to simply as hex head cap screws or hex bolts, feature:

A six-sided head for easy wrench engagement

Fully or partially threaded shafts for various grip and shear requirements

Precise dimensions for accurate alignment and tight fastening

Available in different materials including stainless steel, carbon steel, and alloy steel

Surface treatments such as zinc plating, black oxide, or hot-dip galvanization for corrosion resistance

Whether used in high-load structural systems or fine mechanical assemblies, hexagon head cap screws offer dependable strength and performance.

Key Advantages of Hexagon Head Cap Screws

High Load-Bearing Capacity

Engineered for high-stress environments, hexagon head cap screws provide strong, secure connections that resist shearing and vibration.Ease of Installation

The hex head allows for maximum torque application using standard tools, making hexagon head cap screws easy to install and remove.Versatile Applications

Suitable for everything from heavy-duty construction to precision manufacturing, hexagon head cap screws adapt to both indoor and outdoor environments.Corrosion Resistance

With protective coatings and stainless options, hexagon head cap screws maintain their integrity even in harsh conditions.Customization Options

Available in metric and imperial sizes, various thread types, and custom lengths, hexagon head cap screws meet diverse engineering specifications.

Common Applications of Hexagon Head Cap Screws

Machine assembly

Steel structure fabrication

Automotive components

Construction frameworks

Home improvement and repair

Industrial equipment installation

From fastening engine blocks to connecting metal frames, hexagon head cap screws play a foundational role in keeping systems safe, stable, and efficient.

Choosing the Right Hexagon Head Cap Screws

When selecting hexagon head cap screws, consider the following:

Material requirements (e.g., corrosion resistance, temperature tolerance)

Thread type (coarse vs. fine threads)

Load-bearing capacity

Length and diameter for appropriate grip

Compliance with standards (DIN, ANSI, ISO)

High-quality hexagon head cap screws ensure both mechanical integrity and long-term reliability in your projects.

Conclusion

Whether for industrial use, construction projects, or machinery repair, hexagon head cap screws deliver strength, precision, and versatility. Their durable design and ease of use make them a go-to choice for engineers and builders around the world.

Pictures

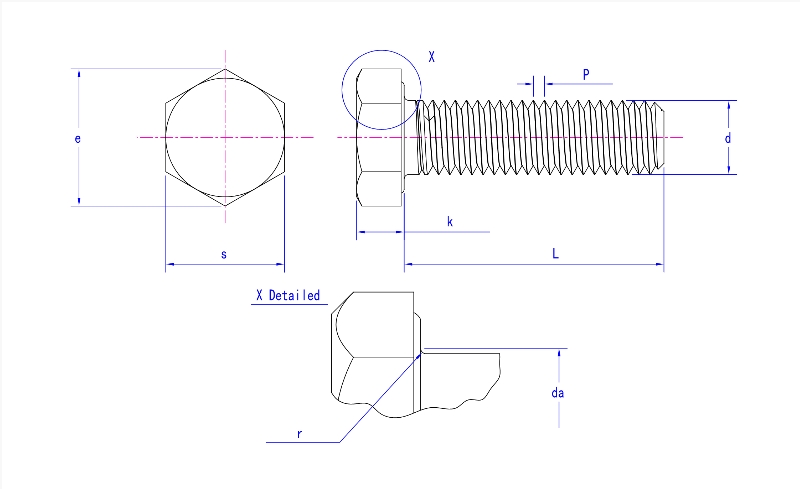

Product drawing

Product Specification

Size | M5 | M6 | M7 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | M33 | M36 | M39 | M42 | M45 | M48 | M52 | M56 | M60 | M64 | |

P | 0.8 | 1.0 | 1.0 | 1.25 | 1.5 | 1.75 | 2.0 | 2.0 | 2.5 | 2.5 | 2.5 | 3.0 | 3.0 | 3.5 | 3.5 | 4.0 | 4.0 | 4.5 | 4.5 | 5.0 | 5.0 | 5.5 | 5.5 | 6.0 | |

da max | 6.0 | 7.2 | 8.2 | 10.2 | 12.2 | 14.7 | 16.7 | 18.7 | 21.2 | 24.4 | 26.4 | 28.4 | 32.4 | 35.4 | 38.4 | 42.4 | 45.4 | 48.6 | 52.6 | 56.6 | 62.6 | 67.0 | 71.0 | 75.0 | |

e min | 8.63 | 10.89 | 11.94 | 14.2 | 17.59 | 19.85 | 22.78 | 26.17 | 29.56 | 32.95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | 76.95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 | |

k | max | 3.875 | 4.375 | 5.175 | 5.675 | 6.85 | 7.95 | 9.25 | 10.75 | 12.4 | 13.4 | 14.9 | 15.9 | 17.9 | 19.75 | 22.05 | 23.55 | 26.05 | 27.05 | 29.05 | 31.05 | 34.25 | 36.25 | 39.25 | 41.25 |

min | 3.125 | 3.625 | 4.425 | 4.925 | 5.95 | 7.05 | 8.35 | 9.25 | 10.6 | 11.6 | 13.1 | 14.1 | 16.1 | 17.65 | 19.95 | 21.45 | 23.95 | 24.95 | 26.95 | 28.95 | 31.75 | 33.75 | 36.75 | 38.75 | |

r min | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.5 | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.2 | 1.2 | 1.6 | 1.6 | 2.0 | 2.0 | 2.0 | |

s | max | 8.0 | 10.0 | 11.0 | 13.0 | 16.00 | 18.00 | 21.0 | 24.0 | 27.0 | 30.0 | 34.0 | 36.0 | 41.0 | 46.0 | 50.0 | 55.0 | 60.0 | 65.0 | 70.0 | 75.0 | 80.0 | 85.0 | 90.0 | 95.0 |

min | 7.64 | 9.64 | 10.57 | 12.57 | 15.57 | 17.57 | 20.16 | 23.16 | 26.16 | 29.16 | 33.0 | 35.0 | 40.0 | 45.0 | 49.0 | 53.8 | 58.8 | 63.1 | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 | |

Support customer customization | |||||||||||||||||||||||||