BSW Bolts

1.BSW Threaded Hexagon Head Bolts AS 2451

2.Source bolt manufacturer, own factory: with price advantage, eliminating the price difference of middlemen.

3.Adopt the industry's top high-quality thickened steel, high stability and long-lasting durability.

4.Support customer customization.

5.Professional sales and after-sales service, welcome to inquire at any time.

6.Delivery on time.

BSW Bolts – An In-Depth Look at Their Features, Benefits, and Applications

BSW bolts (British Standard Whitworth bolts) are a specific type of bolt designed according to the British Standard Whitworth thread system. This system, introduced in 1841, was the first national standard for screw threads in the UK and is still used in certain applications today. BSW bolts are characterized by their distinct thread design and are highly valued for their durability, strength, and historical significance in mechanical and structural applications.

In this article, we’ll explore the unique features of BSW bolts, their applications, and why they remain an important choice in many industries.

What Are BSW Bolts?

BSW bolts are bolts that follow the British Standard Whitworth (BSW) thread specification. The BSW system features a 55-degree thread angle and is used for creating bolts and nuts with specific thread profiles. BSW bolts are typically used in older machinery, as well as in some modern applications where the use of the Whitworth thread is still required.

One of the distinguishing features of BSW bolts is the coarser pitch compared to other modern thread systems like ISO (metric) threads. The coarser thread profile allows these bolts to hold well in softer materials and provides more resistance to loosening due to vibrations.

Key Features of BSW Bolts

Thread Profile

BSW bolts have a distinct thread profile, which is different from other common bolts like ISO threads. The 55-degree angle of the thread allows for a stronger grip, especially in softer materials, making BSW bolts suitable for a wide range of applications.Coarser Thread Pitch

The BSW thread features a coarser pitch, meaning the threads are spaced further apart. This provides a better grip in certain materials and helps to prevent the bolt from loosening under vibrations or dynamic forces. BSW bolts are preferred in applications where high torque resistance is required.Material Variety

BSW bolts are made from a variety of materials, including carbon steel, stainless steel, and alloys, depending on the application. This variety ensures that the bolts can withstand the required stress levels and environmental conditions.Versatility in Size and Length

BSW bolts are available in a wide range of sizes and lengths, offering flexibility for use in various machinery and structural applications. Whether you're working with small, intricate components or large, heavy-duty machinery, BSW bolts provide an adaptable solution.

Applications of BSW Bolts

Despite the introduction of newer standards such as ISO and Unified threads, BSW bolts are still used in several key industries due to their unique properties. Some common applications include:

Automotive Industry

In the automotive industry, BSW bolts were once widely used for securing parts and components. While newer thread standards are more commonly used today, BSW bolts are still found in older vehicles or specific machinery that utilizes the British Standard Whitworth thread system.Machinery and Equipment

BSW bolts are used in machinery that was designed or built before the adoption of modern thread standards. These bolts are still required for maintenance, repair, and replacement in older equipment that relies on BSW threads for fastening.Marine and Aerospace Industries

BSW bolts were historically used in both the marine and aerospace industries. In some cases, these bolts are still utilized today in retrofitting and repair of older equipment that was designed using the Whitworth system.Construction and Structural Engineering

In construction and structural applications, BSW bolts are often used for securing large steel structures, particularly in cases where vintage designs or restoration projects are involved. The coarse threads of the BSW bolts provide a solid hold in softer metals and materials.

Advantages of BSW Bolts

Strong Torque Resistance

One of the major advantages of BSW bolts is their ability to resist loosening due to vibrations or dynamic forces. The coarser thread profile of these bolts helps provide better torque resistance and can be especially beneficial in environments where constant movement or vibration is present.Compatibility with Older Equipment

BSW bolts are essential for retrofitting and repairing older machinery, vehicles, and structures that were originally designed with the Whitworth thread system. Their use ensures compatibility and avoids the need for re-engineering or replacing components.Durable and Reliable

BSW bolts are known for their durability and reliability, making them suitable for demanding applications where strength and longevity are critical. The British Standard Whitworth system has been proven to withstand high levels of stress and environmental exposure.Ease of Use

The coarse thread design of BSW bolts allows for easier insertion and removal, even in challenging conditions. This feature makes them ideal for maintenance work where ease of access and efficiency are essential.

Why Choose BSW Bolts?

Historical and Practical Significance

BSW bolts have a long history of use in machinery, automotive, marine, and construction industries. While newer thread standards are now more common, the BSW bolt remains an important choice for maintaining and repairing legacy systems that were built using the Whitworth thread design.Versatility for Specialized Applications

For specific projects, particularly when dealing with older equipment or systems, BSW bolts remain an essential fastener. Their ability to provide secure fastening under high torque and vibration makes them a valuable component in various industrial applications.Easy Sourcing for Vintage Equipment

If you're working with vintage machinery or conducting a restoration project, BSW bolts are often readily available in many different sizes and materials, making it easier to find the right component for the job.

Conclusion

BSW bolts continue to play an important role in industries that rely on vintage or legacy equipment. Known for their durability, torque resistance, and ease of use, these bolts are essential for applications in automotive, machinery, marine, and construction industries. Whether you're maintaining older equipment or working on restoration projects, BSW bolts offer a reliable and historically significant fastening solution.

If you're looking for BSW bolts for your next project, we offer a wide range of sizes, materials, and finishes to meet your specific needs. Contact us today for more information on how we can support your fastening requirements.

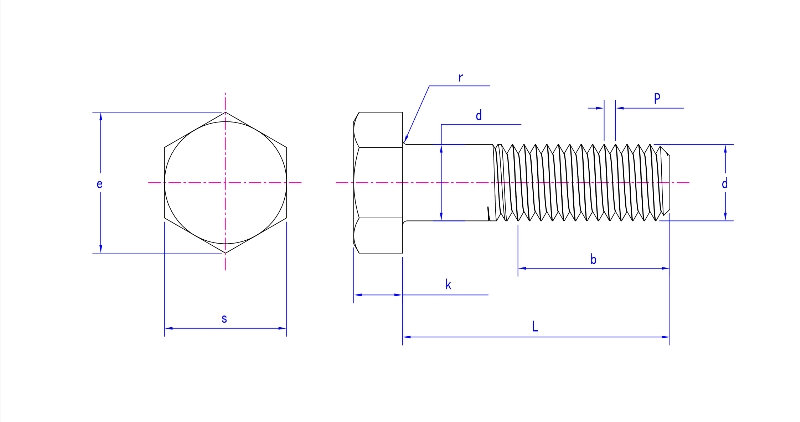

Product drawing