Hex Head Flange Bolts ASME B18.2.1-8

Product: ASME B18.2.1-8 Hex Head Flange Bolts

Property Class: Gr307A, 307B, 325, A449, A490 2,5,8

Finish:Zinc Plating(Yellow Zinc, Zinc Blue,Rinse Color), Black, Phosphate & Oil, Zinc Phosphate, Hot-dip Galvanized(HDG),Dacromet, Geomet

Material:Steel

Export country: USA, Japan, Australia, Europe and so on

Support customer customization

Hexagonal flange bolts ASME B18.2.1-8 are bolt types designed and produced according to the American fastener manufacturing standard ASME B18.2.1. The material of hexagonal flange bolts ASME B18.2.1-8 can be selected according to specific needs to meet the requirements of different engineering environments. Hexagonal flange bolts ASME B18.2.1-8 are widely used in machinery manufacturing, valve accessories, chemical equipment, marine engineering and other fields, and their excellent performance and reliable connection effect are widely recognized. As a high-performance fastener, hexagonal flange bolts ASME B18.2.1-8 have wide applicability and reliable connection performance. It is designed and produced in strict accordance with the American fastener manufacturing standard ASME B18.2.1, ensuring the quality and stability of the product. It has broad application prospects in machinery manufacturing, valve accessories, chemical equipment, marine engineering and other fields.

Pictures

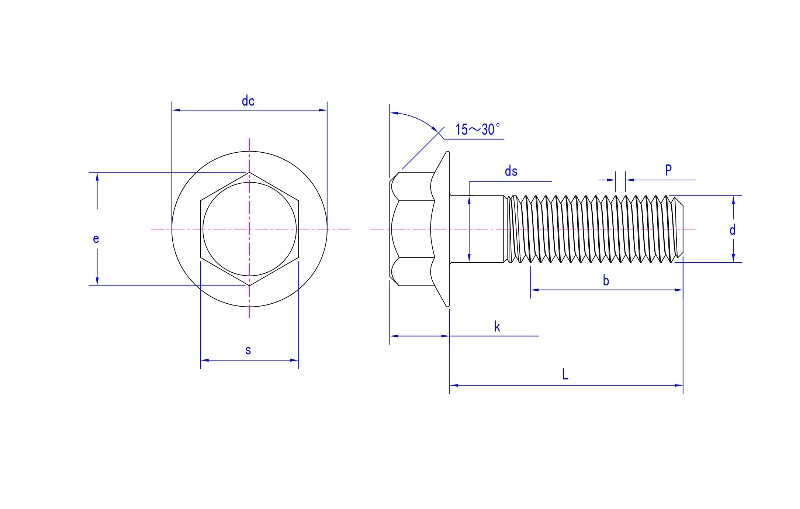

Product drawing

Product Specification

Size | 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | 9/16 | 5/8 | 3/4 | |

P | 20|28|32 | 18|24|32 | 16|24|32 | 14|20|28 | 13|20|28 | 12|18|24 | 11|18|24 | 10|16|20 | |

ds | max | 0.25 | 0.3125 | 0.375 | 0.4375 | 0.5 | 0.5625 | 0.625 | 0.75 |

min | 0.245 | 0.3065 | 0.369 | 0.4305 | 0.493 | 0.5545 | 0.617 | 0.741 | |

s | max | 0.375 | 0.5 | 0.5625 | 0.625 | 0.75 | 0.8125 | 0.9375 | 1.125 |

min | 0.367 | 0.489 | 0.551 | 0.612 | 0.736 | 0.798 | 0.922 | 1.125 | |

e | max | 0.433 | 0.577 | 0.65 | 0.722 | 0.866 | 0.938 | 1.083 | 1.299 |

min | 0.409 | 0.548 | 0.618 | 0.685 | 0.825 | 0.895 | 1.034 | 1.234 | |

dc max | 0.56 | 0.68 | 0.81 | 0.93 | 1.07 | 1.19 | 1.33 | 1.59 | |

k max | 0.28 | 0.32 | 0.39 | 0.46 | 0.51 | 0.57 | 0.62 | 0.73 | |

Support customer customization | |||||||||

Some introduction about our company

Application

Jinan Star Company specializes in the production of fastener products. Our bolts, nuts and other products are widely used in machinery, railways, automobiles, construction, electrical, bridges, communications, firefighting and other industries.

Workshop

The workshop of Jinan Star Fastener Co., Ltd. is the core area of the company's production and manufacturing, with advanced production equipment. The reasonable layout of the workshop and the scientific production process ensure the efficient production and high-quality output of fastener products.

Certification

Jinan Star Fastener Co., Ltd. has obtained the 2015 version of ISO9001 quality management system certification through the scientific management of leaders of various departments and the pursuit of high quality for bolts and other fasteners. In addition, the laboratory owned by Star Company has obtained the certification in 2017. It passed the national CNAS certification in 2018, and the company passed the European CE certification in 2018.

Production equipment

In order to meet the needs of different customers, the company has introduced a series of advanced production equipment, such as multi-station cold heading machines, thread rolling equipment, heat treatment equipment, shot blasting machines, sand blasting machines, electroplating lines and other surface treatment equipment, and fully automatic packaging equipment. These equipment not only improve production efficiency, but also ensure the consistency and stability of product quality.

Testing Equipment

Jinan Star Fastener Company attaches great importance to product quality and is equipped with complete quality inspection equipment, such as tensile testing machines, torque testers,metallographic microscopes, optical projectors, salt spray test chambers, coating thickness gauges, etc., which are used to test the tensile strength and elongation of fastener products and evaluate the mechanical properties of products. These equipment ensure that every link from raw materials to finished products can be strictly controlled in quality.

Service

1. Customize ideal fasteners: Customize services based on provided samples and drawings.

2. The perfect fastening solution for your problems with 60 years of experience: Wide selection of parts.

3. Professional Manufacturer: All our fasteners are designed and manufactured according to buyers' specifications and performance.

4. Quality assurance: Durability testing and key technology design can improve the service life of fasteners.

5. Cost-effective: Wide selection of parts, supplied by professional factories, at competitive prices.

FAQ

1. About product quality

Q: How do you ensure product quality?

Answer: We produce in strict accordance with international and industry standards. Each batch of products will undergo strict quality inspection to ensure that the products meet the highest quality standards. At the same time, we use high-quality materials and advanced production processes to ensure product stability and durability.

2. About customized services

Q: Can you provide customized services?

Answer: Yes, we provide personalized customization services. You can choose the appropriate materials, sizes, surface treatments, etc. according to your specific needs. We will customize exclusive fastener products for you according to your requirements.