Stainless Steel Hex Bolts

1.High-Strength Steel Hex Head Bolts AS 1252

2.Source bolt manufacturer, own factory: with price advantage, eliminating the price difference of middlemen.

3.Adopt the industry's top high-quality thickened steel, high stability and long-lasting durability.

4.Support customer customization.

5.Professional sales and after-sales service, welcome to inquire at any time.

6.Delivery on time.

Stainless steel hex bolts are a cornerstone of modern fastening systems, offering exceptional corrosion resistance, mechanical strength, and long-term durability in demanding environments. Widely used in construction, machinery, marine, and chemical industries, these bolts combine structural reliability with resistance to environmental degradation. This comprehensive, SEO-optimized article provides an in-depth look at stainless steel hex bolts, covering materials, design standards, engineering considerations, and application guidelines.

What Are Stainless Steel Hex Bolts?

A stainless steel hex bolt is a six-sided head bolt made from corrosion-resistant stainless steel alloys. It features a fully or partially threaded shank and is typically used with a nut or tapped hole. These bolts are preferred in applications where strength, aesthetic appeal, and resistance to rust and oxidation are essential.

Materials and Grades

Stainless steel hex bolts are manufactured from a range of alloys, with the most common including:

| Grade | Composition | Characteristics | Common Use |

|---|---|---|---|

| A2-70 (304) | Chromium-Nickel | Good corrosion resistance, non-magnetic | General-purpose, food-grade, outdoor |

| A4-70 / A4-80 (316) | Chromium-Nickel-Molybdenum | Superior corrosion resistance in saltwater or acidic conditions | Marine, chemical processing |

| 410 / 420 | Martensitic stainless | High hardness, moderate corrosion resistance | Tools, wear-resistant applications |

| 17-4PH | Precipitation-hardened SS | High strength and corrosion resistance | Aerospace, oil & gas |

Industry Standards and Specifications

Stainless steel hex bolts must comply with national and international standards to ensure performance and compatibility.

| Standard | Region | Description |

|---|---|---|

| ISO 4014 / 4017 | Global | Partially / fully threaded hex bolts (metric) |

| DIN 931 / 933 | EU | Metric bolts, partially / fully threaded |

| ASTM F593 | USA | Standard for stainless steel bolts and studs |

| ASME B18.2.1 | USA | Hex bolts with inch dimensions |

| EN 15048 / EN 14399 | EU | Structural bolting assemblies |

Tensile strength

Thread pitch

Tolerance class

Markings and test methods

Engineering Design Considerations

1. Load-Bearing Capacity

Depends on bolt diameter, thread length, and material yield strength.

A2-70 bolts have a minimum tensile strength of 700 MPa.

2. Corrosion Resistance

316 stainless (A4-70/80) resists chlorides, acid rain, and salt spray, making it ideal for offshore and chemical environments.

3. Thread Design

Metric thread (e.g., M10x1.5) or UNC/UNF (e.g., 3/8”-16) must match nut/receiver threading.

Threads can be rolled (stronger, smoother) or cut (better for small batches and repair).

4. Temperature Limits

A2 stainless: -200°C to +300°C

A4 stainless: -200°C to +400°C

17-4PH: Up to 600°C with high strength retention

Finishing and Surface Treatments

Although stainless steel resists corrosion, additional treatments can improve function or aesthetics:

| Finish | Purpose |

|---|---|

| Passivation | Removes free iron for enhanced corrosion resistance |

| Electropolishing | Smooths and brightens the surface |

| PTFE Coating | Provides low-friction surface for torque control |

| Black Oxide | Dark appearance, moderate corrosion resistance |

Common Applications

| Industry | Use Cases |

|---|---|

| Construction | Structural steel connections, curtain walls |

| Marine | Boat hulls, docks, underwater fasteners |

| Food & Beverage | Processing machinery, sanitary equipment |

| Automotive | Engine components, frame assemblies |

| Energy | Solar panel mounting, wind turbines |

| Pharmaceuticals | Cleanroom equipment and piping systems |

Advantages of Stainless Steel Hex Bolts

✅ Corrosion Resistance – Long-lasting in harsh or wet environments

✅ Strength-to-Weight Ratio – Good tensile strength for structural use

✅ Aesthetic Appeal – Clean, polished look for exposed applications

✅ Hygiene – Ideal for food-safe and cleanroom installations

✅ Longevity – Lower maintenance and replacement cost

Installation Guidelines

Use matching stainless nuts/washers to avoid galvanic corrosion

Apply anti-seize compound on threads to prevent galling

Tighten using calibrated torque wrenches to prevent overloading

Use locking washers or thread lockers for high-vibration environments

Frequently Asked Questions (FAQs)

Q1: What’s the difference between A2-70 and A4-80 bolts?

A: A4-80 has higher tensile strength (800 MPa vs. 700 MPa) and superior corrosion resistance due to added molybdenum, ideal for marine or chemical applications.

Q2: Can stainless steel bolts rust?

A: While stainless steel resists rust, it can corrode in highly saline, acidic, or chlorinated environments if not properly maintained or passivated.

Q3: Are stainless bolts magnetic?

A: Austenitic grades (A2, A4) are non-magnetic in annealed condition. Martensitic grades (410, 420) are magnetic.

Q4: How do I prevent thread galling?

A: Use anti-seize lubricant, avoid over-tightening, and consider using coarse threads or duplex stainless steel in high-stress situations.

Q5: What sizes are available?

A: Standard metric sizes range from M3 to M36, and inch series from 1/4" to 1 1/2". Custom lengths, threads, and coatings are available upon request.

Case Example: Stainless Hex Bolts in Bridge Construction

Project: Coastal suspension bridge

Bolt Spec: A4-80 stainless steel, M20x80

Coating: Electropolished

Performance: Withstood 15 years of salt spray exposure without visible corrosion

Outcome: 40% reduction in maintenance compared to galvanized fasteners

Conclusion

Stainless steel hex bolts offer a versatile, high-performance fastening solution for applications where corrosion resistance, strength, and long-term reliability are critical. With compliance to international standards like ISO, ASTM, and DIN, they ensure mechanical integrity across industries.

Whether for structural steelwork, offshore platforms, or hygienic installations, selecting the right stainless hex bolt enhances both safety and lifespan of assemblies.

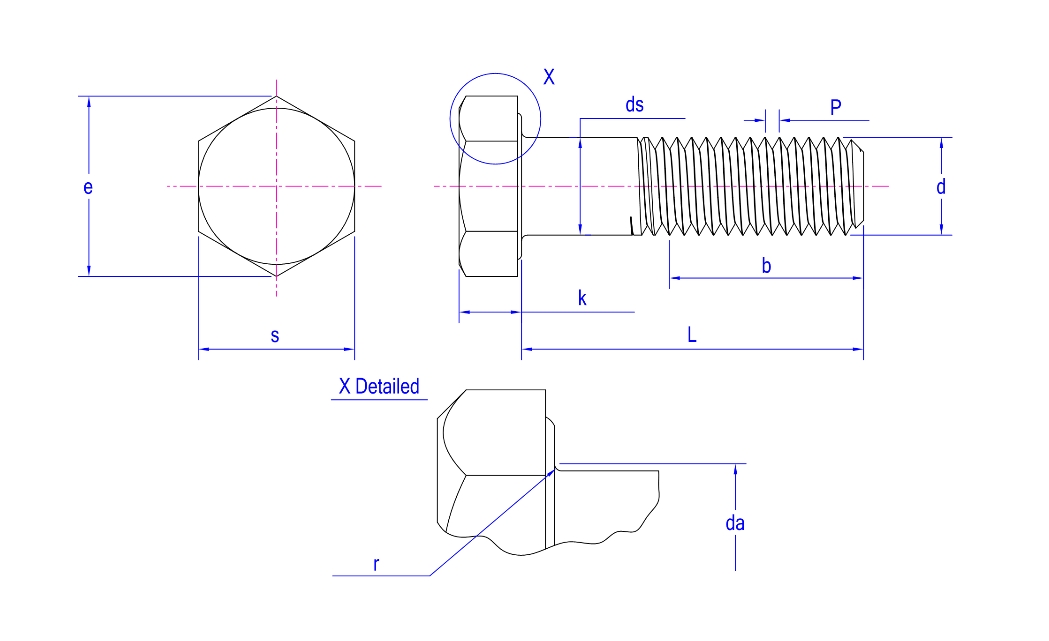

Pictures

Product drawing