DIN 938 bm=1d Double-ended Bolts

Product: DIN 938 bm=1d Double-ended Bolts

Property Class:4.6,4.8,5.6,5.8,8.8,10.9,12.9,

A2-70, A4-70,A4-80

Finish:Zinc Plating(Yellow Zinc, Zinc Blue, Rinse Color), Black, Phosphate & Oil, Zinc Phosphate, Hot-dip Galvanized(HDG),Dacromet, Geomet

Material:Steel

Export country: USA, Japan, Australia, Europe and so on

Support customer customization

DIN 938 bm=1d Double-ended Bolts are an essential fastening component in many engineering, construction, and machinery applications. Known for their high strength, dimensional accuracy, and versatile usability, these bolts are manufactured according to strict DIN 938 standards, ensuring quality and reliability across industries. Whether you're assembling engines, heavy machinery, or structural frames, understanding the features and advantages of DIN 938 bm=1d Double-ended Bolts can help you choose the most suitable fastener for your project.

✅ What are DIN 938 bm=1d Double-ended Bolts?

DIN 938 bm=1d Double-ended Bolts are precision-engineered fasteners with threads at both ends and an unthreaded shank in the middle. The designation “bm=1d” refers to the thread length on the shorter end, which is equal to one nominal diameter (1d) of the bolt. These bolts are ideal for situations where one end needs to be permanently screwed into a tapped hole, leaving the other end free for a removable nut.

The DIN 938 standard defines critical dimensions, thread types, and material specifications for these bolts, ensuring global consistency and compatibility.

? Key Features of DIN 938 bm=1d Double-ended Bolts

Threading on Both Ends: Designed for dual fastening – one end for permanent anchoring, the other for detachable assembly.

bm=1d Specification: Guarantees a fixed short thread length, ideal for precise fitment in base components.

Unthreaded Middle Section: Maintains bolt strength and reduces stress concentration.

High Tensile Strength: Manufactured from alloy steel, stainless steel, or carbon steel to support demanding loads.

Corrosion Resistance: Available in zinc-plated, black oxide, or hot-dip galvanized coatings.

DIN Standard Compliance: Ensures interchangeability and quality assurance in global markets.

? Applications of DIN 938 bm=1d Double-ended Bolts

The unique geometry and robust performance of DIN 938 bm=1d Double-ended Bolts make them ideal for:

Engine Block Assembly: Commonly used in mounting cylinder heads and engine covers.

Industrial Machinery: Facilitates secure connections that may require disassembly during maintenance.

Automotive Components: Used where strong, vibration-resistant joints are essential.

Construction & Steel Fabrication: Ensures precision alignment and load-bearing performance.

Power Generation Equipment: Supports high-stress assemblies that require consistent torque.

⚙️ Advantages of DIN 938 bm=1d Double-ended Bolts

1. Precision Fit and Alignment

The bm=1d threading specification allows for exact insertion into threaded holes, offering superior axial alignment and ensuring minimal movement under dynamic loads.

2. Ease of Maintenance

Unlike fully threaded bolts, DIN 938 bm=1d Double-ended Bolts allow for easy removal of one side during inspection or part replacement—especially useful in machines requiring periodic service.

3. Superior Strength

The unthreaded shank portion of the bolt distributes stress evenly, reducing the risk of shearing and fatigue. This makes them ideal for high-torque or impact-heavy environments.

4. DIN Standard Interchangeability

As a globally recognized standard, DIN 938 ensures your bolts are compatible with various international systems, making sourcing and replacements fast and efficient.

? Technical Specifications (Sample)

| Property | Value |

|---|---|

| Standard | DIN 938 |

| Thread Type | Metric (Coarse/Fine) |

| Thread Length (Short End) | 1d (Nominal Diameter) |

| Material | Carbon Steel, Alloy Steel, Stainless Steel |

| Finish | Plain, Zinc-plated, Galvanized |

| Sizes | M6 to M48 and custom sizes available |

| Tolerance | As per ISO 965-2 |

? How to Select the Right DIN 938 bm=1d Double-ended Bolts

When choosing the correct DIN 938 bm=1d Double-ended Bolt, consider:

Thread size (M6–M48 or custom)

Material type based on load and environmental exposure

Coating or finish for corrosion protection

Application-specific requirements, including tensile strength and installation conditions

For critical applications such as engine mounting, heavy-duty presses, or precision tooling, always ensure the bolts conform to certified DIN 938 bm=1d specifications.

? Why Use DIN 938 bm=1d Double-ended Bolts for Global Projects?

The global standardization of DIN 938 bm=1d Double-ended Bolts makes them an excellent choice for international projects requiring consistency, reliability, and fast replacement. Industries from automotive manufacturing in Germany to oil refineries in the Middle East trust these bolts for their unmatched performance and engineering integrity.

Pictures

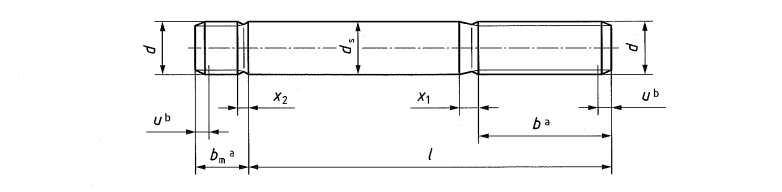

Product drawing

Product Specification

Size | M3 | M4 | M5 | M6 | M7 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | M33 | M36 | M39 | M42 | M45 | M48 | M52 | |

bm | 3.0 | 4.0 | 5.0 | 6.0 | 7.0 | 8.0 | 10.0 | 12.0 | 14.0 | 16.0 | 18.0 | 20.0 | 22.0 | 24.0 | 25.0 | 30.0 | 32.0 | 35.0 | 38.0 | 42.0 | 45.0 | 48.0 | 52.0 | |

b | a | 12 | 14 | 16 | 18 | 20 | 22 | 26 | 30 | 34 | 38 | 42 | 46 | 50 | 54 | 60 | 66 | 72 | 78 | 84 | 90 | 96 | 102 | 110 |

b | 18 | 20 | 22 | 24 | 26 | 28 | 32 | 36 | 40 | 44 | 48 | 52 | 56 | 60 | 66 | 72 | 78 | 84 | 90 | 96 | 102 | 108 | 116 | |

c | / | / | / | / | / | / | 45 | 49 | 53 | 57 | 61 | 65 | 69 | 73 | 79 | 85 | 91 | 97 | 103 | 109 | 115 | 121 | 129 | |

ds | max | 3.0 | 4.0 | 5.0 | 6.0 | 7.0 | 8.0 | 10.0 | 12.0 | 14.0 | 16.0 | 18.0 | 20.0 | 22.0 | 24.0 | 27.0 | 30.0 | 33.0 | 36.0 | 39.0 | 42.0 | 45.0 | 48.0 | 52.0 |

min | 2.86 | 3.82 | 4.82 | 5.82 | 6.78 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | 26.67 | 29.67 | 32.61 | 35.61 | 39.61 | 41.61 | 44.61 | 47.61 | 51.54 | |

x1(d) | 1.25 | 1.75 | 2.0 | 2.5 | 2.5 | 3.2 | 3.8 | 4.3 | 5.0 | 5.0 | 6.3 | 6.3 | 6.3 | 7.5 | 7.5 | 9.0 | 9.0 | 10.0 | 10.0 | 11.0 | 11.0 | 12.5 | 12.5 | |

x2(d) | 0.7 | 0.7 | 0.9 | 1.0 | 1.25 | 1.6 | 1.9 | 2.2 | 2.5 | 3.2 | 3.2 | 3.2 | 3.8 | 3.8 | 4.5 | 4.5 | 5.0 | 5.0 | 5.5 | 5.5 | 6.3 | 6.3 | ||

Some introduction about our company

Application

Jinan Star Company specializes in the production of fastener products. Our bolts, nuts and other products are widely used in machinery, railways, automobiles, construction, electrical, bridges, communications, firefighting and other industries.