Flanged Metric Bolts

1.ASME B18.2.3.4M Metric Hex Head Flange Bolts

2.Source bolt manufacturer, own factory: with price advantage, eliminating the price difference of middlemen.

3.Adopt the industry's top high-quality thickened steel, high stability and long-lasting durability.

4.Support customer customization.

5.Professional sales and after-sales service, welcome to inquire at any time.

6.Delivery on time.

Flanged Metric Bolts: Secure Fastening with Built-In Washer Support

Flanged metric bolts are specialized fasteners designed to provide strong, secure, and evenly distributed clamping force. These bolts feature an integrated flange under the hex head, which acts like a built-in washer to spread the load and reduce the risk of damage to the bolted material. Whether used in automotive, construction, machinery, or industrial applications, flanged metric bolts ensure enhanced grip, ease of installation, and reliable performance.

Made according to international metric standards, flanged metric bolts are widely used across global industries where precision, strength, and consistency matter.

What Are Flanged Metric Bolts?

Flanged metric bolts are hex head bolts with a wide, flat flange that extends beneath the head. This flange helps to distribute the clamping force over a larger surface area, minimizing stress concentrations and improving the stability of the fastening. Unlike standard bolts, flanged metric bolts eliminate the need for a separate washer, simplifying assembly while maintaining high mechanical strength.

Key features of flanged metric bolts include:

Integrated Flange Head: Acts as a washer to reduce pressure and enhance load distribution.

Hex Drive: Allows easy installation with standard tools.

Metric Threading: Designed to fit metric nuts and components.

Various Grades and Finishes: Available in zinc-plated, black oxide, stainless steel, and more.

Benefits of Flanged Metric Bolts

Improved Load Distribution

The built-in flange of flanged metric bolts reduces surface stress, preventing the bolt from pulling through soft materials and enhancing overall joint integrity.Simplified Installation

Because the flange replaces the need for a separate washer, flanged metric bolts reduce part count and streamline the assembly process.High Vibration Resistance

The flange provides additional surface contact and resistance to loosening in high-vibration environments, making flanged metric bolts ideal for engines and heavy equipment.Corrosion Protection

Many flanged metric bolts are available with corrosion-resistant finishes such as zinc or stainless steel, making them suitable for indoor and outdoor use.Consistent Clamping Force

With standardized thread pitch and dimensions, flanged metric bolts deliver uniform tension and load-bearing capabilities across multiple applications.

Applications of Flanged Metric Bolts

Flanged metric bolts are widely used in:

Automotive Assemblies: Engine mounts, chassis, and suspension systems.

Heavy Machinery: Gearboxes, pumps, and hydraulic systems.

Construction and Infrastructure: Steel framework, bridges, and scaffolding.

Metal Fabrication: Equipment enclosures, control panels, and bracket mounting.

Electrical Installations: Panels, conduit supports, and grounding systems.

Their versatility, strength, and reliability make flanged metric bolts essential components in high-stress and precision-demanding environments.

Types of Flanged Metric Bolts

Serrated Flanged Metric Bolts

These feature radial serrations under the flange to bite into the material, offering greater resistance to loosening under vibration.Non-Serrated Flanged Metric Bolts

Smooth under the flange, ideal for applications where surface protection is critical.Fully Threaded vs. Partially Threaded

Choose fully threaded flanged metric bolts for thin materials and maximum engagement, or partially threaded types for higher shear strength.Different Grades

Available in property classes such as 8.8, 10.9, and 12.9 depending on the required strength.

Choosing the Right Flanged Metric Bolts

When selecting flanged metric bolts, consider the following:

Bolt Length and Diameter: Based on the thickness and type of materials.

Thread Pitch: Ensure compatibility with corresponding nuts or threaded holes.

Material and Finish: Select corrosion-resistant options for outdoor or marine use.

Serration Requirement: Serrated for high vibration; non-serrated for smoother finishes.

Always refer to relevant ISO or DIN standards for dimensional and strength specifications of flanged metric bolts.

Conclusion

Flanged metric bolts are a superior fastening solution where strength, stability, and efficient load distribution are essential. Their built-in flange offers numerous advantages—from improved vibration resistance to simplified installation—making them ideal across automotive, industrial, and construction sectors. With reliable performance and consistent quality, flanged metric bolts are the go-to choice for high-performance fastening systems.

Pictures

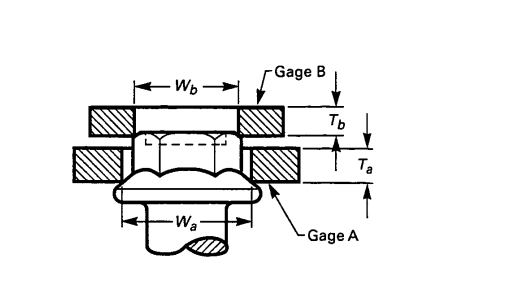

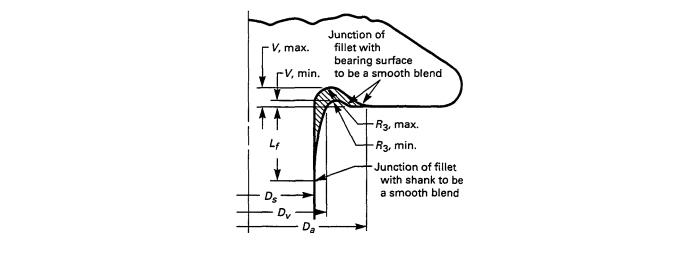

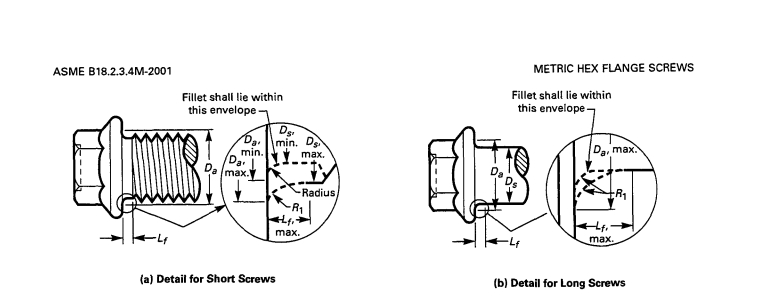

Product drawing

Product Specification

Gaging of Head | M5 | M6 | M8 | M10 | M12 | M14 | M16 | |

Wa | max | 8.09 | 9.25 | 11.56 | 15.02 | 17.33 | 20.79 | 24.26 |

min | 8.08 | 9.24 | 11.55 | 15.01 | 17.32 | 20.78 | 24.25 | |

Ta | max | 2.30 | 2.90 | 3.80 | 4.30 | 5.40 | 5.60 | 6.80 |

min | 2.29 | 2.89 | 3.79 | 4.29 | 5.39 | 5.59 | 6.79 | |

Wb | max | 7.43 | 8.55 | 10.79 | 14.07 | 16.31 | 19.67 | 22.57 |

min | 7.42 | 8.54 | 10.78 | 14.06 | 16.30 | 19.66 | 22.56 | |

Tb min | 3.0 | 3.0 | 4.0 | 4.0 | 5.0 | 5.0 | 6.0 | |

Support customer customization | ||||||||

Size type F | M5 | M6 | M8 | M10 | M12 | M14 | M16 | |

Da max | 5.7 | 6.8 | 9.2 | 11.2 | 13.7 | 15.7 | 17.7 | |

Da min | for short | 5.1 | 6.2 | 8.3 | 10.2 | 12.2 | 14.1 | 16.5 |

Ds min | for short | 4.36 | 5.21 | 7.04 | 8.86 | 10.68 | 12.50 | 14.50 |

Lf max | for long | 1.4 | 1.6 | 2.1 | 2.1 | 2.1 | 2.1 | 3.2 |

for short | 0.7 | 0.9 | 1.1 | 1.2 | 1.3 | 1.4 | 1.6 | |

R1 min | 0.2 | 0.25 | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | |

Support customer customization | ||||||||

Size type U | M5 | M6 | M8 | M10 | M12 | M14 | M16 | |

Da max | 6.2 | 7.5 | 10.0 | 12.5 | 15.2 | 17.7 | 20.5 | |

Dv max | 5.5 | 6.6 | 8.8 | 10.8 | 12.8 | 14.8 | 17.2 | |

Ds min | for short | 4.36 | 5.21 | 7.04 | 8.86 | 10.68 | 12.50 | 14.50 |

Lf max | 1.4 | 1.6 | 2.1 | 2.1 | 2.1 | 2.1 | 3.2 | |

R3 | max | 0.25 | 0.26 | 0.36 | 0.45 | 0.54 | 0.63 | 0.72 |

min | 0.10 | 0.11 | 0.16 | 0.20 | 0.24 | 0.28 | 0.32 | |

V | max | 0.15 | 0.20 | 0.25 | 0.30 | 0.35 | 0.45 | 0.50 |

min | 0.05 | 0.05 | 0.10 | 0.15 | 0.15 | 0.20 | 0.25 | |

Support customer customization | ||||||||

Some introduction about our company

Application

Jinan Star Company specializes in the production of fastener products. Our bolts, nuts and other products are widely used in machinery, railways, automobiles, construction, electrical, bridges, communications, firefighting and other industries.

Certification

Jinan Star Fastener Co., Ltd. has obtained the 2015 version of ISO9001 quality management system certification through the scientific management of leaders of various departments and the pursuit of high quality for bolts and other fasteners. Furthermore, the laboratory owned by Star Company obtained certification in 2017. It passed the national CNAS certification and the European CE certification in 2018.

Production equipment

In order to meet the needs of different customers, the company has introduced a series of advanced production equipment, such as multi-station cold heading machines, thread rolling equipment, heat treatment equipment, shot blasting machines, sand blasting machines, electroplating lines and other surface treatment equipment, and fully automatic packaging equipment. These equipment not only improve production efficiency, but also ensure the consistency and stability of product quality.

Our Customers

Our bolts, screws and other fasteners are exported to numerous countries such as the United States, Germany, Australia, Japan and so on. Since the factory was established in 1968, we have accumulated many long-term partners. Jinan Star has been dedicated to providing customers with high-quality bolts and other fasteners. For this reason, our products and team will be trusted by customers and move towards a brighter future together.

Packing

Service

1. Customize Flanged Metric Bolts ASME B18.2.3.4M of different specifications, sizes and materials according to the specific needs of customers. For example, if you have special requirements for parameters such as the length, diameter and thread of bolts, Jinan Star can carry out specialized production and processing.

2. Provide bolt selection guidance for customers. According to your application scenarios, load-bearing requirements and other factors, help customers choose the appropriate model of Flanged Metric Bolts ASME B18.2.3.4M to ensure that the bolts can meet the actual use needs.

3. Strictly control the quality of bolts. From raw material procurement, production and processing to finished product inspection, every link follows strict quality standards and inspection processes.

4. Promise to provide return and exchange services for customers in a timely manner and bear corresponding responsibilities when there are quality problems with bolts. 5. Cooperate with professional logistics companies to ensure that Flanged Metric Bolts ASME B18.2.3.4M products can be delivered to customers in a timely and safe manner. According to customer requirements, provide different transportation methods and distribution plans, such as express delivery, logistics, shipping, etc.

FAQ

1. What is the quality of your Flanged Metric Bolts ASME B18.2.3.4M?

Flanged Metric Bolts ASME B18.2.3.4M is produced in line with relevant standards and undergoes strict quality inspections. We provide a quality guarantee to certify its quality and performance.

2. When will the delivery be delivered?

We arrange order production and delivery in accordance with the contract. In case of special circumstances causing delay, we will communicate with customers in advance and discuss solutions.

3. Can you please give me the best price?

Sure. We will offer you the best price. The product price depends on factors like quantity, specification, and material. Feel free to consult us and we'll provide a reasonable quotation.