Metric Fine Thread Bolts

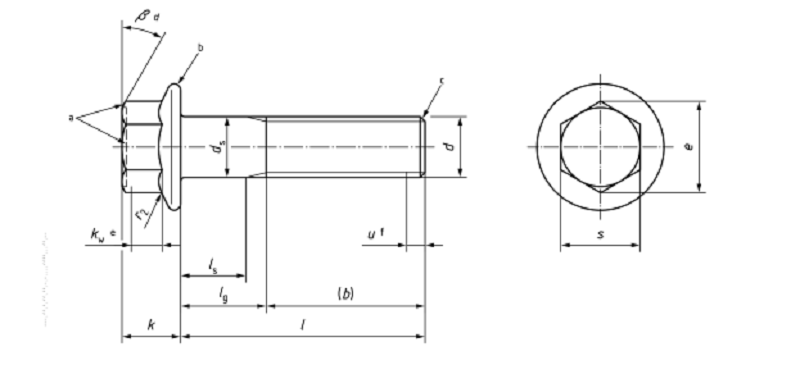

1.ISO 15072 Hex Head Flange Bolts with Fine Pitch Thread-Small Series-Type F

2.Source bolt manufacturer, own factory: with price advantage, eliminating the price difference of middlemen.

3.Adopt the industry's top high-quality thickened steel, high stability and long-lasting durability.

4.Support customer customization.

5.Professional sales and after-sales service, welcome to inquire at any time.

6.Delivery on time.

Metric Fine Thread Bolts: An Essential Guide

When it comes to securing components in machinery, automotive, and industrial applications, Metric Fine Thread Bolts are an essential fastening solution. These bolts offer superior performance, precision, and strength, making them the preferred choice for critical assemblies. In this article, we will delve into the world of Metric Fine Thread Bolts, explaining what they are, their benefits, applications, and why they are ideal for a variety of projects.

What are Metric Fine Thread Bolts?

Metric Fine Thread Bolts are fasteners that feature a finer pitch than standard metric bolts. The term "fine thread" refers to the thread pattern on the bolt, which is characterized by closely spaced threads that provide a higher level of precision and increased strength compared to coarse thread bolts. Metric Fine Thread Bolts are commonly used in high-stress applications, where superior torque strength and greater resistance to vibration are required.

The metric designation refers to the ISO standard measurement system, where bolt size is measured in millimeters. These bolts are widely used in a variety of industries, including automotive, aerospace, and construction, due to their ability to withstand demanding conditions.

Key Features of Metric Fine Thread Bolts

✅ Fine Thread Pitch for Enhanced Strength

The fine thread pitch of Metric Fine Thread Bolts provides several advantages over coarse-threaded bolts. The closer spacing of the threads allows for a tighter grip, resulting in greater tensile strength and improved resistance to shear forces. This makes fine-thread bolts ideal for applications that require a high level of strength and durability.

✅ Increased Load Bearing Capacity

The increased thread density of Metric Fine Thread Bolts allows for a better load distribution across the bolt and the material it is securing. This results in improved load-bearing capacity, which is crucial in high-performance applications such as machinery, aerospace, and heavy equipment.

✅ Enhanced Precision

Metric Fine Thread Bolts are designed for applications where precision is critical. The finer threads ensure that the bolt fits securely, reducing the risk of misalignment and ensuring that the components are properly aligned. This makes them an ideal choice for precision assemblies, where even slight misalignments could cause significant problems.

✅ Improved Resistance to Vibration

One of the major benefits of Metric Fine Thread Bolts is their enhanced resistance to vibration. The finer threads create a more secure and stable connection, preventing the bolt from loosening over time. This feature is particularly useful in automotive, aerospace, and industrial machinery, where vibration is a constant concern.

Applications of Metric Fine Thread Bolts

Metric Fine Thread Bolts are used in a wide variety of applications where strength, precision, and resistance to vibration are required. Some of the most common uses include:

✅ Automotive Industry

In the automotive industry, Metric Fine Thread Bolts are used to secure engine components, suspension systems, and other critical parts. The precision and strength offered by these bolts make them ideal for high-performance engines and other mechanical systems that experience high torque and stress.

✅ Aerospace and Aviation

In the aerospace industry, Metric Fine Thread Bolts are used to secure parts of aircraft and spacecraft. Due to the high level of precision required in these industries, fine-thread bolts provide the necessary strength and alignment needed for safety and performance.

✅ Heavy Machinery and Equipment

Heavy machinery and equipment often rely on Metric Fine Thread Bolts to hold critical components together. These bolts provide the necessary strength and resistance to vibrations that are common in heavy-duty applications. Whether used in mining equipment, construction machinery, or industrial machines, these bolts ensure that parts remain securely fastened under high-stress conditions.

✅ Construction

In construction, Metric Fine Thread Bolts are often used to secure structural components, such as beams and columns. Their ability to withstand high loads and resist loosening due to vibrations makes them ideal for heavy construction projects, including bridges, buildings, and other infrastructure.

Advantages of Using Metric Fine Thread Bolts

✅ Superior Strength and Durability

The finer threads on Metric Fine Thread Bolts provide superior strength and durability, making them ideal for high-stress applications. The increased load-bearing capacity ensures that the bolt can withstand forces that might cause other fasteners to fail, resulting in longer-lasting and more reliable assemblies.

✅ Improved Vibration Resistance

Vibration is a major issue in many industries, from automotive to industrial machinery. Metric Fine Thread Bolts offer excellent resistance to vibration, ensuring that the fastener remains securely in place even under dynamic conditions. This feature helps to reduce the need for frequent maintenance and tightening of fasteners.

✅ Precision and Alignment

The finer thread pitch of Metric Fine Thread Bolts ensures better precision and alignment of the components being fastened. This is particularly important in applications where misalignment can lead to malfunction or failure, such as in precision machinery and automotive components.

✅ Cost-Effective Solution

While Metric Fine Thread Bolts may cost more than coarse-thread bolts, their superior performance and longer lifespan make them a cost-effective choice in the long run. The added strength and resistance to vibration reduce the need for replacements and repairs, making these bolts a worthwhile investment for critical applications.

How to Choose the Right Metric Fine Thread Bolt

When selecting a Metric Fine Thread Bolt, there are several factors to consider:

✅ Material and Coating

The material and coating of the bolt should be chosen based on the environment in which it will be used. Stainless steel bolts are ideal for applications where corrosion resistance is important, while galvanized bolts offer additional protection against rust.

✅ Bolt Size and Thread Pitch

Choosing the right size and thread pitch is essential for ensuring a secure fit. Make sure to measure the required bolt length and thread pitch to ensure compatibility with the components being fastened. Metric fine-thread bolts are available in a variety of sizes to suit different applications.

✅ Torque Requirements

Consider the torque specifications for the application to ensure that the Metric Fine Thread Bolt can handle the required load. The right torque will prevent over-tightening or under-tightening, ensuring that the fastener provides optimal performance and security.

Conclusion

In conclusion, Metric Fine Thread Bolts are an essential component in a wide variety of industries, offering superior strength, precision, and resistance to vibration. These bolts are ideal for applications that require high-performance fasteners, such as in automotive, aerospace, heavy machinery, and construction.

Their fine thread pitch provides improved load-bearing capacity, better alignment, and increased durability compared to coarse-thread bolts. Whether you’re working on a precision assembly, a high-stress machine, or a construction project, Metric Fine Thread Bolts ensure a secure and reliable connection that will last for years to come.

By selecting the right Metric Fine Thread Bolt for your project, you can ensure the longevity and performance of your assembly, making these bolts a valuable choice for any high-performance application.

Product drawing