Flanged Hexagon Bolts

1.DIN EN 1665 Hex Flange Bolts-Heavy Series

2.Source bolt manufacturer, own factory: with price advantage, eliminating the price difference of middlemen.

3.Adopt the industry's top high-quality thickened steel, high stability and long-lasting durability.

4.Support customer customization.

5.Professional sales and after-sales service, welcome to inquire at any time.

6.Delivery on time.

A Complete Guide to Flanged Hexagon Bolts: Applications, Benefits, and Selection

When strength, stability, and assembly efficiency are paramount, Flanged Hexagon Bolts prove to be a superior fastening solution. Commonly used in heavy-duty mechanical and structural applications, these bolts combine a hexagonal head with a built-in flange to offer enhanced load distribution, reduced part count, and higher reliability. In this article, we delve into the world of Flanged Hexagon Bolts, exploring their features, advantages, uses, and how to choose the right type for your projects.

What Are Flanged Hexagon Bolts?

Flanged Hexagon Bolts are hex head bolts with an integrated circular flange at the base of the head. This flange acts as a non-spinning washer, spreading the load more evenly across the surface and preventing damage to the material being fastened. These bolts are widely appreciated for their ability to provide both high clamping force and enhanced stability without requiring additional washers or lock components.

Key Features of Flanged Hexagon Bolts

Integrated Flange

The most distinctive feature of Flanged Hexagon Bolts is the integral flange, which increases the bearing surface, distributes force more evenly, and reduces the chance of material deformation or loosening under vibration.Hex Head Design

The hexagonal head allows for easy tightening with standard tools, improving work efficiency on assembly lines or field installations.Available in Multiple Materials

These bolts come in stainless steel, carbon steel, alloy steel, and even coated variants for corrosion resistance and specific industrial environments.Optional Serrations

Serrated flanges add locking functionality, preventing unintentional loosening in dynamic or high-vibration applications.

Advantages of Using Flanged Hexagon Bolts

No Washer Needed

Eliminate the need for a separate washer, simplifying inventory and reducing installation time.Improved Load Distribution

Minimize damage to the connected parts by spreading the pressure across a larger area.Enhanced Vibration Resistance

Especially when using serrated versions, Flanged Hexagon Bolts hold tight even in vibrating systems.Corrosion Resistance

Stainless steel and coated variants resist oxidation and corrosion, extending the lifespan of the joint.Time and Cost Savings

Simplified design and quicker installation reduce labor time and associated costs.

Common Applications of Flanged Hexagon Bolts

Flanged Hexagon Bolts are utilized across a range of industries due to their versatile design and reliable performance:

Automotive and Engines

Used in connecting engine components, suspensions, and chassis where vibration resistance and high tensile strength are needed.Heavy Equipment and Machinery

Ideal for machinery frames, joints, and equipment housings that operate under heavy stress and loads.Construction and Steel Frameworks

Perfect for bolting steel beams and plates in structural applications.Electrical and HVAC Systems

Used in panel mountings and support systems that require secure and corrosion-resistant fastening.Home and DIY Projects

Great for outdoor furniture, fences, and decking, especially when exposed to moisture.

How to Select the Right Flanged Hexagon Bolts

When selecting Flanged Hexagon Bolts for your application, consider the following factors:

Material Compatibility: Match the bolt material to the environment — stainless steel for corrosion resistance, alloy steel for strength.

Flange Type: Smooth flange for delicate surfaces; serrated flange for extra grip and anti-loosening effects.

Size and Thread Pitch: Ensure proper fit with mating components to maintain structural integrity.

Coatings and Treatments: Zinc-plated, black oxide, or Dacromet coatings enhance durability in harsh environments.

Standards and Grades: Look for bolts that conform to international standards like ISO 4162, DIN 6921, or ASTM A574.

Installation Tips

Always tighten Flanged Hexagon Bolts using a calibrated torque wrench to avoid over- or under-tightening.

For serrated types, ensure the flange makes full contact with the surface to activate the locking effect.

If working in corrosive or high-temperature environments, apply anti-seize compound to avoid thread galling.

For critical assemblies, consider pairing with thread-locking adhesives for additional security.

Conclusion

Flanged Hexagon Bolts provide an efficient, high-strength fastening solution that combines the clamping advantages of a flange with the ease of a hex head. Their ability to distribute force, resist loosening, and endure harsh conditions makes them indispensable across multiple industries. Whether you're building heavy machinery or securing outdoor structures, Flanged Hexagon Bolts offer the strength and simplicity needed for reliable performance.

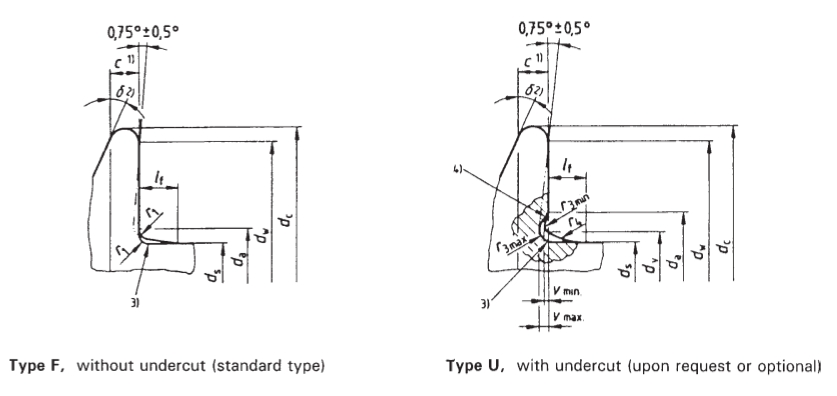

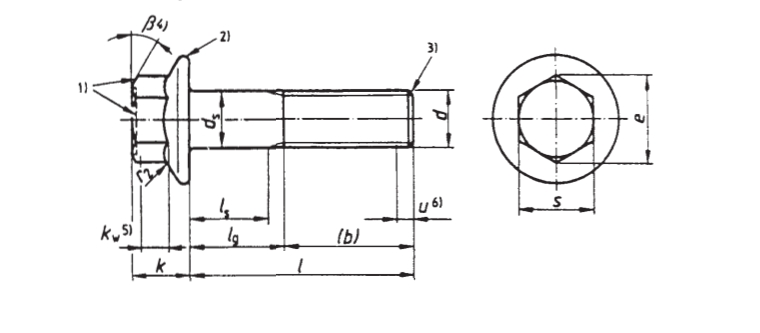

Product drawing