Stainless Steel Flange Bolts

1.GB 5789 Hex Head Flange Bolts-Heavy Series-Product Grade B

2.Source bolt manufacturer, own factory: with price advantage, eliminating the price difference of middlemen.

3.Adopt the industry's top high-quality thickened steel, high stability and long-lasting durability.

4.Support customer customization.

5.Professional sales and after-sales service, welcome to inquire at any time.

6.Delivery on time.

Everything You Need to Know About Stainless Steel Flange Bolts

When it comes to fastening systems that demand strength, corrosion resistance, and structural integrity, Stainless Steel Flange Bolts emerge as a top-tier choice. Used across industries ranging from automotive to marine engineering, these bolts offer durability and high performance in even the harshest environments. In this article, we dive into the features, benefits, applications, and selection criteria of Stainless Steel Flange Bolts, providing a comprehensive guide for engineers, builders, and procurement specialists.

What Are Stainless Steel Flange Bolts?

Stainless Steel Flange Bolts are hex head bolts with an integrated flange at the base of the head. This built-in washer-like flange distributes the load over a wider area, reducing the chance of damage to connected materials and eliminating the need for separate washers. Manufactured from stainless steel alloys such as 304 or 316, these bolts are known for their corrosion resistance, making them ideal for outdoor and marine applications.

Key Features of Stainless Steel Flange Bolts

Corrosion Resistance

Thanks to the chromium-rich composition, Stainless Steel Flange Bolts resist rust and corrosion, even in saltwater or chemical environments.Integrated Flange

The flange improves load distribution, prevents loosening, and enhances the overall stability of the joint.Strength and Durability

These bolts are made to withstand mechanical stress, making them suitable for high-vibration or high-load applications.Aesthetic Appearance

The clean, polished look of Stainless Steel Flange Bolts is ideal for exposed applications where appearance matters.Low Maintenance

Once installed, stainless steel bolts require minimal upkeep, reducing long-term costs.

Common Grades of Stainless Steel Flange Bolts

304 Stainless Steel: Offers excellent corrosion resistance and is the most common choice for general-purpose use.

316 Stainless Steel: Contains molybdenum for superior resistance to chloride corrosion, making it ideal for marine and chemical environments.

410 Stainless Steel: Known for high hardness and moderate corrosion resistance, suitable for applications requiring more wear resistance.

Advantages of Stainless Steel Flange Bolts

No need for additional washers

Withstand extreme temperatures

Maintain structural integrity over time

Compatible with various materials including aluminum, plastic, and steel

Compliant with ASTM, DIN, ISO, and other global standards

By using Stainless Steel Flange Bolts, industries can increase assembly reliability while reducing component failure and maintenance needs.

Applications of Stainless Steel Flange Bolts

Stainless Steel Flange Bolts are used in a wide array of industries:

Automotive: Engine assemblies, suspension systems, and exhaust manifolds

Marine: Boat hulls, dock components, and ship fittings

Construction: Bridges, guardrails, and outdoor metal frameworks

Industrial Machinery: Equipment housing, pressure systems, and rotating assemblies

Home Improvement: Outdoor furniture, pergolas, and deck framing

These bolts are especially valuable where exposure to moisture, chemicals, or extreme weather is common.

How to Select the Right Stainless Steel Flange Bolts

Choosing the correct Stainless Steel Flange Bolts involves evaluating:

Bolt Size and Thread Pitch: Match with your specific joint configuration

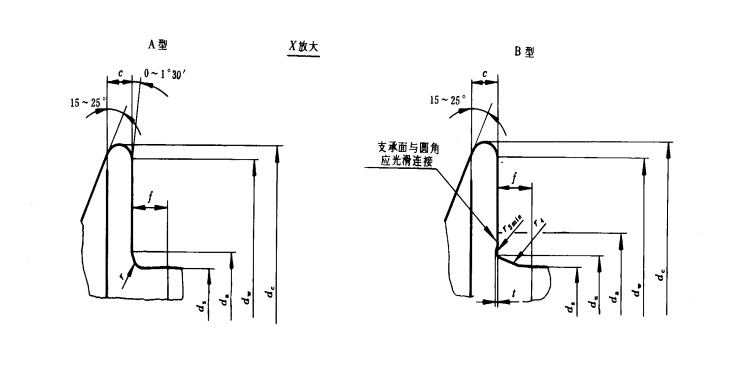

Flange Type: Serrated for anti-loosening, smooth for surface protection

Stainless Steel Grade: Depends on environmental exposure and mechanical requirements

Tensile Strength: Ensure it meets the stress demands of the application

Certifications: Look for compliance with ASTM A193, ISO 7380, or equivalent

Working with a reputable manufacturer or supplier ensures the bolts meet required specifications for performance and safety.

Installation Tips

Use a calibrated torque wrench to avoid over-tightening

Clean threads and surface areas to prevent seizing

For high-vibration applications, consider adding thread-locking compound

Apply anti-seize lubricant for bolts used in high-temperature or corrosive settings

Proper installation ensures long-term reliability and safety of the Stainless Steel Flange Bolts in operation.

Conclusion

Stainless Steel Flange Bolts are a robust, reliable, and corrosion-resistant solution for fastening challenges in demanding environments. Their integrated flange design reduces assembly complexity while increasing load-bearing capacity and vibration resistance. Whether you're building marine infrastructure, industrial equipment, or outdoor structures, Stainless Steel Flange Bolts provide the performance and durability needed for mission-critical applications.

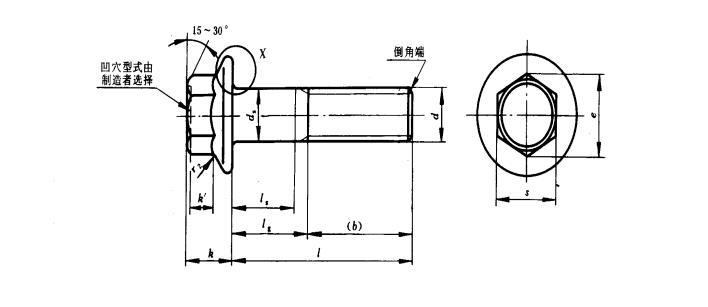

Product drawing