Non-standard U-bolt

Product: Non-standard U-bolt

Property Class:4.6,4.8,5.6,5.8,8.8,10.9,12.9,

A2-70, A4-70,A4-80

Finish:Zinc Plating(Yellow Zinc, Zinc Blue, Rinse Color), Black, Phosphate & Oil, Zinc Phosphate, Hot-dip Galvanized(HDG),Dacromet, Geomet

Material:Steel

Export country: USA, Japan, Australia, Europe and so on

Support customer customization

Non-standard U-bolt: Features, Applications, and Benefits

Introduction

The non-standard U-bolt is a highly versatile and essential fastening component used in a wide range of industries. Unlike standard U-bolts, non-standard U-bolts are custom-made to meet specific design requirements, ensuring optimal performance in unique applications. These bolts are typically used to secure pipes, rods, or other cylindrical objects to structures, offering excellent flexibility and reliability in demanding environments

Pictures

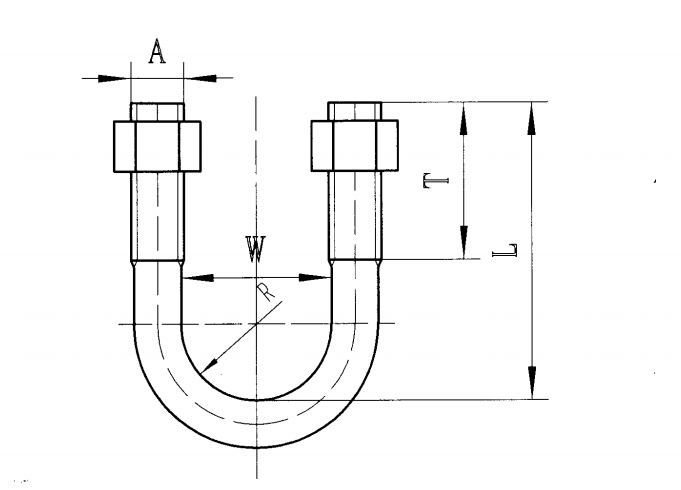

Product drawing

Product Specification

Size | A | T | L | R | W |

M10×65×21 | M10-6g | 40+-1.5 | 65+-1.25 | 10.5 | 21+-1.3 |

M10×77×27 | 50+-1.5 | 77+-1.25 | 13.5 | 27+-1.3 | |

M10×85×34 | 85+-1.5 | 17 | 34+-1.6 | ||

M10×93×43 | 93+-1.5 | 21.5 | 43+-1.6 | ||

M10×100×48 | 100+-1.5 | 24 | 48+-1.6 | ||

M10×103×51 | 103+-1.5 | 25.5 | 51+-1.9 | ||

M10×110×60 | 110+-1.5 | 30 | 60+-1.9 | ||

M12×127×76 | M12-6g | 50+-1.75 | 127+-1.75 | 38 | 76+-1.9 |

M12×140×89 | 140+-2.0 | 44.5 | 89+-2.2 | ||

M12×152×102 | 152+-2.0 | 51 | 102+-2.2 | ||

M12×165×114 | 165+-2.0 | 57 | 114+-2.2 | ||

M12×190×140 | 190+-2.0 | 70 | 140+-2.5 | ||

M12×215×165 | 215+-2.3 | 82.5 | 165+-2.5 | ||

M12×220×168 | 220+-2.3 | 84 | 168+-2.5 | ||

M16×295×219 | M16-6g | 75+-2.0 | 295+-2.6 | 109.5 | 219+-2.9 |

M20×370×273 | M20-6g | 100+-2.5 | 370+-2.6 | 136.5 | 273+-3.2 |

M20×420×324 | 420+-2.6 | 162 | 324+-3.6 | ||

M20×455×356 | 455+-3.0 | 178 | 356+-3.6 | ||

M20×505×406 | 505+-3.0 | 203 | 406+-4 | ||

M24×555×457 | M24-6g | 100+-3.0 | 555+-3.0 | 228.5 | 457+-4 |

M24×605×508 | 605+-3.5 | 254 | 508+-4.4 | ||

M24×710×610 | 710+-3.5 | 305 | 610+-4.8 | ||

Support customer customization | |||||

Key Features of Non-standard U-bolts

Custom Dimensions

One of the primary characteristics of a non-standard U-bolt is its ability to be manufactured to custom sizes and dimensions. This flexibility allows the U-bolt to fit specific application requirements, including variations in diameter, length, and thread pitch. Whether it’s for small-scale projects or heavy-duty industrial applications, non-standard U-bolts can be designed to meet exact specifications.Material Flexibility

Non-standard U-bolts can be made from a wide range of materials, such as carbon steel, stainless steel, alloy steel, or even galvanized coatings for corrosion resistance. The choice of material ensures that these bolts can be used in various environments, including those exposed to moisture, chemicals, and high temperatures.Durability and Strength

Designed to withstand harsh conditions, non-standard U-bolts are manufactured for superior tensile strength and durability. The unique shape of the U-bolt allows it to provide a secure connection between the object being fastened and the structure, even under high stress, vibration, or dynamic loads.Threading and Finishing Options

Non-standard U-bolts are available with different types of threading, such as fine or coarse threads, depending on the application requirements. They can also be finished with coatings like zinc plating or powder coating to enhance corrosion resistance, further extending the lifespan of the bolt in harsh environments.Versatile Design

The U-shape design of the bolt allows it to clamp around a cylindrical object, making it ideal for use in applications like securing pipes, cables, and rods. The open design allows for easy installation and removal, making non-standard U-bolts a convenient fastening solution for a variety of purposes.

Applications of Non-standard U-bolts

Construction and Structural Engineering

In construction, non-standard U-bolts are used to secure structural elements such as beams, pipes, and supports. The custom size and shape allow them to fit perfectly in specific structural configurations, providing a secure and stable connection between different components.Automotive and Transport

Non-standard U-bolts are commonly used in automotive and transportation applications to secure parts like suspension systems, axles, and exhaust systems. Their strength and ability to absorb shock loads make them ideal for securing critical components in vehicles and heavy machinery.Plumbing and HVAC Systems

In plumbing and HVAC systems, non-standard U-bolts are used to hold pipes, ducts, and conduits in place. The ability to custom-make the U-bolt to fit specific pipe diameters and system requirements makes it a perfect solution for securing systems in both residential and commercial buildings.Oil and Gas Industry

The oil and gas industry often requires non-standard U-bolts for securing pipes, tanks, and other cylindrical components in offshore and onshore drilling platforms. The bolts can be tailored for use in extreme conditions, such as high-pressure environments and corrosive coastal areas.Agricultural Equipment

In the agricultural sector, non-standard U-bolts are frequently used to secure components of agricultural machinery and equipment. The ability to customize the size and material ensures that the bolts can withstand the heavy-duty requirements of farming and fieldwork.

Advantages of Non-standard U-bolts

Customization for Specific Applications

The most significant advantage of non-standard U-bolts is their ability to be customized for specific application needs. Whether you require a bolt with a particular diameter, length, or material, non-standard U-bolts can be engineered to fit the precise requirements of the project.Improved Load Distribution

The U-shape design ensures that the force applied by the bolt is distributed evenly across the fastened object, providing a strong and secure connection. This design minimizes the risk of damaging the object being secured, especially in high-stress environments.Enhanced Corrosion Resistance

Non-standard U-bolts can be coated or treated with materials such as galvanization or powder coating, which provide increased resistance to corrosion. This makes them ideal for use in outdoor or marine environments where exposure to moisture and harsh chemicals is common.Flexibility in Material Choice

The availability of different materials for non-standard U-bolts, including stainless steel and alloy steel, ensures that the bolt can meet the specific demands of the environment. Whether it’s for high-temperature applications or environments prone to chemical exposure, non-standard U-bolts can be made from the most suitable materials for the job.Cost-Effectiveness

Despite being custom-made, non-standard U-bolts are often more cost-effective than alternative fastening methods. Their ability to be precisely tailored for a particular application means that they provide optimal performance, reducing the need for frequent replacements or repairs.

Non-standard U-bolts are a versatile and reliable fastening solution used in a wide range of industries and applications. Whether you need to secure pipes, machinery components, or structural elements, these custom-made bolts provide exceptional strength, durability, and flexibility. Their ability to be customized in terms of size, material, and finish makes them the ideal choice for projects that require precision and reliability. With their numerous advantages, including enhanced load distribution, corrosion resistance, and ease of installation, non-standard U-bolts offer a cost-effective and efficient fastening solution for both standard and unique applications.