DIN 7984 Hexagon Socket Low Cylinder Head Screws

Product:DIN 7984 Hexagon Socket Low Cylinder Head Screws

Property Class:4.6,4.8,5.6,5.8,8.8,10.9,12.9,A2-70, A4-70,A4-80

Finish:Zinc Plating(Yellow Zinc, Zinc Blue, Rinse Color), Black, Phosphate & Oil, Zinc Phosphate, Hot-dip Galvanized(HDG),Dacromet, Geomet

Material:Steel

Export country: USA, Japan, Australia, Europe and so on

Support customer customization

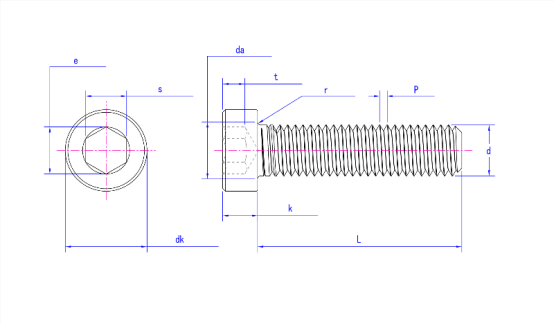

DIN 7984 is a low-profile hexagon socket head screw in the German DIN standard, also known as a thin-head hexagon socket head screw or a low cylindrical head screw. The head of this screw is designed to be thinner, suitable for use in compact spaces or applications that require a lower head height. It is driven by a hexagon socket and can be installed and removed by tools such as an hexagon wrench or a screwdriver.

Pictures

Product drawing

Product Specification

Size | M3 | M4 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | |

P | 0.5 | 0.7 | 0.8 | 1.00 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | |

da max | 3.6 | 4.7 | 5.7 | 6.8 | 9.2 | 11.2 | 13.7 | 15.7 | 17.7 | 20.2 | 22.4 | 24.4 | 26.4 | |

dk | max | 5.5 | 7.00 | 8.5 | 10 | 13 | 16 | 18 | 21 | 24 | 27 | 30 | 33 | 36 |

min | 5.32 | 6.78 | 8.28 | 9.78 | 12.73 | 15.73 | 17.73 | 20.67 | 23.67 | 26.67 | 29.67 | 32.61 | 35.61 | |

e min | 2.3 | 2.87 | 3.44 | 4.58 | 5.72 | 8.01 | 9.15 | 11.43 | 13.72 | 13.72 | 16 | 16 | 19.44 | |

k | max | 2.00 | 2.8 | 3.5 | 4.00 | 5.00 | 6.00 | 7.00 | 8.00 | 9.00 | 10 | 11 | 12 | 13 |

min | 1.86 | 2.66 | 3.32 | 3.82 | 4.82 | 5.82 | 6.78 | 7.78 | 8.78 | 9.78 | 10.73 | 11.73 | 12.73 | |

r min | 0.1 | 0.2 | 0.2 | 0.25 | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | |

s | min | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 7.025 | 8.025 | 10.025 | 12.032 | 12.032 | 14.032 | 14.032 | 17.05 |

max | 2.1 | 2.60 | 3.1 | 4.12 | 5.14 | 7.175 | 8.175 | 10.175 | 12.212 | 12.212 | 14.212 | 14.212 | 17.23 | |

t | max | 1.62 | 2.42 | 2.82 | 3.12 | 3.95 | 4.65 | 5.15 | 5.45 | 5.65 | 6.68 | 7.68 | 8.18 | 8.18 |

min | 1.38 | 2.18 | 2.58 | 2.88 | 3.65 | 4.35 | 4.85 | 5.15 | 5.35 | 6.32 | 7.32 | 7.82 | 7.82 | |

Support customer customization | ||||||||||||||

Some introduction about our company

Application

Our products are widely used in mechanical, electrical, automotive, building construction, railways, bridges, steamships, fire protection and communication system, etc.

Certification

Through scientific management, Jinan Star Fastener Co., Ltd. has obtained the 2015 version of ISO9001 quality management system certification. In 2017, the laboratory passed the national CNAS certification. In 2018, the company passed the European CE certification.

Workshop

Testing Equipment

Our company has a specialized laboratory with digital hardness testers, microscopes, universal testing machines, axial force meters, hydrogen embrittlement detection devices, magnetic particle flaw detectors, metallographic analyzers, carbon and sulfur analyzers and salt spray testing machines, etc. Experimental testing equipment is used to conduct comprehensive testing of the chemical composition of raw materials, product hardness, mechanical properties, coating thickness and corrosion resistance to ensure that all products meet standard requirements and satisfy customers.

Production equipment

Our company has more than 300 production equipment.The product production process includes: Annealing, shot blasting, cold heading, thread rolling, heat treatment, galvanizing, finished product testing, packaging, etc. are all completed in the company.

Packing

Service

1. Customized service for bolts and other products: Jinan Satr can design, manufacture and process various standard and non-standard bolts according to customer needs. Different industries have different needs. Bolt factories can provide customized solutions according to customer needs, and carry out customized processing according to customer special needs to ensure product quality and precision. At the same time, our company also provides bolts of various materials, specifications and models to meet various needs of customers.

2. Spot sales service: Spot bolts have undergone laboratory quality inspection to ensure that product quality and performance meet the standards. At the same time, the bolt factory also provides various special bolts, such as shockproof, waterproof, fireproof, etc., to meet special needs.

3. Packaging service: The packaging service of bolts can be packaged in various ways according to customer requirements, such as plastic boxes, paper boxes, leather grain cardboard, etc. Different types of products use different packaging methods, which have the function of protecting products, preventing them from being affected by the outside world, and avoiding damage during transportation and storage. At the same time, the packaging can also mark the use information, quality indicators, production batch number, etc. on the product to improve the traceability and anti-counterfeiting of the product.

After-sales service: After-sales service is the company's attention and maintenance of products, and it is also an important means to improve customer satisfaction and loyalty. Star will provide relevant after-sales services, such as product usage guidance, question answering, return and exchange services, etc.