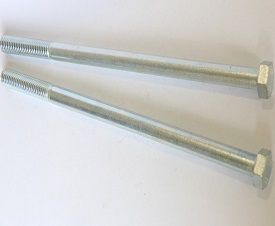

M12 Fine Thread Bolt

1.DIN 960 Hexagon Head Bolts with Fine Pitch Thread

2.Source bolt manufacturer, own factory: with price advantage, eliminating the price difference of middlemen.

3.Adopt the industry's top high-quality thickened steel, high stability and long-lasting durability.

4.Support customer customization.

5.Professional sales and after-sales service, welcome to inquire at any time.

6.Delivery on time.

M12 Fine Thread Bolt – Precision Fastening for High-Stress Applications

The M12 fine thread bolt is a specialized fastener designed for applications where precision, strength, and vibration resistance are crucial. With a nominal diameter of 12 millimeters and finer threads than standard bolts, the M12 fine thread bolt offers better tensile strength and tighter clamping force, making it ideal for critical assemblies in automotive, aerospace, and heavy machinery industries.

What is an M12 Fine Thread Bolt?

An M12 fine thread bolt features a 12mm shank diameter with thread pitch finer than the common coarse version. Fine threads have a smaller thread pitch (distance between each thread), which provides more threads per inch and increases the engagement surface with nuts or tapped holes.

This enhanced engagement allows the M12 fine thread bolt to resist loosening under vibration and endure high levels of tension—making it a preferred choice in dynamic and load-sensitive environments.

Advantages of Using M12 Fine Thread Bolt

✅ High Tensile Strength

The M12 fine thread bolt offers superior tensile capacity due to the increased thread engagement, ideal for parts that experience high loads.

✅ Vibration Resistance

The finer pitch allows better resistance to loosening under vibration. That’s why M12 fine thread bolts are often used in engine mounts, suspension systems, and structural frameworks.

✅ Precision Fit

Because of their thread density, M12 fine thread bolts provide more accurate alignment and are less prone to stripping during assembly or disassembly.

✅ Compact Design

In limited space applications, the M12 fine thread bolt can provide the same holding power as a larger coarse thread fastener without requiring oversized components.

Common Applications

The M12 fine thread bolt is widely used across industries that demand high performance and reliability. Common applications include:

Automotive assemblies – suspension components, brake calipers, engine parts

Heavy machinery – rotating parts, gearboxes, structural frames

Aerospace – aircraft engines, landing gear, cabin fittings

Construction – steel frame joints, bridges, reinforcement points

Industrial equipment – conveyor systems, pressure vessels, robotics

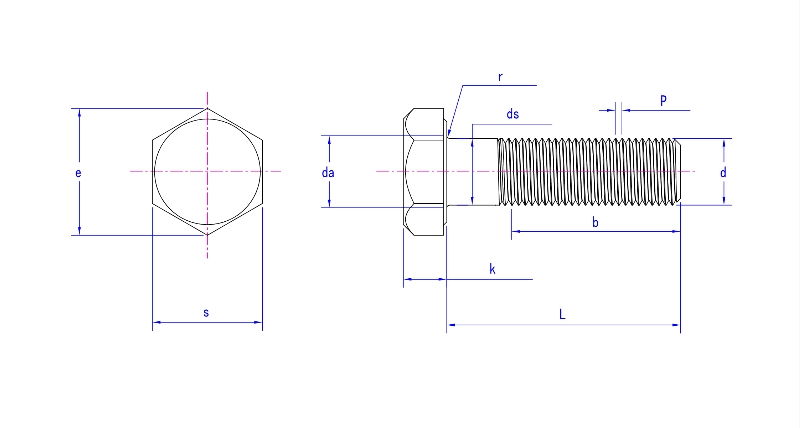

M12 Fine Thread Bolt Specifications

| Parameter | Description |

|---|---|

| Thread Type | Metric fine thread (e.g., 1.25 mm) |

| Material | Carbon steel, alloy steel, stainless steel |

| Coating Options | Zinc-plated, black oxide, hot-dip galvanized |

| Grade | 8.8, 10.9, or 12.9 for high strength |

| Length Range | 20mm to 150mm or customized |

| Standards | DIN 960, ISO 8676, ANSI compatible |

Installation Considerations

To get the most out of an M12 fine thread bolt, proper installation is crucial:

Use matching fine thread nuts or tapped holes.

Apply torque according to the bolt’s strength grade.

Use anti-seize or thread locker for environments exposed to corrosion or constant vibration.

Avoid cross-threading during initial engagement.

Conclusion

The M12 fine thread bolt is engineered for accuracy, strength, and reliability. Whether you are working on a complex automotive project, an industrial structure, or precision machinery, the M12 fine thread bolt delivers superior performance in demanding conditions. Its finer pitch, increased grip, and resistance to loosening make it a premium choice for engineers and builders who demand nothing but the best.

Product Drawing