ASME B18.2.3.4M Hex Head Flange Bolts

Product: ASME B18.2.3.4M Hex Head Flange Bolts

Property Class:4.6,4.8,5.6,5.8,8.8,10.9,12.9,

A2-70, A4-70,A4-80

Finish:Zinc Plating(Yellow Zinc, Zinc Blue, Rinse Color), Black, Phosphate & Oil, Zinc Phosphate, Hot-dip Galvanized(HDG),Dacromet, Geomet

Material:Steel

Export country: USA, Japan, Australia, Europe and so on

Support customer customization

ASME B18.2.3.4M is a standard established by the American Society of Mechanical Engineers (ASME) that specifies the dimensions, materials, properties and other requirements for hexagonal head flange bolts. The head of the bolt is designed in a hexagonal shape, making it easy to tighten with wrenches, screwdrivers and other tools. There is an enlarged flange surface (also called the load-bearing surface or gasket surface) under the bolt head. This flange surface is usually in contact with the surface of the flange or other connection to provide a larger contact area, thereby increasing the load-bearing capacity and sealing performance of the connection.

Pictures

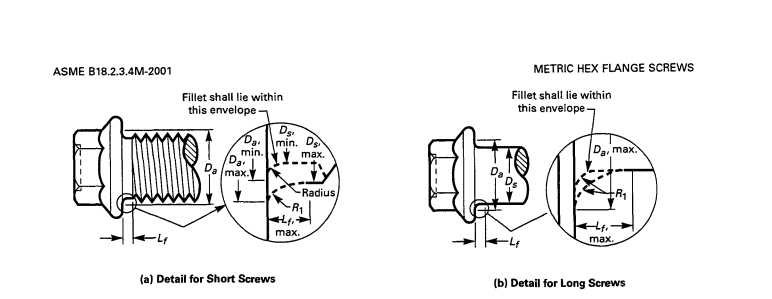

Product drawing

Product Specification

Gaging of Head | M5 | M6 | M8 | M10 | M12 | M14 | M16 | |

Wa | max | 8.09 | 9.25 | 11.56 | 15.02 | 17.33 | 20.79 | 24.26 |

min | 8.08 | 9.24 | 11.55 | 15.01 | 17.32 | 20.78 | 24.25 | |

Ta | max | 2.30 | 2.90 | 3.80 | 4.30 | 5.40 | 5.60 | 6.80 |

min | 2.29 | 2.89 | 3.79 | 4.29 | 5.39 | 5.59 | 6.79 | |

Wb | max | 7.43 | 8.55 | 10.79 | 14.07 | 16.31 | 19.67 | 22.57 |

min | 7.42 | 8.54 | 10.78 | 14.06 | 16.30 | 19.66 | 22.56 | |

Tb min | 3.0 | 3.0 | 4.0 | 4.0 | 5.0 | 5.0 | 6.0 | |

Support customer customization | ||||||||

Size type F | M5 | M6 | M8 | M10 | M12 | M14 | M16 | |

Da max | 5.7 | 6.8 | 9.2 | 11.2 | 13.7 | 15.7 | 17.7 | |

Da min | for short | 5.1 | 6.2 | 8.3 | 10.2 | 12.2 | 14.1 | 16.5 |

Ds min | for short | 4.36 | 5.21 | 7.04 | 8.86 | 10.68 | 12.50 | 14.50 |

Lf max | for long | 1.4 | 1.6 | 2.1 | 2.1 | 2.1 | 2.1 | 3.2 |

for short | 0.7 | 0.9 | 1.1 | 1.2 | 1.3 | 1.4 | 1.6 | |

R1 min | 0.2 | 0.25 | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | |

Support customer customization | ||||||||

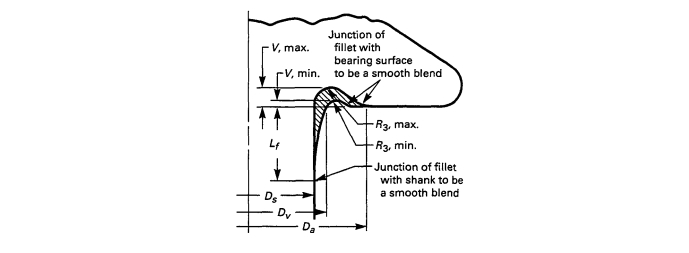

Size type U | M5 | M6 | M8 | M10 | M12 | M14 | M16 | |

Da max | 6.2 | 7.5 | 10.0 | 12.5 | 15.2 | 17.7 | 20.5 | |

Dv max | 5.5 | 6.6 | 8.8 | 10.8 | 12.8 | 14.8 | 17.2 | |

Ds min | for short | 4.36 | 5.21 | 7.04 | 8.86 | 10.68 | 12.50 | 14.50 |

Lf max | 1.4 | 1.6 | 2.1 | 2.1 | 2.1 | 2.1 | 3.2 | |

R3 | max | 0.25 | 0.26 | 0.36 | 0.45 | 0.54 | 0.63 | 0.72 |

min | 0.10 | 0.11 | 0.16 | 0.20 | 0.24 | 0.28 | 0.32 | |

V | max | 0.15 | 0.20 | 0.25 | 0.30 | 0.35 | 0.45 | 0.50 |

min | 0.05 | 0.05 | 0.10 | 0.15 | 0.15 | 0.20 | 0.25 | |

Support customer customization | ||||||||

Some introduction about our company

Application

Jinan Star Company specializes in the production of fastener products. Our bolts, nuts and other products are widely used in machinery, railways, automobiles, construction, electrical, bridges, communications, firefighting and other industries.

Certification

Jinan Star Fastener Co., Ltd. has obtained the 2015 version of ISO9001 quality management system certification through the scientific management of leaders of various departments and the pursuit of high quality for bolts and other fasteners. In addition, the laboratory affiliated to Star Company has obtained certification in 2017. In 2018, it passed the national CNAS certification, and in 2018, the company passed the European CE certification.

Workshop

The workshop of Jinan Star Fastener Co., Ltd. is the core area of the company's production and manufacturing, with advanced production equipment. The reasonable layout of the workshop and the scientific production process ensure the efficient production and high-quality output of fastener products.

Testing Equipment

Jinan Star Fastener Company attaches great importance to product quality and is equipped with complete quality inspection equipment, such as tensile testing machines, torque testers,metallographic microscopes, optical projectors, salt spray test chambers, coating thickness gauges, etc., which are used to test the tensile strength and elongation of fastener products and evaluate the mechanical properties of products. These equipment ensure that every link from raw materials to finished products can be strictly controlled in quality.

Production equipment

In order to meet the needs of different customers, the company has introduced a series of advanced production equipment, such as multi-station cold heading machines, thread rolling equipment, heat treatment equipment, shot blasting machines, sand blasting machines, electroplating lines and other surface treatment equipment, and fully automatic packaging equipment. These equipment not only improve production efficiency, but also ensure the consistency and stability of product quality.

Packing

Service

1. Product customization development: Xingchen can provide personalized product customization services according to the specific needs of customers. This includes product design and development based on application environment, material requirements, dimensional specifications and other parameters to meet the specific needs of customers.

2. Standard parts wholesale service: Xingchen usually provides standard parts wholesale services to facilitate customers to quickly purchase the products they need. This includes providing detailed product information and stock status so customers can easily check and place orders. At the same time, manufacturers cooperate with multiple logistics companies to ensure that products can be delivered to customers safely and on time.

FAQ

1. Can you send a price list?

sure. Simply leave your email here and we will send a price list within 2 business hours.

2. How do you control the quality?

We require QC to inspect every production link of each batch of goods. After the goods are completed, we can provide you with MTC and factory certificate.

3. Can I get some samples?

For new customers, we can provide standard fastener samples for free, but customers will pay the express cost. For old customers, we will send you samples for free, and the express cost will be paid by ourselves.