Square Neck Carriage Bolts

1.GB 12 Cup Head Square Neck Bolts

2.Source bolt manufacturer, own factory: with price advantage, eliminating the price difference of middlemen.

3.Adopt the industry's top high-quality thickened steel, high stability and long-lasting durability.

4.Support customer customization.

5.Professional sales and after-sales service, welcome to inquire at any time.

6.Delivery on time.

Square neck carriage bolts are specialty fasteners widely used in woodworking, structural framing, infrastructure, and general-purpose applications that require secure, anti-rotation fastening with a smooth, tamper-resistant head. Known for their iconic round head and square shank, these bolts offer aesthetic, mechanical, and security advantages in a variety of load-bearing or high-vibration environments.

This article offers a complete technical guide to square neck carriage bolts, covering materials, specifications, mechanical principles, standards, installation tips, and procurement advice.

Table of Contents

What Is a Square Neck Carriage Bolt?

Structural Design and Functional Advantages

Engineering Specifications and Standard Sizes

Materials and Coating Options

International Standards and Regulatory Compliance

Key Industrial Applications

Installation Best Practices and Safety Tips

Frequently Asked Questions (FAQs)

Conclusion and Call to Action

1. What Is a Square Neck Carriage Bolt?

A square neck carriage bolt—also referred to simply as a carriage bolt, coach bolt, or round head square neck bolt—is a type of bolt featuring:

A domed (round) head with no driving recess (e.g., slot or hex)

A short square section beneath the head

A partially threaded shank

The square neck locks into a mating square hole or embeds into softer materials such as wood, preventing rotation while the nut is tightened.

2. Structural Design and Functional Advantages

Key Design Elements:

Round Head: Provides a smooth, finished appearance and tamper resistance.

Square Neck: Prevents bolt rotation during nut tightening and offers anti-vibration reliability.

Threaded Shank: Typically features coarse threads for strong load-bearing capacity in structural applications.

Engineering Benefits:

Vibration-Resistant Locking in dynamic joints

Tamper-Resistant Installations in public-facing structures

One-Sided Assembly—only the nut side requires access

Fast and Secure Fit into wood, plastic, or punched steel with square holes

3. Engineering Specifications and Standard Sizes

Dimensional Standards:

Compliant with:

ASME B18.5 (Inch Series)

ASME B18.5.2.1M (Metric Series)

DIN 603 / ISO 8677

Common Size Ranges:

| Parameter | Range / Examples |

|---|---|

| Diameter | M6 – M20 (metric), 1/4" – 3/4" (imperial) |

| Lengths | 16 mm – 300 mm / 1" – 12" |

| Thread Type | Metric (coarse) / UNC (coarse) |

| Head Diameter (approx.) | 1.4 × shank diameter |

| Thread Length | Typically 2 × diameter or partial thread |

| Neck Height | 0.2 – 0.4 × shank diameter |

Head Ø ~24 mm

Square neck ~10 mm wide × 6 mm high

Partial thread (typically ~26–30 mm)

4. Materials and Coating Options

Common Materials:

| Material | Characteristics | Typical Use Cases |

|---|---|---|

| Carbon Steel (Grade 4.6 / 8.8) | Cost-effective, strong | General construction, wood joining |

| Stainless Steel (A2-70 / A4-80) | Excellent corrosion resistance | Marine, food-grade, outdoor structures |

| Brass or Bronze | Conductive, corrosion-resistant, decorative | Architectural, low-voltage applications |

| Alloy Steel (10.9 / 12.9) | High-tensile strength | Machinery and structural metal joints |

Zinc-Plated (Clear/Yellow) – Indoor corrosion resistance

Hot-Dip Galvanized – High outdoor durability (ISO 1461 compliant)

Black Oxide – Low-cost aesthetic coating

Passivated Stainless – Enhanced corrosion resistance (ASTM A967)

? Tip: Match coating type with the material it contacts to prevent galvanic corrosion.

5. International Standards and Regulatory Compliance

Dimensional & Mechanical Standards:

| Standard | Description |

|---|---|

| ASME B18.5 / B18.5.2.1M | Carriage bolt geometry and tolerance |

| DIN 603 / ISO 8677 | Metric series round head bolts |

| ISO 898-1 | Mechanical properties of fasteners |

| ASTM A307 / A193 | Steel and stainless steel bolts |

RoHS / REACH for hazardous substance limits

CE Marking if used in structural assemblies within EU

ISO 9001:2015 certified production recommended for traceability

6. Key Industrial Applications

| Industry | Application Examples |

|---|---|

| Woodworking & Carpentry | Beam connections, cabinetry, fence assembly |

| Construction & Infrastructure | Highway guardrails, decking, handrails |

| Furniture Manufacturing | Knock-down furniture, flat-pack kits |

| Marine Equipment | Boat docks, pier structures (A4 SS) |

| Electrical Enclosures | Non-conductive bolt-down installations |

| Playgrounds / Parks | Public installations with tamper resistance |

7. Installation Best Practices and Safety Tips

Installation Steps:

Drill or punch a matching hole (round or square) in the mating surface.

Insert the bolt so the square neck fits snugly.

Tap gently with a mallet to embed square neck (in wood or soft metal).

Install washer and nut on the opposite side.

Tighten using a torque wrench or spanner to specified torque.

Safety Notes:

Use locking nuts or washers if subject to high vibration.

Avoid over-torqueing in softwood to prevent pull-through.

For stainless steel fasteners, use anti-seize compound to prevent galling.

8. Frequently Asked Questions (FAQs)

Q1: Can square neck carriage bolts be used in steel structures?

Yes—if paired with square or slotted holes or by adding anti-rotation measures like ribbed necks or locking plates.

Q2: Are these bolts tamper-proof?

They are tamper-resistant, thanks to the smooth, tool-less head. For full tamper-proofing, consider shear or security-head bolts.

Q3: What is the recommended torque?

Follow torque tables based on ISO 898-1 (metric) or ASTM A307/A325 (imperial). Example: M10 Grade 8.8 = ~49 Nm.

Q4: Can I reuse them?

Yes, if threads and square neck integrity are intact. Replace if damaged or worn.

Q5: How do I prevent corrosion in outdoor installations?

Use hot-dip galvanized or A4-80 stainless steel versions and avoid dissimilar metal contact.

9. Conclusion and Professional Call to Action

Square neck carriage bolts are indispensable in structural, aesthetic, and secure fastening applications. With their round head design, square neck anti-rotation feature, and compliance with global fastener standards, they offer:

Easy one-side installation

Secure locking into wood or preformed holes

Clean, tamper-resistant appearance

Long-term durability when paired with proper materials

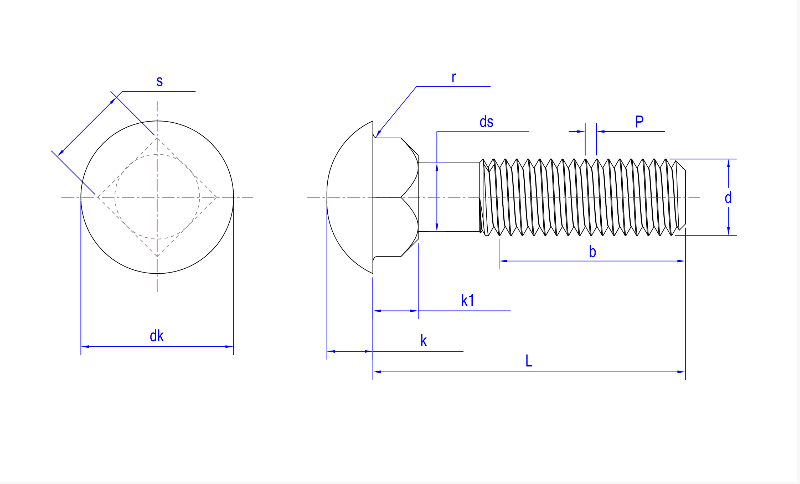

Product drawing