Bolt Round Head Square Neck

1.ASME B18.5-2 Round Head Square Neck Carriage Bolts

2.Source bolt manufacturer, own factory: with price advantage, eliminating the price difference of middlemen.

3.Adopt the industry's top high-quality thickened steel, high stability and long-lasting durability.

4.Support customer customization.

5.Professional sales and after-sales service, welcome to inquire at any time.

6.Delivery on time.

Round head square neck bolts are specialized mechanical fasteners widely used in woodworking, sheet metal fabrication, construction, and structural applications. These bolts offer enhanced anti-rotation performance, clean aesthetic finishes, and compatibility with square holes or soft materials. This article explores their engineering design, material options, applications, manufacturing standards, and selection guidelines.

Table of Contents

What Is a Round Head Square Neck Bolt?

Structural Design and Engineering Function

Technical Specifications and Dimensions

Materials and Surface Treatments

Industry Standards and Compliance

Industrial Applications

Installation Guidelines and Safety Considerations

Frequently Asked Questions (FAQs)

Conclusion and Professional Call to Action

1. What Is a Round Head Square Neck Bolt?

A round head square neck bolt, often referred to as a carriage bolt in North America, is a bolt with:

A domed or round head (smooth top, no drive).

A square neck section directly under the head.

The square neck prevents the bolt from turning during installation by embedding into the mating surface. These bolts are typically used with nuts and washers and are ideal for applications requiring vibration resistance and tamper-proof fastening.

? Alternate Names: Carriage Bolt, Coach Bolt, DIN 603 Bolt (Europe), Mushroom Head Bolt

2. Structural Design and Engineering Function

Key Functional Features:

Round Head: Prevents unauthorized removal and ensures a smooth, snag-free surface.

Square Neck: Locks into square holes or bites into soft material (like wood or plastic) to resist rotation.

Shank: Smooth or partially threaded; threading length is based on standards and grip requirements.

Engineering Advantages:

Vibration Resistance: The square neck secures against rotation in dynamic applications.

Aesthetic Finish: No exposed hex or slot on the head.

Tamper Resistance: Especially useful in public infrastructure or outdoor applications.

Ease of Installation: Requires access from one side only; suitable for blind installations.

3. Technical Specifications and Dimensions

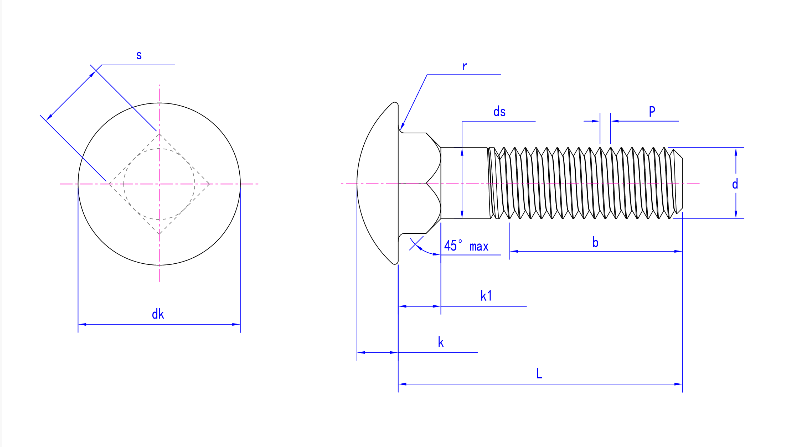

Typical Dimensional Parameters (per ASME B18.5.2.1M or DIN 603):

| Property | Metric Sizes (M6–M20) | Imperial Sizes (1/4"–3/4") |

|---|---|---|

| Head Diameter | 1.4× nominal diameter | – |

| Head Height | 0.3× nominal diameter | – |

| Square Neck Width | Equal to shank diameter | – |

| Thread Pitch | ISO Metric / UNC / UNF | UNC by default |

| Thread Length | Partial (depends on bolt length) | – |

| Tolerance Class | 6g / 6H (metric) | 2A / 2B (inch) |

10 mm nominal diameter

~50 mm total length

Threaded portion typically ~26–30 mm

Square neck width = 10 mm

Head diameter = ~24 mm

4. Materials and Surface Treatments

Common Materials:

| Material | Features | Applications |

|---|---|---|

| Carbon Steel (Grade 4.6/8.8) | Cost-effective, high tensile strength | General construction, wood joinery |

| Stainless Steel (A2/A4) | Corrosion-resistant, non-magnetic (A2) | Marine, food-grade, outdoor structures |

| Brass | Corrosion resistant, aesthetic appeal | Decorative fastening, low-voltage electrical |

| Alloy Steel (Grade 10.9/12.9) | High load capacity, heat treated | High-stress structural joints |

Zinc Plated (Blue/Yellow) – Moderate corrosion resistance

Hot-Dip Galvanized – For outdoor/heavy-duty use (ISO 1461)

Black Oxide – Light corrosion protection, aesthetics

Passivation (SS only) – Enhances stainless steel corrosion resistance

⚙️ Select materials based on environmental exposure, mechanical load, and galvanic compatibility with mating components.

5. Industry Standards and Compliance

Round head square neck bolts are manufactured according to international standards:

| Standard | Description |

|---|---|

| ASME B18.5.2.1M | Metric carriage bolts |

| ASME B18.5 | Inch series round head bolts |

| DIN 603 / ISO 8677 | European metric standards |

| BS 4933 | British standards for carriage bolts |

| RoHS / REACH | Material safety compliance (EU) |

| ISO 898-1 / ASTM A307 | Mechanical properties for carbon/alloy steel |

6. Industrial Applications

| Industry | Application Example |

|---|---|

| Construction | Securing wood beams, railings, and joists |

| Furniture Manufacturing | Flat-pack and DIY furniture joints |

| Public Infrastructure | Park benches, fencing, road signs |

| Marine & Offshore | Salt-resistant stainless variants |

| Automotive | Body panel attachment, truck bed assemblies |

| Electrical Enclosures | Tamper-proof fastening |

7. Installation Guidelines and Safety Considerations

Installation Steps:

Insert bolt through pre-drilled round or square hole.

Ensure square neck is fully embedded (tight fit or hammer flush if needed).

Use washer and nut on opposite side.

Tighten using a spanner or torque wrench to specification.

Safety Notes:

Do not overtighten in wood, which may cause fiber crush or pull-through.

For outdoor structures, use hot-dip galvanized or A4 stainless to avoid rust.

Ensure correct thread engagement — minimum 1.5× bolt diameter.

8. Frequently Asked Questions (FAQs)

Q1: Can I use round head square neck bolts in metal structures?

Yes, provided the square neck fits into a pre-punched square hole or high-friction surface. Otherwise, use locking washers or nuts.

Q2: Are carriage bolts tamper-proof?

They are tamper-resistant due to the smooth head. For true tamper-proofing, consider shear bolts or security heads.

Q3: What torque should I apply?

Refer to ISO 898-1 or ASME torque charts, depending on material grade and thread type.

Q4: Can these bolts be reused?

Yes, if undamaged. However, if thread deformation or neck wear occurs, replacement is recommended.

Q5: What’s the difference between DIN 603 and ASME B18.5 bolts?

DIN 603 bolts have metric threads and slightly different head dimensions compared to ASME bolts with imperial threads.

9. Conclusion and Professional Call to Action

Round head square neck bolts provide an effective, secure, and clean fastening solution for a variety of industries and structural applications. Whether used in timber framing, outdoor construction, or mechanical assembly, they offer:

Anti-rotation locking

Aesthetic head design

Wide material and size availability

Compliance with global standards

Product drawing