Round Head Short Square Neck Bolts ASME B18.5.2.1M

Product: Round Head Short Square Neck Bolts ASME B18.5.2.1M

Property Class:4.6,4.8,5.6,5.8,8.8,10.9,12.9,

A2-70, A4-70,A4-80

Finish:Zinc Plating(Yellow Zinc, Zinc Blue, Rinse Color), Black, Phosphate & Oil, Zinc Phosphate, Hot-dip Galvanized(HDG),Dacromet, Geomet

Material:Steel

Export country: USA, Japan, Australia, Europe and so on

Support customer customization

ASME B18.5.2.1M is a bolt and nut standard formulated by the American Society of Mechanical Engineers (ASME), specifically for the detailed specifications and dimensions of round head square neck bolts. Round head square neck carriage bolts have a round head and square neck, a design commonly used in applications that require a specific head shape and neck configuration. The square neck allows the use of specific tools, such as a wrench or wrench chuck, to turn the bolt, especially when head space is limited or when increased torque transfer efficiency is required. Round head square neck carriage bolts are commonly used in construction, mechanical engineering, automotive and other fields where high strength and reliable connections are required.

Pictures

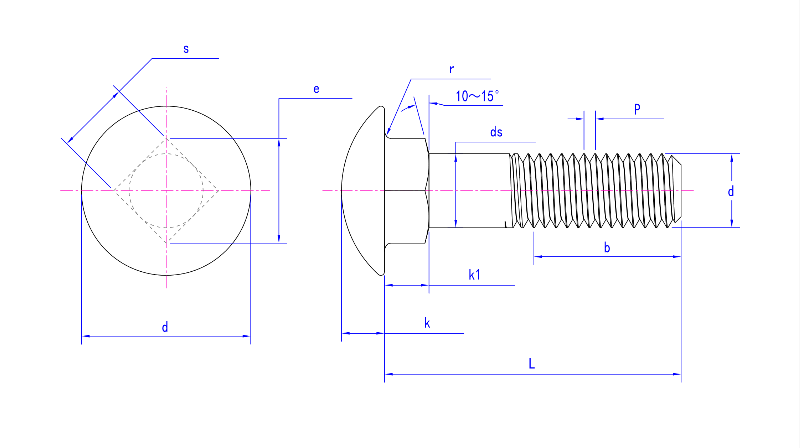

Product drawing

Product Specification

Size | M6 | M8 | M10 | M12 | M14 | M16 | M20 | |

P | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | |

da min | 12.2 | 15.8 | 19.6 | 23.8 | 27.6 | 31.9 | 39.9 | |

dc max | 14.2 | 18.0 | 22.3 | 26.6 | 30.5 | 35.0 | 43.0 | |

ds | max | 6 | 8 | 10 | 12 | 14 | 16 | 20 |

min | 5.21 | 7.04 | 8.86 | 10.68 | 12.50 | 14.50 | 18.16 | |

e | max | 9.16 | 12.13 | 14.96 | 17.96 | 20.79 | 23.62 | 29.74 |

min | 7.64 | 10.2 | 12.8 | 15.37 | 17.97 | 20.57 | 25.73 | |

k | max | 3.6 | 4.8 | 5.8 | 6.8 | 7.9 | 8.9 | 10.9 |

min | 3 | 4 | 5 | 6 | 7 | 8 | 10 | |

k1 | max | 3 | 3 | 4 | 4 | 4 | 5 | 5 |

min | 2.4 | 2.4 | 3.2 | 3.2 | 3.2 | 4.2 | 4.2 | |

r | max | 0.5 | 0.8 | 0.8 | 0.8 | 1.2 | 1.2 | 1.6 |

min | 0.2 | 0.4 | 0.4 | 0.4 | 0.6 | 0.6 | 0.8 | |

s | max | 6.48 | 8.58 | 10.58 | 12.7 | 14.7 | 16.7 | 20.84 |

min | 5.88 | 7.85 | 9.85 | 11.82 | 13.82 | 15.82 | 19.79 | |

Some introduction about our company

Application

Jinan Star Company specializes in the production of fastener products. Our bolts, nuts and other products are widely used in machinery, railways, automobiles, construction, electrical, bridges, communications, firefighting and other industries.

Round Head Short Square Neck Bolts, governed by ASME B18.5.2.1M, are a specialized category of fasteners designed for secure, tamper-resistant mechanical joints where low-profile heads and anti-rotation are essential. They are widely used in steel fabrication, automotive assembly, structural engineering, and heavy equipment manufacturing.

This technical guide covers the material specifications, dimensions, applications, tolerances, regulatory considerations, and installation guidelines for ASME B18.5.2.1M bolts, ensuring proper selection, compliance, and usage across industries.

Table of Contents

What Are Round Head Short Square Neck Bolts?

Overview of ASME B18.5.2.1M Standard

Dimensional Specifications

Materials and Mechanical Properties

Applications and Engineering Considerations

Installation Guidelines and Safety Notes

Regulatory Compliance and Industry Standards

Common Issues and Mitigation Strategies

Frequently Asked Questions (FAQs)

Conclusion & Professional Call to Action

1. What Are Round Head Short Square Neck Bolts?

Round Head Short Square Neck Bolts are metric fasteners with a rounded, low-profile head and a short square neck just beneath the head. The square neck provides anti-rotation capability by engaging with pre-punched square holes or embedding into soft substrates like wood or mild steel.

Key Features:

Low-profile dome-shaped head (non-wrenchable)

Short square neck prevents rotation during tightening

Typically used with a nut or threaded into a tapped hole

Metric design per ASME B18.5.2.1M

These bolts are often categorized as carriage bolts in layman terms, though they are differentiated by neck length, head height, and dimensional tolerance.

2. Overview of ASME B18.5.2.1M Standard

The ASME B18.5.2.1M standard governs the dimensions, mechanical properties, thread requirements, and manufacturing tolerances for round head short square neck bolts in metric units. It aligns with ISO metric thread profiles per ASME B1.13M.

Scope of ASME B18.5.2.1M:

Nominal sizes: M5 to M20

Lengths: 12 mm to 150 mm, depending on diameter

Thread class: 6g, external metric thread

Tolerances: ISO 4759-1 for dimensional limits

Materials and heat treatment: Referenced per ASTM F568M (for mechanical properties)

3. Dimensional Specifications

| Bolt Size (Nominal) | Head Diameter (D) | Head Height (H) | Square Neck Width (W) | Square Neck Height (T) | Thread Pitch |

|---|---|---|---|---|---|

| M6 | 14 mm | 3.4 mm | 6.0 mm | 3.0 mm | 1.0 mm |

| M8 | 18 mm | 4.2 mm | 8.0 mm | 4.0 mm | 1.25 mm |

| M10 | 22 mm | 5.0 mm | 10.0 mm | 4.5 mm | 1.5 mm |

| M12 | 26 mm | 6.0 mm | 12.0 mm | 5.0 mm | 1.75 mm |

| M16 | 35 mm | 8.0 mm | 16.0 mm | 6.0 mm | 2.0 mm |

4. Materials and Mechanical Properties

Common Materials:

Carbon steel (Class 4.6, 5.8, 8.8)

Alloy steel (heat-treated for strength)

Stainless steel (A2-70, A4-80)

Zinc-plated, black oxide, HDG (Hot-Dip Galvanized) finishes for corrosion protection

Mechanical Properties (per ISO 898-1 / ASTM F568M):

| Property | Grade 4.6 | Grade 8.8 | Stainless A2-70 |

|---|---|---|---|

| Yield Strength | 240 MPa min | 640 MPa min | 450 MPa min |

| Tensile Strength | 400 MPa min | 800 MPa min | 700 MPa min |

| Elongation | ≥ 22% | ≥ 12% | ≥ 20% |

Electro-galvanized (Zn coating thickness 5–8 μm)

Hot-dip galvanizing (Zn coating ~50 μm, for outdoor structural use)

PTFE or Dacromet coating for chemical resistance

Passivation for stainless steel (per ASTM A380/A967)

5. Applications and Engineering Considerations

Round head short square neck bolts are particularly effective in applications where:

Vibration resistance is crucial (neck prevents bolt spin)

Aesthetics matter (low-profile head)

One-side access is preferred (e.g., through-hole applications)

Soft materials like wood or aluminum are used (neck embeds easily)

Common Industries:

Automotive brackets and panels

Railway and heavy transport components

Elevator and escalator framing

Wood-to-metal fastenings

Steel formwork systems

Machine guards and access panels

Engineering Tip: These bolts are not torque-transmitting, so do not use in applications requiring head engagement for torque application. Always pair with an appropriate nut or internally threaded member.

6. Installation Guidelines and Safety Notes

Installation Steps:

Insert the bolt into a pre-punched round or square hole.

The square neck bites into the base material to prevent rotation.

Tighten from the nut side using a torque wrench or impact driver.

Use flat washers if needed to distribute load on soft or coated surfaces.

Safety Considerations:

Avoid over-torquing—check torque values per material and grade

Do not substitute standard carriage bolts for ASME B18.5.2.1M in load-critical designs

Always ensure neck engagement is full to prevent spin-out

7. Regulatory Compliance and Industry Standards

| Standard | Description |

|---|---|

| ASME B18.5.2.1M | Dimensional specification for round head short square neck bolts (metric) |

| ASME B1.13M | Unified metric screw thread tolerances |

| ISO 898-1 / ASTM F568M | Mechanical property standards for carbon and alloy steel bolts |

| ISO 3506 | Stainless steel bolt grading |

| RoHS / REACH | Compliance for environmental safety and restricted substances |

| EN 15048-1 (optional) | CE-marking and declaration for structural bolts in non-preloaded assemblies |

8. Common Issues and Mitigation Strategies

| Problem | Likely Cause | Recommended Solution |

|---|---|---|

| Bolt spins during tightening | Hole too large / neck not engaged | Use precision punched holes, ensure interference fit |

| Corrosion at neck | Improper coating or environmental mismatch | Use HDG or stainless steel variants |

| Bolt head deformation | Excessive impact installation | Use proper torque control tools |

| Thread stripping | Use of undersized or unmatched nut | Match nut class (e.g., Grade 8 nut with 8.8 bolt) |

9. Frequently Asked Questions (FAQs)

Q1: What’s the difference between a round head and a button head bolt?

A round head is dome-shaped and defined by ASME B18.5 standards. A button head usually refers to socket screws per ASME B18.3, often featuring an internal hex drive.

Q2: Can these bolts be used for structural steel connections?

Yes, if mechanical properties meet project requirements (e.g., Grade 8.8), but ensure compliance with relevant structural codes such as EN 1090 or AISC.

Q3: Are custom lengths or coatings available?

Yes, most certified manufacturers offer custom length ranges, thread cutbacks, special coatings, and lot traceability.

Q4: Are these bolts reusable?

They can be reused under non-critical applications if undamaged, but for safety-critical or fatigue-loaded joints, replacement is advised after disassembly.

Q5: Are CAD drawings or 3D models available?

Yes. Certified suppliers typically provide STEP, DWG, or IGES files upon request, compliant with ASME tolerances.

10. Conclusion & Professional Call to Action

Round Head Short Square Neck Bolts (ASME B18.5.2.1M) offer engineers and designers a secure, anti-rotation fastening solution with clean aesthetics and predictable performance. Whether you are constructing prefabricated systems, framing industrial equipment, or assembling transportation components, these bolts deliver:

Reliable torque resistance via embedded necks

Compliance with strict dimensional and strength standards

Flexibility for use in wood, plastic, aluminum, and mild steel

Corrosion-resistant coatings for extended outdoor service life