Serrated Flange Bolt

1.QC-T 340 Hexagon Bolts with Serrated Flange for Automobile(L>150mm)

2.Source bolt manufacturer, own factory: with price advantage, eliminating the price difference of middlemen.

3.Adopt the industry's top high-quality thickened steel, high stability and long-lasting durability.

4.Support customer customization.

5.Professional sales and after-sales service, welcome to inquire at any time.

6.Delivery on time.

The serrated flange bolt is a critical component in mechanical assemblies requiring enhanced grip and vibration resistance. Engineered for high-strength fastening applications, these bolts integrate a wide flange under the head with radial serrations to create a locking effect against loosening forces. This article offers an in-depth, technically rich, and SEO-optimized overview of serrated flange bolts — detailing their materials, design principles, manufacturing standards, industrial uses, and compliance guidelines.

What Is a Serrated Flange Bolt?

A serrated flange bolt is a type of hex-head bolt that features an integrated, non-spinning flange at its base, with serrations (grooves) on the underside of the flange. These serrations bite into the mating surface when tightened, increasing friction and preventing self-loosening caused by vibration or torque backflow.

Key Structural Features

| Component | Description |

|---|---|

| Hexagonal Head | Allows for standard torque application using wrench or socket tools |

| Flange Base | Acts like a built-in washer to distribute load evenly |

| Radial Serrations | Provide a locking mechanism by embedding into the mating surface |

| Threaded Shank | Usually metric or UNC/UNF threading depending on regional standards |

Engineering Design Considerations

1. Torque-to-Tension Relationship

Serrated flange bolts create higher friction at the interface.

Requires adjusted torque values, typically 20–25% higher than smooth flange bolts.

2. Material Hardness Compatibility

Serrations can damage softer materials (e.g., aluminum).

Use with hardened mating surfaces or specify serration geometry accordingly.

3. Serration Angle and Pitch

Serration angles typically range from 45° to 60°.

Number of teeth and depth influence locking performance and surface integrity.

Common Materials and Coatings

| Material | Properties |

|---|---|

| Carbon Steel (Grade 8.8 / 10.9) | High tensile strength; suitable for structural applications |

| Stainless Steel (A2-70 / A4-80) | Corrosion-resistant; ideal for outdoor and chemical environments |

| Alloy Steel | Heat-treatable for high-stress or fatigue-sensitive installations |

Zinc-Plated: Basic corrosion protection

Geomet®/Dacromet®: Salt-spray resistant, environmentally friendly

Black Oxide: Light corrosion resistance with low glare

Hot Dip Galvanized: Heavy-duty rust prevention for outdoor applications

Industry Standards and Regulatory Compliance

| Standard | Region/Scope | Description |

|---|---|---|

| ISO 1665 | International | Specifies dimensions and mechanical properties for flange bolts |

| DIN 6921 / EN 1665 | EU | German/European standard for hex flange bolts |

| ASME B18.2.1 | North America | Covers dimensional tolerances for inch-series bolts |

| RoHS / REACH | EU Environmental Compliance | Ensures materials are free from harmful chemicals like lead or cadmium |

| ASTM A574 / SAE J429 | USA Mechanical Standards | Tensile, hardness, and chemical composition requirements |

✅ Vibration Resistance – Serrations reduce the risk of loosening under cyclical loads

✅ Integrated Washer Design – Eliminates the need for separate washers

✅ Faster Assembly – One-piece solution reduces inventory and installation time

✅ Even Load Distribution – Minimizes stress concentrations on clamping surfaces

✅ High Pull-Out Strength – Excellent for dynamic load-bearing joints

Common Industrial Applications

| Industry | Application |

|---|---|

| Automotive | Suspension systems, engines, body panels |

| Construction | Steel frameworks, scaffolding, bridges |

| Aerospace | Non-critical fastenings in cabin assemblies |

| Manufacturing | Heavy machinery, conveyor systems, hydraulic presses |

| Renewable Energy | Wind turbines, solar panel frames |

Design Tips and Precautions

Avoid using serrated flange bolts with painted or coated surfaces unless surface damage is acceptable.

Use thread-locking compounds only if specifically permitted by design tolerances.

Apply torque values according to frictional coefficient and material hardness to avoid over-tightening or galling.

In critical assemblies, consider torque-angle control tightening methods for consistent preload.

Frequently Asked Questions (FAQs)

Q1: Are serrated flange bolts reusable?

A: Generally yes, but serrated teeth may wear or damage the mating surface. Reusability depends on application stress and surface material.

Q2: Can they be used with washers?

A: It is not recommended. The serrated flange functions as an integrated washer. Using an additional washer can reduce locking performance.

Q3: Are there alternatives to serrated flange bolts for anti-vibration?

A: Yes, such as:

Nylon insert lock nuts

Nord-Lock washers

Prevailing torque nuts

However, serrated flange bolts offer integrated benefits in a single component.

Q4: What torque specifications should I follow?

A: Refer to ISO or DIN torque charts for specific grades and thread pitches. Adjust for friction if coating or lubrication is present.

Q5: Can serrated flange bolts be used in aluminum assemblies?

A: Yes, but with caution. Serrations can cut into soft aluminum. Consider using a non-serrated flange or specify a softer serration profile.

Example Use Case: Automotive Suspension Assembly

Specification:

M10 x 1.5 serrated flange bolt

Material: Grade 10.9 Zinc-plated

Torque: 50 Nm (adjusted for 0.15 μ friction coefficient)

Result:Improved vibration resistance

No need for additional washers

20% faster installation time on the production line

Conclusion

The serrated flange bolt is a highly efficient and reliable fastener for vibration-prone applications. Its integrated washer and locking features enhance clamping integrity, making it ideal for high-performance environments like automotive, industrial, and construction sectors. With compliance to ISO, DIN, and ASTM standards, serrated flange bolts offer a consistent and robust fastening solution across global markets.

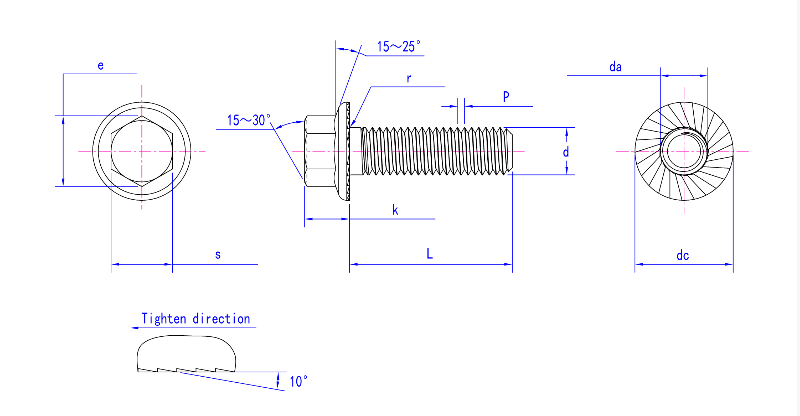

Product drawing