ASME B18.2.3.4M Metric Hex Head Flange Bolts

Product: ASME B18.2.3.4M Metric Hex Head Flange Bolts

Property Class:4.6,4.8,5.6,5.8,8.8,10.9,12.9,A2-70, A4-70,A4-80

Finish:Zinc Plating(Yellow Zinc, Zinc Blue, Rinse Color), Black, Phosphate & Oil, Zinc Phosphate, Hot-dip Galvanized(HDG),Dacromet, Geomet

Material:Steel

Export country: USA, Japan, Australia, Europe and so on

Support customer customization

ASME B18.2.3.4M is a standard developed by the American Society of Mechanical Engineers (ASME) that specifies the size, material, performance and other requirements of Hex Head Flange Bolts. The head of the bolt is designed to be hexagonal, which is convenient for tightening with tools such as wrenches and screwdrivers. There is an enlarged flange surface (also called the bearing surface or gasket surface) under the head of the bolt. This flange surface usually contacts the surface of the flange or other connecting parts to provide a larger contact area, thereby increasing the load-bearing capacity and sealing performance of the connection.

Pictures

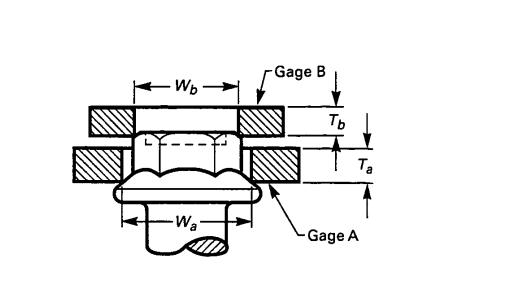

Product Head Drawing

Product Head Specification

Gaging of Head | M5 | M6 | M8 | M10 | M12 | M14 | M16 | |

Wa | max | 8.09 | 9.25 | 11.56 | 15.02 | 17.33 | 20.79 | 24.26 |

min | 8.08 | 9.24 | 11.55 | 15.01 | 17.32 | 20.78 | 24.25 | |

Ta | max | 2.30 | 2.90 | 3.80 | 4.30 | 5.40 | 5.60 | 6.80 |

min | 2.29 | 2.89 | 3.79 | 4.29 | 5.39 | 5.59 | 6.79 | |

Wb | max | 7.43 | 8.55 | 10.79 | 14.07 | 16.31 | 19.67 | 22.57 |

min | 7.42 | 8.54 | 10.78 | 14.06 | 16.30 | 19.66 | 22.56 | |

Tb min | 3.0 | 3.0 | 4.0 | 4.0 | 5.0 | 5.0 | 6.0 | |

Support customer customization | ||||||||

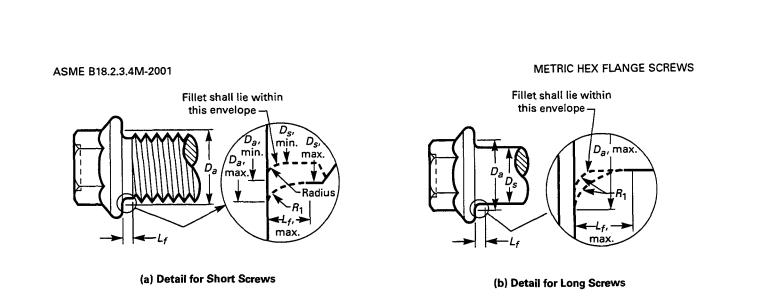

Product Type-F Drawing

Product Type-F Specification

Size type F | M5 | M6 | M8 | M10 | M12 | M14 | M16 | |

Da max | 5.7 | 6.8 | 9.2 | 11.2 | 13.7 | 15.7 | 17.7 | |

Da min | for short | 5.1 | 6.2 | 8.3 | 10.2 | 12.2 | 14.1 | 16.5 |

Ds min | for short | 4.36 | 5.21 | 7.04 | 8.86 | 10.68 | 12.50 | 14.50 |

Lf max | for long | 1.4 | 1.6 | 2.1 | 2.1 | 2.1 | 2.1 | 3.2 |

for short | 0.7 | 0.9 | 1.1 | 1.2 | 1.3 | 1.4 | 1.6 | |

R1 min | 0.2 | 0.25 | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | |

Support customer customization | ||||||||

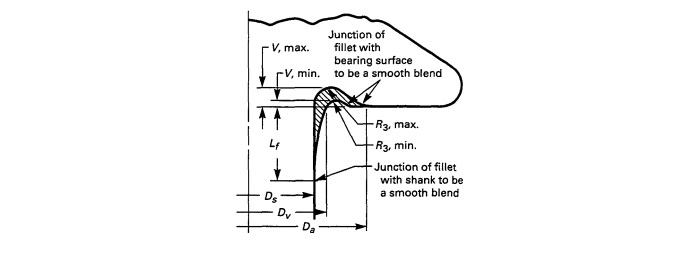

Product Type-U Drawing

Product Type-U Specification

Size type U | M5 | M6 | M8 | M10 | M12 | M14 | M16 | |

Da max | 6.2 | 7.5 | 10.0 | 12.5 | 15.2 | 17.7 | 20.5 | |

Dv max | 5.5 | 6.6 | 8.8 | 10.8 | 12.8 | 14.8 | 17.2 | |

Ds min | for short | 4.36 | 5.21 | 7.04 | 8.86 | 10.68 | 12.50 | 14.50 |

Lf max | 1.4 | 1.6 | 2.1 | 2.1 | 2.1 | 2.1 | 3.2 | |

R3 | max | 0.25 | 0.26 | 0.36 | 0.45 | 0.54 | 0.63 | 0.72 |

min | 0.10 | 0.11 | 0.16 | 0.20 | 0.24 | 0.28 | 0.32 | |

V | max | 0.15 | 0.20 | 0.25 | 0.30 | 0.35 | 0.45 | 0.50 |

min | 0.05 | 0.05 | 0.10 | 0.15 | 0.15 | 0.20 | 0.25 | |

Support customer customization | ||||||||

Some introduction about our company

Application

Our products are widely used in mechanical, electrical, automotive, building construction, railways, bridges, steamships, fire protection and communication system, etc.

Workshop

Certification

Through scientific management, Jinan Star Fastener Co., Ltd. has obtained the 2015 version of ISO9001 quality management system certification. In 2017, the laboratory passed the national CNAS certification. In 2018, the company passed the European CE certification.

Testing Equipment

Our company has a specialized laboratory with digital hardness testers, microscopes, universal testing machines, axial force meters, hydrogen embrittlement detection devices, magnetic particle flaw detectors, metallographic analyzers, carbon and sulfur analyzers and salt spray testing machines, etc. Experimental testing equipment is used to conduct comprehensive testing of the chemical composition of raw materials, product hardness, mechanical properties, coating thickness and corrosion resistance to ensure that all products meet standard requirements and satisfy customers.

Production equipment

Our company has more than 300 production equipment.The product production process includes: Annealing, shot blasting, cold heading, thread rolling, heat treatment, galvanizing, finished product testing, packaging, etc. are all completed in the company.

Packing

Service

1.Product customization and development: Star can provide personalized product customization services based on the specific needs of customers. This includes product design and development based on application environment, material requirements, size specifications and other parameters to meet the specific needs of customers.

2. Standard parts wholesale service: Star usually provides wholesale services for standard parts to facilitate customers to quickly purchase the required products. This includes providing detailed product information and inventory status, so that customers can easily query and place orders. At the same time, the manufacturer cooperates with a number of logistics companies to ensure that the products can be delivered to customers safely and on time.

FAQ

1.Can you send a price list?

Certainly. Just leave your email here and we will send a price list within 2 business hours.

2.How do you control your quality?

We require QC to inspect every production link of each batch of goods. We can provide you with MTC and factory certificate after the goods are completed.

3.Can I get some samples?

For new customers, we can provide standard fastener samples for free, but customers will pay the express cost. For old customers, we will send you samples for free and pay the express fee ourselves.