ASME B18.2.1-1 Square Head Bolts

Product: ASME B18.2.1-1 Square Head Bolts

Property Class: Gr307A, 307B, 325, A449, A490 2,5,8

Finish:Zinc Plating(Yellow Zinc, Zinc Blue,Rinse Color), Black, Phosphate & Oil, Zinc Phosphate, Hot-dip Galvanized(HDG),Dacromet, Geomet

Material:Steel

Export country: USA, Japan, Australia, Europe and so on

Support customer customization

ASME B18.2.1-1 is a standard developed by the American Society of Mechanical Engineers (ASME) that specifies the dimensions, materials, threads, and other characteristics of lag bolts (also known as square neck bolts or square shoulder bolts). A lag bolt is a bolt with a special head shape, usually square or rectangular, that is used in applications that require a wrench or similar tool for tightening or loosening. Square head bolts are widely used in situations where stable connection and easy disassembly are required, such as mechanical equipment, building structures, automobile manufacturing and other fields. They are often used in conjunction with a nut, which is tightened to create a clamping force that holds two or more parts together.

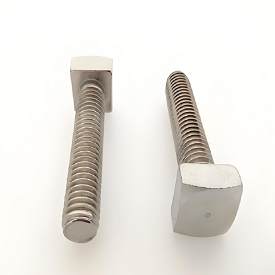

Pictures

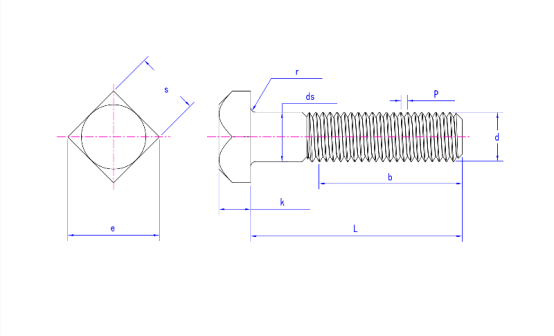

Product drawing

Product Specification

Size | 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | 5/8 | 3/4 | 7/8 | 1 | 1-1/8 | 1-1/4 | 1-3/8 | 1-1/2 | |

P | 20|28|32 | 18|24|32 | 16|24|32 | 14|20|28 | 13|20|28 | 11|18|24 | 10|16|20 | 9|14|20 | 8|12|20 | 7|12|18 | 6|12|18 | |||

ds | max | 0.26 | 0.324 | 0.388 | 0.452 | 0.515 | 0.642 | 0.768 | 0.895 | 1.022 | 1.149 | 1.277 | 1.404 | 1.531 |

min | 0.237 | 0.298 | 0.36 | 0.421 | 0.482 | 0.605 | 0.729 | 0.852 | 0.976 | 1.098 | 1.223 | 1.345 | 1.47 | |

s | min | 0.375 | 0.50 | 0.562 | 0.625 | 0.75 | 0.938 | 1.125 | 1.312 | 1.5 | 1.688 | 1.875 | 2.062 | 2.25 |

max | 0.362 | 0.484 | 0.544 | 0.603 | 0.725 | 0.906 | 1.088 | 1.269 | 1.45 | 1.631 | 1.812 | 1.994 | 2.175 | |

e | max | 0.53 | 0.707 | 0.795 | 0.884 | 1.061 | 1.326 | 1.591 | 1.856 | 2.121 | 2.386 | 2.652 | 2.917 | 3.182 |

min | 0.498 | 0.665 | 0.747 | 0.828 | 0.995 | 1.244 | 1.494 | 1.742 | 1.991 | 2.239 | 2.489 | 2.738 | 2.986 | |

k | max | 0.188 | 0.22 | 0.268 | 0.316 | 0.348 | 0.444 | 0.524 | 0.62 | 0.684 | 0.78 | 0.876 | 0.94 | 1.036 |

min | 0.156 | 0.186 | 0.232 | 0.278 | 0.308 | 0.400 | 0.476 | 0.568 | 0.628 | 0.72 | 0.812 | 0.872 | 0.964 | |

r | max | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.06 | 0.06 | 0.06 | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 |

min | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.02 | 0.02 | 0.02 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | |

Support customer customization | ||||||||||||||

Some introduction about our company

Application

Our products are widely used in mechanical, electrical, automotive, building construction, railways, bridges, steamships, fire protection and communication system, etc.

Workshop

Certification

Through scientific management, Jinan Star Fastener Co., Ltd. has obtained the 2015 version of ISO9001 quality management system certification. In 2017, the laboratory passed the national CNAS certification. In 2018, the company passed the European CE certification.

Testing Equipment

Our company has a specialized laboratory with digital hardness testers, microscopes, universal testing machines, axial force meters, hydrogen embrittlement detection devices, magnetic particle flaw detectors, metallographic analyzers, carbon and sulfur analyzers and salt spray testing machines, etc. Experimental testing equipment is used to conduct comprehensive testing of the chemical composition of raw materials, product hardness, mechanical properties, coating thickness and corrosion resistance to ensure that all products meet standard requirements and satisfy customers.

Production equipment

Our company has more than 300 production equipment.The product production process includes: Annealing, shot blasting, cold heading, thread rolling, heat treatment, galvanizing, finished product testing, packaging, etc. are all completed in the company.

Packing

FAQ

1.Standard compliance:

Answer: Our square head bolts fully comply with the ASME B18.2.1-1 standard, ensuring that the size, material, thread and other characteristics of the product meet the standard requirements.

material selection:

Answer: We provide lag bolts in a variety of materials, including carbon steel, stainless steel, alloy steel, etc., to meet the strength and corrosion resistance requirements in different application scenarios.

2. Dimensions:

Answer: We offer lag bolts in a variety of sizes, including different diameters, lengths and head sizes, to suit the connection needs of a variety of equipment and structures.

3. Application scenarios:

Answer: Square head bolts are widely used in mechanical equipment, building structures, automobile manufacturing and other fields. Our products can ensure stable connection and easy disassembly in these fields.

4. Accuracy level:

Answer: Our lag bolts are precisely sized and threaded to ensure reliability and accuracy when joining. We produce to the accuracy levels specified in the ASME B18.2.1-1 standard.

5. Replacement and compatibility:

Answer: If you need to replace existing lag bolts, we can provide the same or similar specifications and dimensions as the old bolts to ensure compatibility with existing systems.

6. Customized services:

Answer: We offer customization services and can produce lag bolts in special sizes, materials, or coatings based on your specific needs.