Double End Studs

1.GB 898 Double End Studs-bm=1.25d

2.Source bolt manufacturer, own factory: with price advantage, eliminating the price difference of middlemen.

3.Adopt the industry's top high-quality thickened steel, high stability and long-lasting durability.

4.Support customer customization.

5.Professional sales and after-sales service, welcome to inquire at any time.

6.Delivery on time.

Double End Studs: A Comprehensive Guide

Double End Studs are an essential component in many industrial and mechanical applications, offering a versatile and robust solution for securing materials together. These fasteners, characterized by threaded sections on both ends, are highly efficient in connecting components where both ends require secure threading. Commonly used in the construction, automotive, and manufacturing industries, Double End Studs are designed to provide strength, stability, and reliability across a wide range of projects.

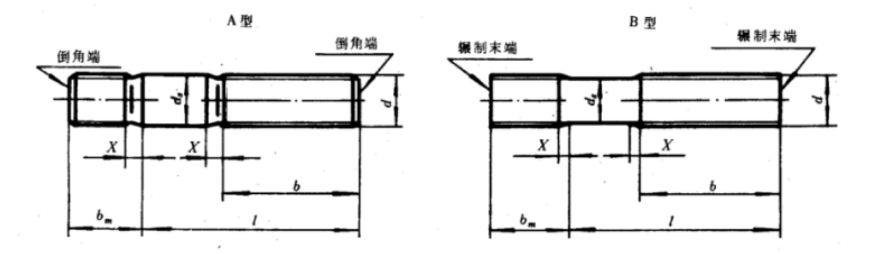

Pictures

Product drawing

Key Features of Double End Studs

Dual Threading for Versatile Application

Double End Studs are distinguished by their dual-thread design, with threads on both ends, allowing them to be securely installed into two components simultaneously. This makes them highly effective for applications that require threading into both ends of a material, providing a balanced and durable connection.Various Sizes and Lengths

Available in a wide range of sizes, lengths, and thread types, Double End Studs can be customized to fit specific application needs. Whether you require short studs for compact applications or longer studs for structural connections, these fasteners can be tailored to meet the demands of various industries.Durability and Corrosion Resistance

Made from materials such as stainless steel, carbon steel, and alloy steel, Double End Studs offer superior resistance to corrosion and wear. This durability ensures that they perform well in harsh environments, such as those found in construction, automotive, and marine applications, where exposure to moisture and other environmental factors is common.Strong Load-Bearing Capacity

With their robust construction and dual-thread design, Double End Studs are designed to handle high levels of stress and pressure. This makes them suitable for applications where the fasteners need to bear significant loads without compromising on stability or performance.

Advantages of Using Double End Studs

Enhanced Fastening Power

The dual threading of Double End Studs provides an enhanced grip and fastening power, as both ends of the stud engage with the materials, distributing the load more effectively. This feature makes them ideal for applications where securing both ends of a connection is critical for stability.Flexibility in Installation

Double End Studs are designed for ease of installation, allowing users to fasten materials from both ends with minimal tools. This flexibility streamlines the assembly process, making it faster and more efficient, especially in large-scale projects where time and accuracy are crucial.Reduced Material Stress

By providing a more evenly distributed load across the stud, Double End Studs help reduce stress concentrations in the materials being connected. This helps prevent damage to the materials and enhances the overall integrity of the connection.Cost-Effective Solution

Double End Studs offer a cost-effective fastening solution, as they eliminate the need for additional fasteners or nuts. By providing a secure connection with just one component, these studs reduce material and labor costs in a variety of applications.

Common Applications of Double End Studs

Automotive and Mechanical Systems

Double End Studs are commonly used in automotive and mechanical systems to secure engine components, exhaust systems, and other critical parts. Their ability to fasten components securely from both ends ensures that automotive systems maintain their integrity under high-pressure conditions.Construction and Structural Projects

In construction, Double End Studs are used for securing structural elements like beams, columns, and plates. Their ability to create strong, stable connections makes them ideal for high-stress environments, such as bridges, buildings, and other infrastructure projects.Furniture Manufacturing

In the furniture industry, Double End Studs are often used for connecting parts such as legs to frames, ensuring a firm and reliable bond. Their versatility in size and strength allows them to be used in both light-duty and heavy-duty furniture construction.Heavy Equipment and Machinery

Double End Studs are also widely used in heavy equipment and machinery applications, where components must be securely fastened to withstand vibrations, pressures, and heavy loads. These studs ensure that the connections remain stable and durable throughout the operational life of the equipment.

Why Choose Double End Studs?

Strong and Durable Connections

The dual-thread design of Double End Studs ensures that connections are both strong and reliable. The stud's robust material construction and even load distribution make it ideal for applications that demand long-lasting performance and stability.Ease of Use in Tight Spaces

Double End Studs can be installed in tight spaces where traditional fasteners might not fit. Their compact design allows for easy installation in areas with limited access, making them an essential tool for applications in confined spaces or complex assemblies.Improved Safety and Reliability

By providing a strong, secure connection, Double End Studs help improve the safety and reliability of the structures and systems they are used in. Whether securing machinery or construction elements, these studs ensure that the fasteners remain firmly in place, reducing the risk of failures or accidents.Customization Options

Double End Studs come in various configurations to suit specific needs. Customizable features, such as material choice, length, thread type, and coating, make it easy to tailor the studs to particular projects or environmental conditions, ensuring the best possible performance.

Conclusion: The Value of Double End Studs

In conclusion, Double End Studs are indispensable fasteners that provide superior strength, reliability, and versatility across a wide range of industries. Whether you're working on automotive repairs, construction projects, or furniture assembly, these studs offer a secure and cost-effective solution for all your fastening needs. Their unique dual-thread design and exceptional durability make them an ideal choice for both light-duty and heavy-duty applications, ensuring that components remain firmly in place over time.