JIS B1171 Cup Head Square Neck Bolts

Product: JIS B1171 Cup Head Square Neck Bolts

Property Class:4.6,4.8,5.6,5.8,8.8,10.9,12.9,A2-70, A4-70,A4-80

Finish:Zinc Plating(Yellow Zinc, Zinc Blue, Rinse Color), Black, Phosphate & Oil, Zinc Phosphate, Hot-dip Galvanized(HDG),Dacromet, Geomet

Material:Steel

Export country: USA, Japan, Australia, Europe and so on

Support customer customization

Carriage bolt,which has square neck, is stuck in the slot during installation and prevents the bolt from rotating.

Pictures

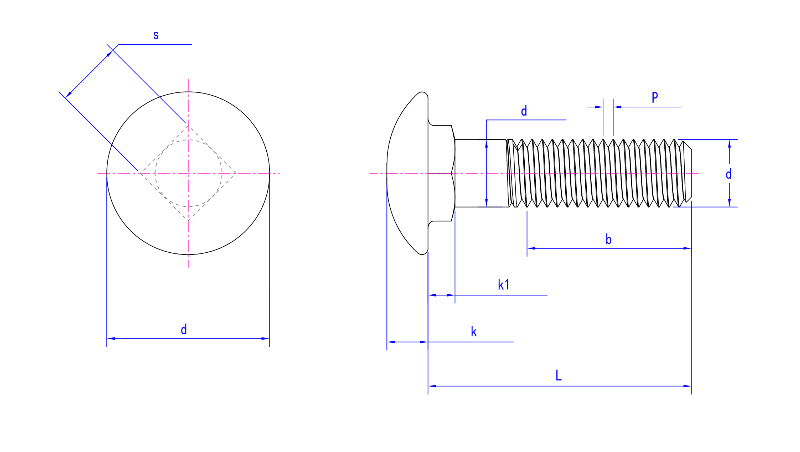

Product drawing

Product Specification

Size | M6 | M8 | M10 | M12 | M16 | M20 | |

P | 1 | 1.25 | 1.5 | 1.75 | 2 | 2.5 | |

dk max | 14.2 | 18 | 22.3 | 26.6 | 35 | 43 | |

ds | max | 6 | 8 | 10 | 12 | 16 | 20 |

k | max | 3.6 | 4.8 | 5.8 | 6.8 | 8.9 | 10.9 |

min | 3 | 4 | 5 | 6 | 8 | 10 | |

k1 | min | 2.4 | 2.4 | 3.2 | 3.2 | 4.2 | 4.2 |

max | 3 | 3 | 4 | 4 | 5 | 5 | |

s | max | 6.48 | 8.58 | 10.58 | 12.7 | 16.7 | 20.84 |

min | 5.88 | 7.85 | 9.85 | 11.82 | 15.82 | 19.79 | |

Support customer customization | |||||||

Some introduction about our company

Application

Our products are widely used in mechanical, electrical, automotive, building construction, railways, bridges, steamships, fire protection and communication system, etc.

Workshop

Certification

Through scientific management, Jinan Star Fastener Co., Ltd. has obtained the 2015 version of ISO9001 quality management system certification. In 2017, the laboratory passed the national CNAS certification. In 2018, the company passed the European CE certification.

Testing Equipment

Our company has a specialized laboratory with digital hardness testers, microscopes, universal testing machines, axial force meters, hydrogen embrittlement detection devices, magnetic particle flaw detectors, metallographic analyzers, carbon and sulfur analyzers and salt spray testing machines, etc. Experimental testing equipment is used to conduct comprehensive testing of the chemical composition of raw materials, product hardness, mechanical properties, coating thickness and corrosion resistance to ensure that all products meet standard requirements and satisfy customers.

Production equipment

Our company has greater than 300 manufacturing equipment.The product manufacturing method includes: Annealing, shot blasting, bloodless heading, thread rolling, warmth treatment, galvanizing, completed product testing, packaging, etc. are all accomplished in the company.

Packing

Our service:

1. Professional manufacturer: All our fasteners are designed and manufactured in accordance to buyers' specs and performance.

2. Quality guaranteed: sturdiness checking out and key technological know-how sketch to enhance the carrier lifestyles of fasteners.

3. Cost-effectiveness: Wide decision of parts, furnished via expert factories, and aggressive prices.

4. Customize best fasteners: Customize offerings primarily based on the samples and drawings provided.

5. Perfect fastening options with 60 years of journey to resolve your problems: wide selection of parts.

FAQ

1. Can I trust you?

We specialize in the production of fastener products, and our products are exported to Australia, Japan, Germany and other countries. At the same time, we maintain friendly long-term cooperative relationships with various manufacturers.

2. How do you control your quality?

We require QC to inspect every production link of each batch of goods. We can provide you with MTC and factory certificate after the goods are completed.

3. Do you accept small orders?

Of course, we can accept any order, and we keep large stocks of all products.

4. What is your packaging?

We can make customer's logo on the carton. Or we customize cartons according to customer needs.